Bola type surfactant with anion and cation reversal capability and preparation method thereof

A surfactant, anion and cation technology, used in chemical instruments and methods, organic chemistry, transportation and packaging, etc., can solve the problems of backward technology, simple structure, single variety of surfactants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

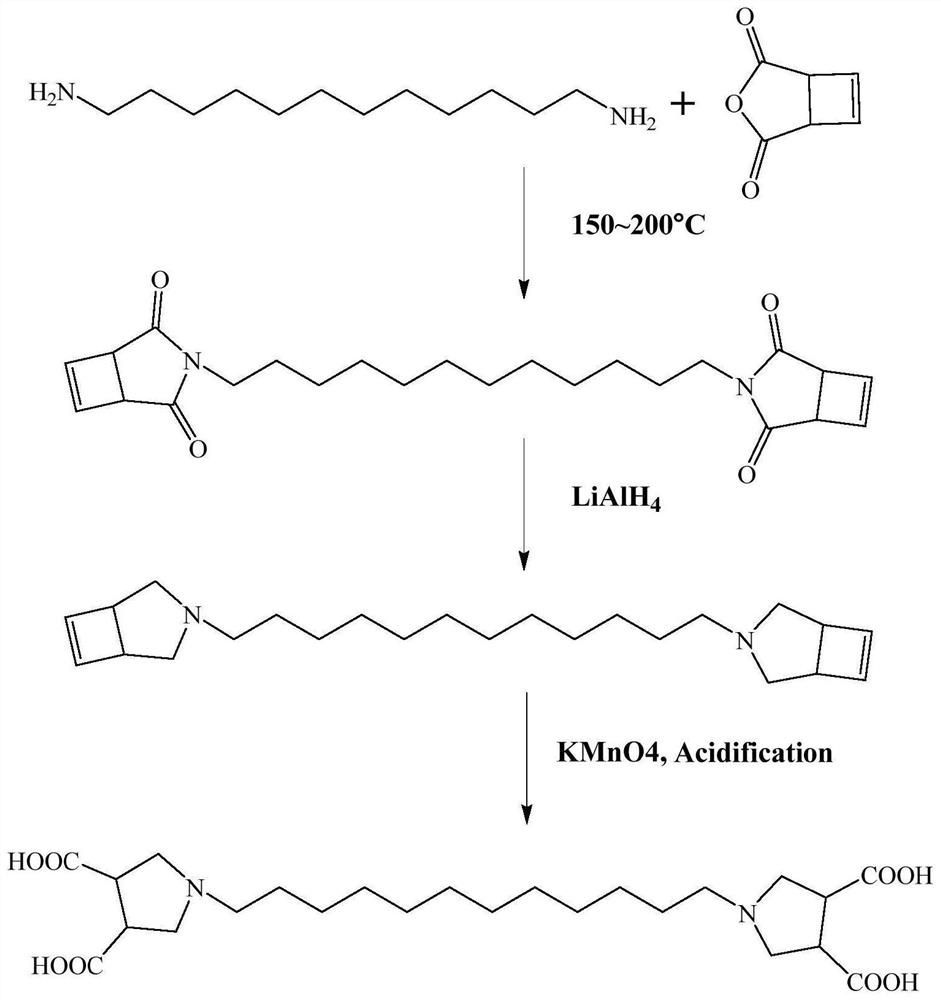

[0037] (1) Add 1,12-diaminododecane (20.0g, 0.1mol) and cyclobut-3-ene dicarboxylic anhydride (49.6g, 0.4mol) dropwise in a 250mL three-necked flask equipped with a reflux condenser , blowing nitrogen three times, and then heated to 180° C. for 3 h, and TLC (Thin Layer Chromatography, thin layer chromatography) monitored the completion of the reaction. After the reaction was completed, it was cooled to room temperature, 50 mL of distilled water was added, extracted three times with 80 mL of ethyl acetate, dried over anhydrous magnesium sulfate, filtered, concentrated under reduced pressure to obtain a crude product, and finally separated by a column to obtain a colorless oily imide.

[0038] (2) Add 80 mL of tetrahydrofuran dried with sodium metal into a 250 mL three-necked flask, cool to 0°C in an ice-salt bath, and slowly add 7.6 g of LiAlH 4 After stirring for 3 minutes, the imide dissolved in tetrahydrofuran was slowly added dropwise into the three-necked flask, and after ...

Embodiment 2

[0042] (1) Add 1,12-diaminododecane (20.0g, 0.1mol) and cyclobut-3-ene dicarboxylic anhydride (49.6g, 0.4mol) dropwise in a 250mL three-necked flask equipped with a reflux condenser , blowing nitrogen for 3 times, and then heated to 150° C. for 2 h, and TLC (Thin Layer Chromatography, thin layer chromatography) monitored the completion of the reaction. After the reaction was completed, it was cooled to room temperature, 50 mL of distilled water was added, extracted three times with 80 mL of ethyl acetate, dried over anhydrous magnesium sulfate, filtered, concentrated under reduced pressure to obtain a crude product, and finally separated by a column to obtain a colorless oily imide.

[0043] (2) Add 90 mL of tetrahydrofuran dried with sodium metal into a 250 mL three-necked flask, cool to 0°C in an ice-salt bath, and slowly add 8.36 g of LiAlH 4 After stirring for 3 minutes, the imide dissolved in tetrahydrofuran was slowly added dropwise into the three-necked flask, and after...

Embodiment 3

[0047] (1) Add 1,12-diaminododecane (20.0g, 0.1mol) and cyclobut-3-ene dicarboxylic anhydride (49.6g, 0.4mol) dropwise in a 250mL three-necked flask equipped with a reflux condenser , blowing nitrogen three times, and then heated to 200° C. for 5 h, and TLC (Thin Layer Chromatography, thin layer chromatography) monitored the completion of the reaction. After the reaction was completed, it was cooled to room temperature, 50 mL of distilled water was added, extracted three times with 80 mL of ethyl acetate, dried over anhydrous magnesium sulfate, filtered, concentrated under reduced pressure to obtain a crude product, and finally separated by a column to obtain a colorless oily imine.

[0048] (2) Add 100 mL of tetrahydrofuran dried with sodium metal into a 250 mL three-necked flask, cool to 0°C in an ice-salt bath, and slowly add 9.12 g of LiAlH 4 After stirring for 3 minutes, the imide dissolved in tetrahydrofuran was slowly added dropwise into the three-necked flask, and afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com