Soda type saline-alkali soil improver and improvement method

A technology of improving and improving agent for saline-alkali soil, applied in the fields of land preparation methods, chemical instruments and methods, soil conditioning materials, etc., can solve the problems of soda saline-alkali soil without good improvement means, high content of bicarbonate ions, large carbonate ions, etc. , to achieve the effect of obvious improvement effect, low price and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The steel slag obtained after magnetic separation by Anshan Iron and Steel Group Slag Company was used as raw material and passed through a 100-mesh sieve. The contents of its main chemical components are shown in Table 1.

[0043] Table 1 Determination results of the main chemical components of steel slag for testing (%)

[0044] index SiO 2

Al 2 o 3

TFe(Fe 2 o 3 )

CaO MgO steel slag 14.45 3.71 10.21 42.12 6.54

[0045] The preparation method is as follows: according to the composition of steel slag, control the mass ratio of steel slag, water, and concentrated hydrochloric acid (37% mass concentration) to 1:2.4:2.4, stir evenly, react with oxygen at 25-30°C for 7 days, and stir regularly during this period , to promote the full oxidation of the dissolved ferrous ions into ferric iron. After the reaction, all the materials are dried and used as acidified steel slag modifiers. At this time, the Al in the materials is meas...

Embodiment 2

[0055] The acidified steel slag prepared in Example 1 was selected as the improved material. Taking saline-alkali soil in Baicheng area, Jilin Province as the object of improvement, the soil type tested is soda-type saline-alkali soil, and its salinity content and other indicators are shown in Table 4.

[0056] Table 4 Salinity composition and content of the tested soil

[0057]

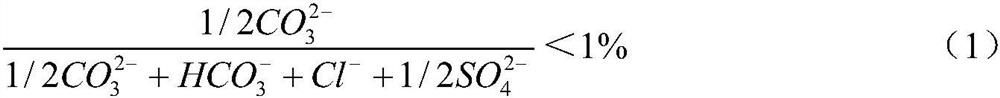

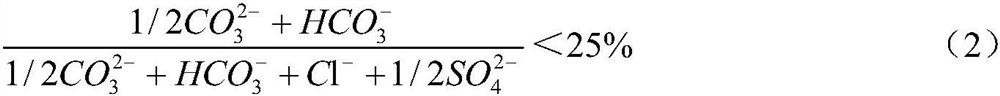

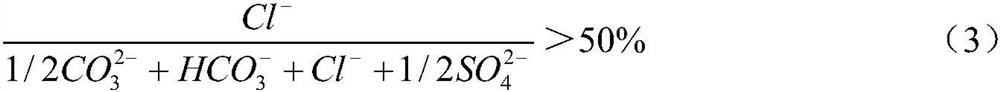

[0058] A total of three plots were set up in the area to be improved, which were respectively the experimental plots of Example 2, Control 1 and Control 2. The area of each plot is 6×5m 2 , the planted crop is rice. Among them, the crest width of the irrigation ditch is 0.8m, and the depth is 0.6m; the crest width of the drainage ditch is 0.7m, and the ditch depth is 1m; the crest width of the ditches is 0.6m, and the height is 0.4m. According to the requirements of formulas (1) to (4), add 36 kg of acidified steel slag, mix the three materials evenly, and apply them to the saline-alkali soil...

Embodiment 3

[0065] The acidified steel slag prepared in Example 1 was selected as the improved material. Taking saline-alkali soil in Jilin area as the object of improvement, the type of soil tested is soda-type saline-alkali soil, and its salinity content and other indicators are shown in Table 6.

[0066] Table 6 Salinity composition and content of the tested soil

[0067]

[0068] A total of three plots were set up in the area to be improved, which were the test plots of Example 3, Control 1 and Control 2, respectively. The area of each plot is 6×5m 2 , the planted crop is rice. Among them, the crest width of the irrigation ditch is 0.8m, and the depth is 0.6m; the crest width of the drainage ditch is 0.7m, and the ditch depth is 1m; the crest width of the ditches is 0.6m, and the height is 0.4m. According to the requirements of formulas (1) to (4), add 40 kg of acidified steel slag, mix the three materials evenly, and apply them to the saline-alkali soil to be improved before ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com