Formaldehyde gas generating device based on paraformaldehyde emission depolymerization

A technology of paraformaldehyde and formaldehyde gas, which is applied in the preparation of carbon-based compounds, the preparation of organic compounds, chemical/physical/physical-chemical processes, etc. The effect of good thermal creep resistance and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

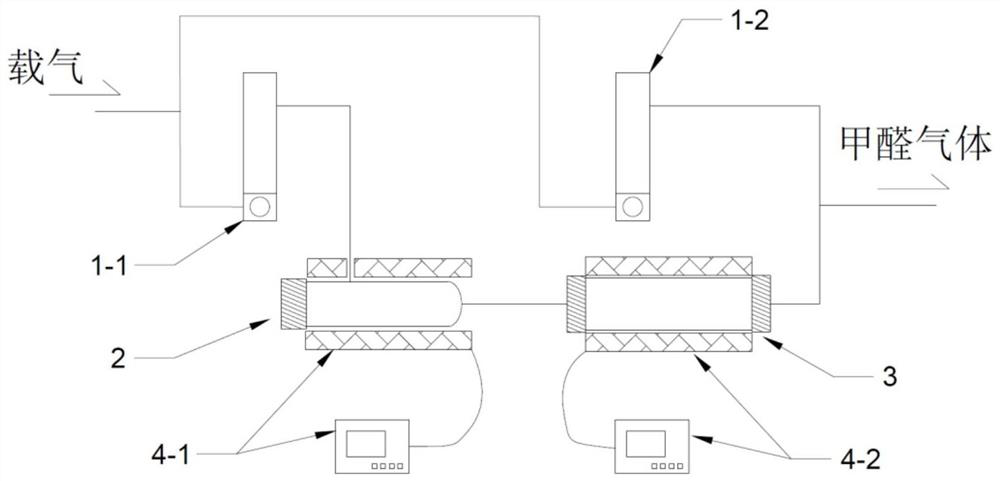

[0040] use as figure 1 In the device described above, a paraformaldehyde emission rod 13 is added to the emission chamber 2, the operating temperature of the emission chamber 2 is 35°C, the control temperature of the catalytic depolymerization chamber 3 is 220°C, and the actual chamber airflow temperature is about 168°C , using the RM-16 high-precision formaldehyde detector produced by the American interscan company to detect the formaldehyde concentration of the experimental system, and the stability of formaldehyde gas generation is obtained as follows: Figure 5 , the concentration fluctuation is within ±5% of the test standard requirements, meeting the test requirements. At the same time, the depolymerization rate was compared by the weighing method. The weight loss of the solid paraformaldehyde emission rod obtained by the weighing method was 4.3 mg before and after the experiment, and the actual cumulative emission of single-molecule formaldehyde detected by the instrume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com