Double-layer rotor for powder-liquid integrated delivery pump

An all-in-one, delivery pump technology, applied in transportation and packaging, control of mechanical energy, dissolution, etc., can solve the problems of high energy consumption cost, long production time, waste and other problems, achieve rapid repeated adjustment, shortest production time, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

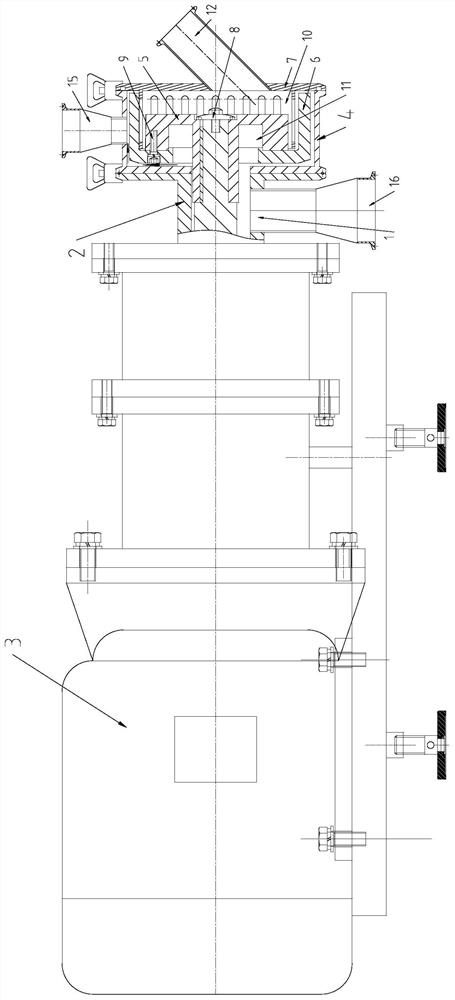

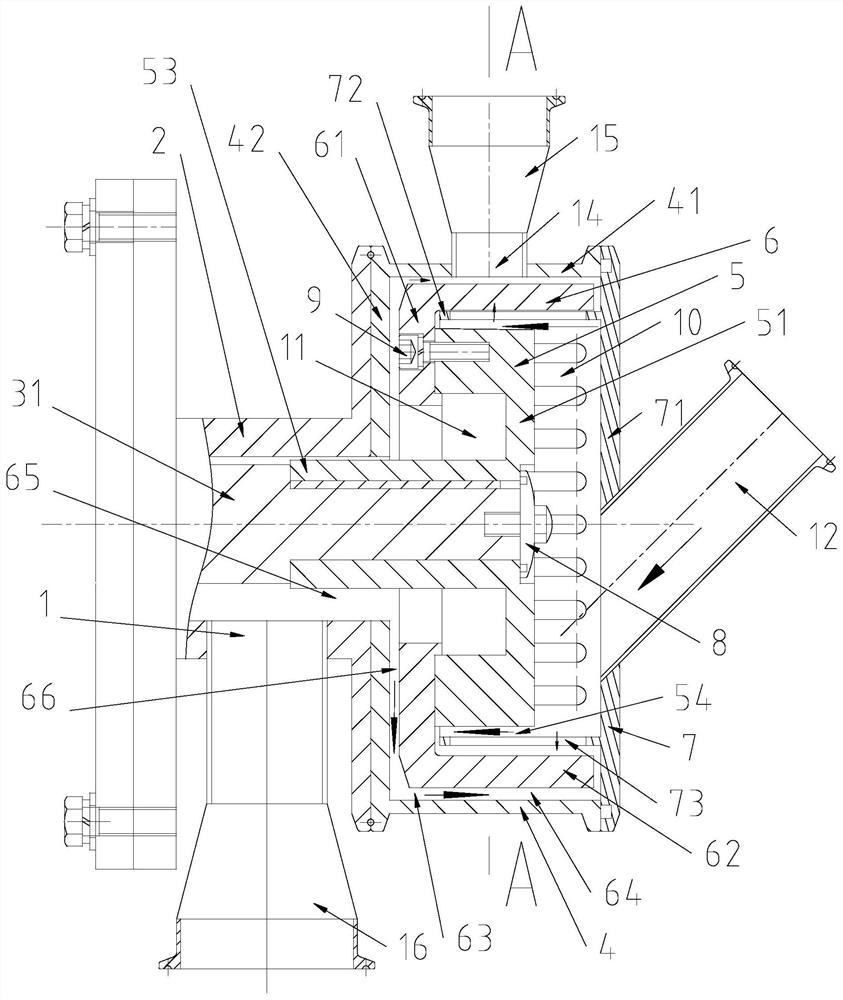

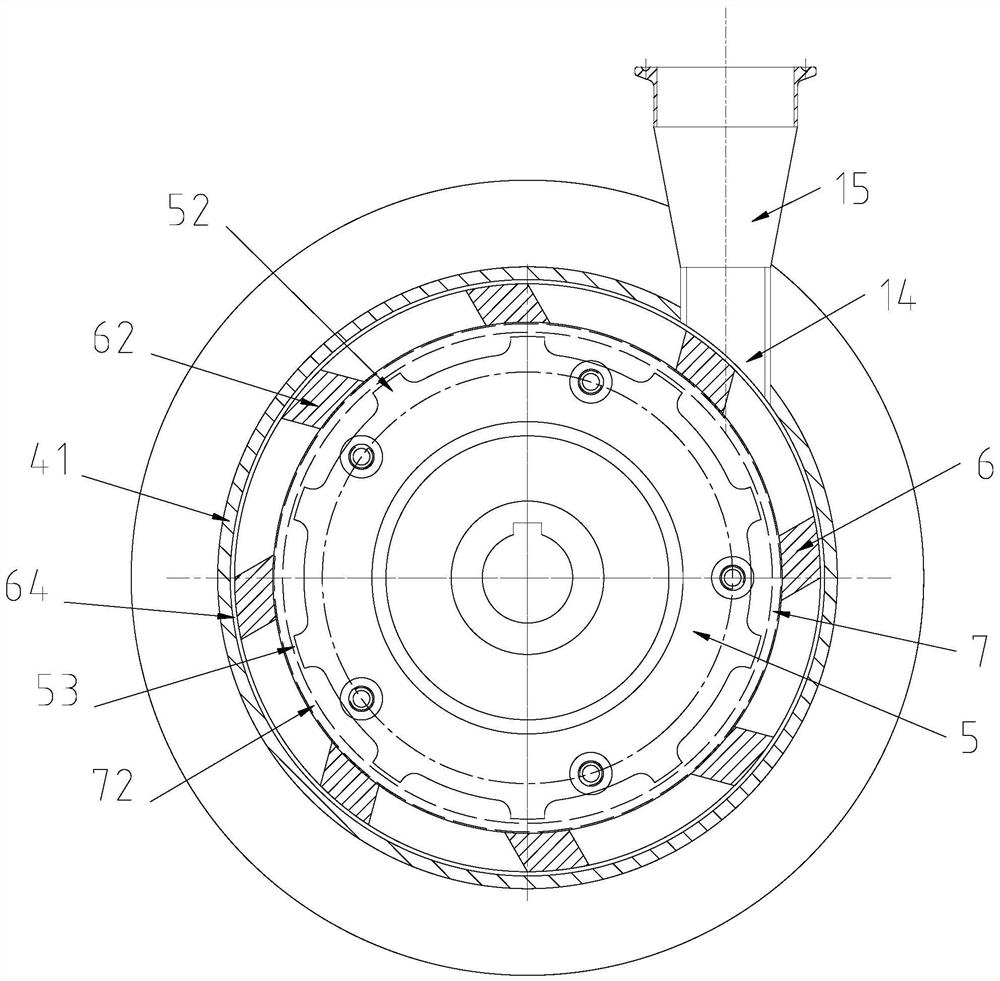

[0031] see figure 1 In the shown double-layer rotor used in the powder-liquid integrated delivery pump, the sleeve 2 is fixed on the motor 3 , and the motor has a rotating shaft 31 . Cylindrical housing 4 has an annular peripheral portion 41 and a cover plate 42 on the left side. The open right side of cylindrical housing 4 is sealed with an end cover 71, and ring 72 is arranged on end cover 71 (circular ring 72 and end cover 72 is integrally formed stator 7). The cover plate 42 of the casing 4 is sealed and fixedly connected with the sleeve 2 (of course, the sleeve 2 can also be regarded as a component of the casing 4).

[0032] The rotor includes an inner rotor 5 and an outer rotor 6 . The inner rotor 5 includes an integrally connected shaft segment 53 , an inner disc 51 , and inner teeth 52 , and the outer rotor 6 includes an integrally connected outer disc 61 and outer teeth 62 .

[0033] The shaft section 53 is connected with the rotating shaft 31 through a key, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com