Preparation process of waterproof retro carved gypsum decorative plate

A preparation process and a technology for decorative panels, applied in the direction of coating, etc., can solve the problems of non-degradable plastic material, shortage of wood material resources, unfavorable development of ecological environment and environmental protection, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

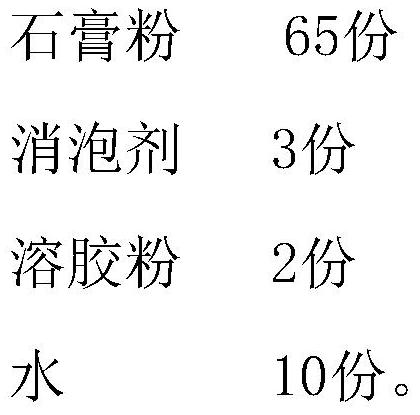

Embodiment 1

[0050] A preparation process for a waterproof retro carved gypsum decorative board, comprising the following steps:

[0051] A, take a shaped gypsum, engrave graphics and texts on the surface of the shaped gypsum, and make a carved gypsum;

[0052] B, the engraving gypsum surface that step A makes is coated with waterproof vintage paint, solidifies, and makes waterproof antique engraving gypsum decorative board;

[0053] The waterproof retro paint comprises 45 parts of polyurethane modified acrylic resin, 5 parts of nano metal powder, 3 parts of curing agent and 20 parts of solvent in parts by weight.

[0054] The nano-metal powder is nano-silver powder; the curing agent is m-xylylenediamine; the solvent is a mixture of ethyl acetate, isopropanol and water in a weight ratio of 2:1:1:.

[0055] In the step B, the coating thickness of the paint is 40 μm; the curing treatment is baked in an oven at a temperature of 50° C. for 60-90 minutes.

[0056] The polyurethane modified ac...

Embodiment 2

[0077] A preparation process for a waterproof retro carved gypsum decorative board, comprising the following steps:

[0078] A, take a shaped gypsum, engrave graphics and texts on the surface of the shaped gypsum, and make a carved gypsum;

[0079] B, the engraving gypsum surface that step A makes is coated with waterproof vintage paint, solidifies, and makes waterproof antique engraving gypsum decorative board;

[0080] The waterproof vintage paint comprises 50 parts of polyurethane modified acrylic resin, 8 parts of nanometer metal powder, 4 parts of curing agent and 25 parts of solvent in parts by weight.

[0081] The nano-metal powder is nano-copper powder; the curing agent is isophorone diamine; the solvent is a mixture of ethyl acetate, isopropanol and water in a weight ratio of 3:1:1.3:.

[0082] In the step B, the coating thickness of the paint is 40 μm; the curing treatment is baked in an oven at a temperature of 50° C. for 60-90 minutes.

[0083] The polyurethane m...

Embodiment 3

[0104] A preparation process for a waterproof retro carved gypsum decorative board, comprising the following steps:

[0105] A, take a shaped gypsum, engrave graphics and texts on the surface of the shaped gypsum, and make a carved gypsum;

[0106] B, the engraving gypsum surface that step A makes is coated with waterproof vintage paint, solidifies, and makes waterproof antique engraving gypsum decorative board;

[0107] The waterproof vintage paint comprises 55 parts of polyurethane modified acrylic resin, 10 parts of nanometer metal powder, 5 parts of curing agent and 30 parts of solvent in parts by weight.

[0108] The nano-metal powder is nano-gold powder; the curing agent is ethylenediamine; the solvent is a mixture of ethyl acetate, isopropanol and water in a weight ratio of 4:1:1.5:.

[0109] In the step B, the coating thickness of the paint is 40 μm; the curing treatment is baked in an oven at a temperature of 50° C. for 60-90 minutes.

[0110] The polyurethane modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com