Oil-gas separation device for internal combustion engine

A separation device, oil and gas separator technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of engine carbon deposition, air pollution, unqualified, etc. The effect of oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

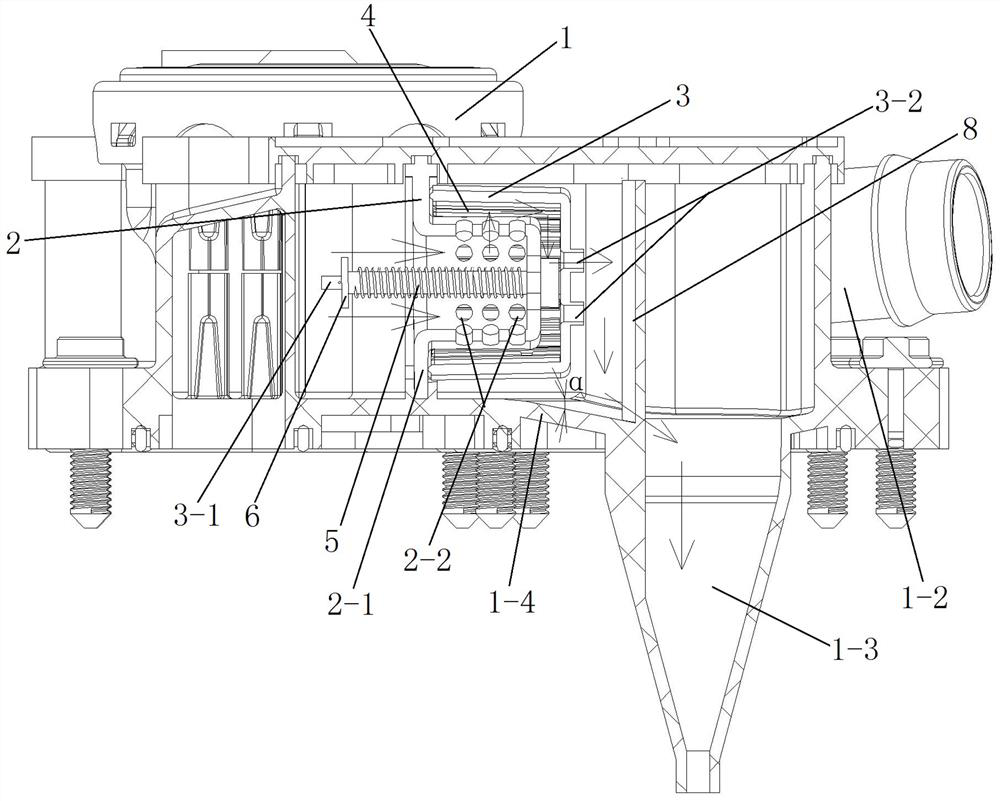

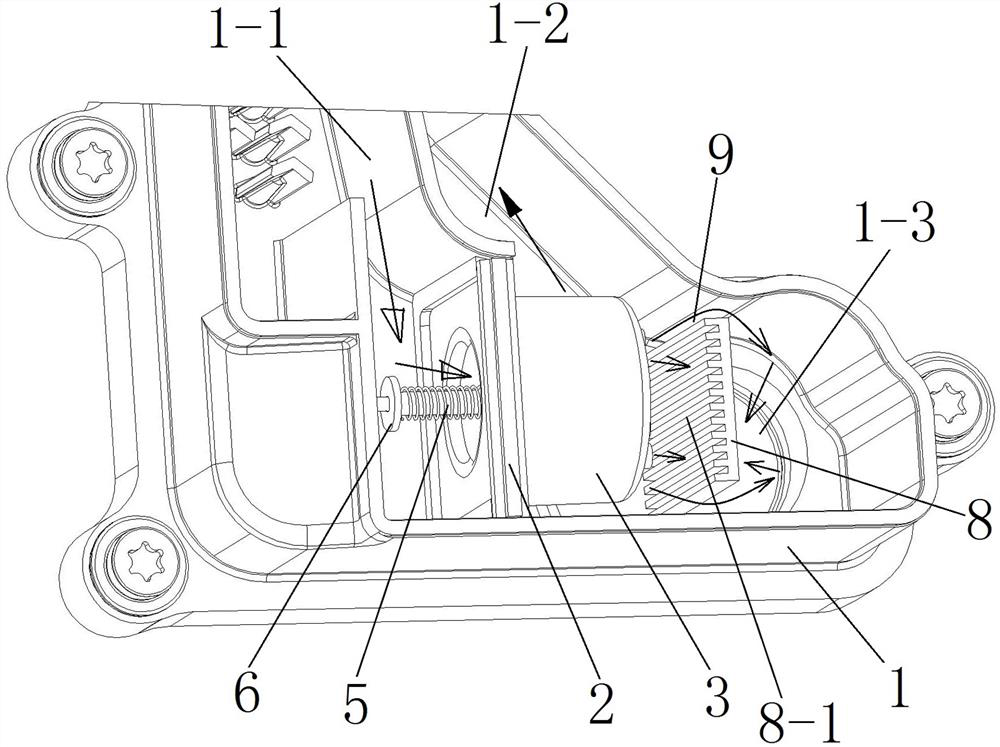

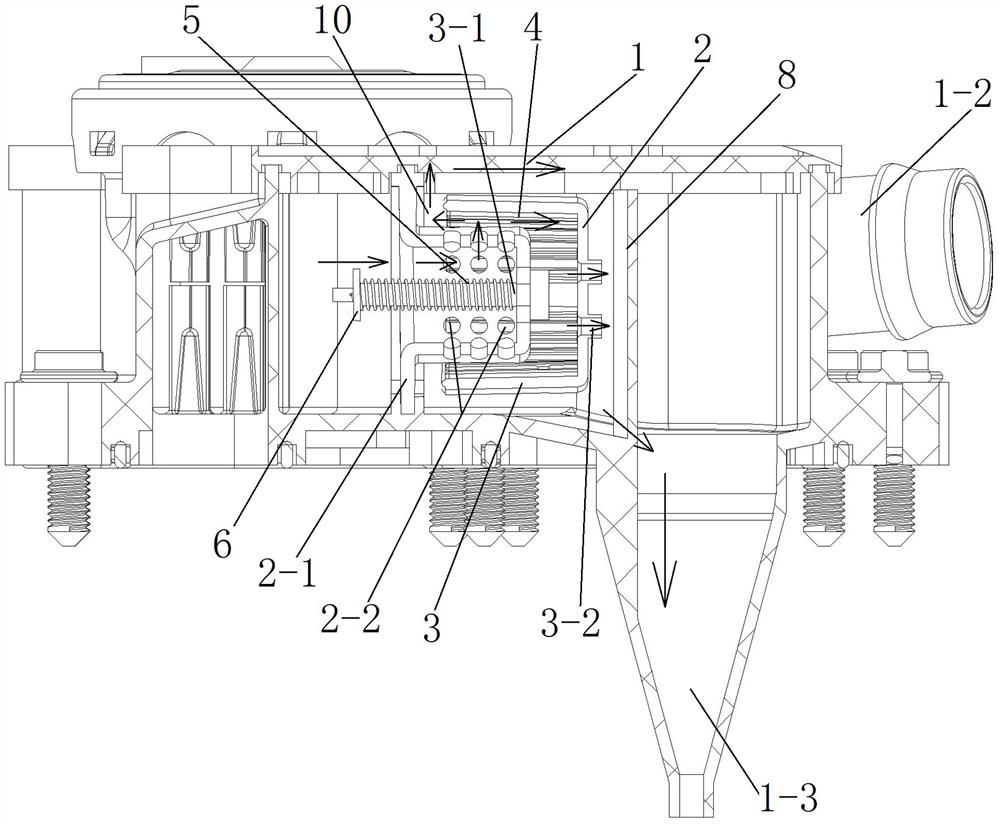

[0026] Refer to attached Figure 1-8 , an oil-gas separation device for an internal combustion engine, having a mounting base 1, an air intake passage 1-1 and an air outlet passage 1-2 are respectively arranged in the installation base 1, and the air intake passage 1-1 and the air outlet passage 1 An oil-air separator is installed at the intersection of -2, and an oil outlet channel 1-3 is also provided at the rear end of the oil-air separator for recovering the separated engine oil. A closed cover plate is installed above the installation base for Cover the air inlet passage 1-1, the air outlet passage 1-2, the oil-gas separator and the oil outlet passage 1-3.

[0027] The oil-gas separator has a cylindrical inner sleeve 2, and the outer wall of the inner sleeve 2 is provided with a matching outer sleeve 3; wherein the inner sleeve 2 has an outwardly turned flange 2-1, Corresponding slots are provided on the installation base 1, and the inner sleeve 2 can be clamped and inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com