Bending and shearing mixed type square steel tube damper and manufacturing method

A square steel pipe and hybrid technology, applied in building types, building components, earthquake resistance, etc., can solve problems such as high cost, unsuitable for low-level multi-storey building applications, complex structures, etc., achieve good integrity, avoid unstable welding quality, Design flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

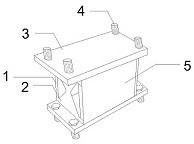

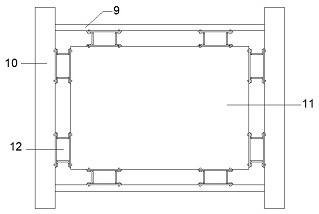

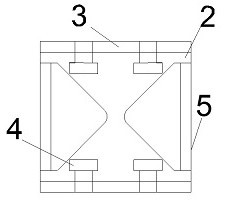

[0032] The following is attached Figure 1-10 , to illustrate the preferred embodiments of the present invention, it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0033] Figure 1-10 As shown, the bending-shear hybrid square steel pipe damper of the present invention is mainly composed of square steel pipes, bending energy dissipation plates, flange restraint plates, and connecting bolts. Among them, the square steel pipe is made of Q235 steel, low yield point steel, etc., and the low yield point seamless steel pipe is preferred; the side of the square steel pipe is the shear energy dissipation surface, which can bear the shear load energy consumption; the welding bending loss at both ends of the shear energy dissipation surface Energy plate, the bending energy dissipation plate is X-shaped, which can bear the bending load and energy dissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com