Soil sampling device suitable for vertical shaft and sampling method

A vertical well and soil sample technology, which is applied to earth drilling, wellbore/well components, buildings, etc., can solve the problems of large soil disturbance and damage, complicated operation process, and low sampling success rate, so as to reduce potential safety hazards, The effect of improving sampling efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

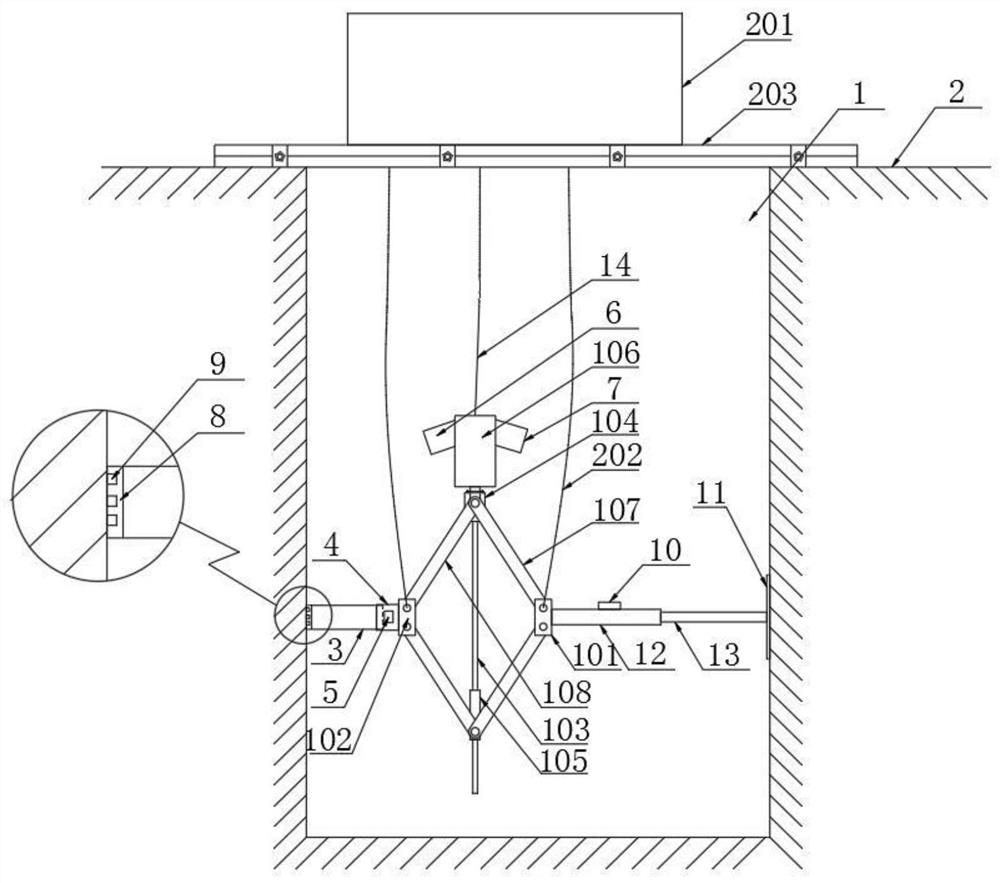

Embodiment 1

[0033] refer to figure 1, a kind of soil sampling device applicable to vertical shafts of the present invention comprises a sampling mechanism arranged in the vertical shaft and a lifting mechanism arranged on the top of the vertical shaft for driving the sampling mechanism to lift in the vertical direction; the sampling mechanism includes horizontally arranged For the support rod in the shaft, one end of the support rod is connected to the inner wall of the shaft 1, and the other end is connected to the inner wall of the shaft through the power mechanism and the hollow sampling tube 3 in turn; The support 101 and the second support 102, a screw 103 is vertically arranged between the first support 101 and the second support 102; the top of the screw is provided with a connecting seat 104 fixedly connected to the screw, and the end of the connecting seat is connected Motor 106; The threaded sleeve 105 that is provided with the screw thread matching of screw rod on the screw rod...

Embodiment 2

[0043] Sampling method adopts a kind of soil sampling device applicable to shafts described in embodiment one, comprising the following steps:

[0044] S1. According to the diameter of the shaft, the length of the support rod is adjusted by rotating the support rod, so that the overall length of the sampling mechanism is slightly smaller than the diameter of the shaft;

[0045] S2. Set up the lifting mechanism on the top of the shaft, and lower the sampling mechanism to the predetermined sampling position through the lifting mechanism;

[0046] S3, observe the levelness of the sampling mechanism by a spirit level, adjust different wire ropes to keep the sampling mechanism in a horizontal state; then observe the contact situation between the sampling pipe and the backing plate and the inner wall of the shaft through the first camera and the second camera;

[0047] S4. Drive the sampling pipe through the power mechanism to steadily and slowly press the soil body in the shaft unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com