Air-cooled non-active steel slag gypsum-based self-leveling mortar and preparation method thereof

A self-leveling mortar and non-active technology, which is applied in the field of preparation of gypsum-based self-leveling mortar, can solve the problems of low compressive strength of self-leveling mortar, cannot be used in high-strength occasions, insufficient heat preservation and energy saving, and achieves a simple and convenient preparation method , Solve the effect of easy empty drum cracking and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

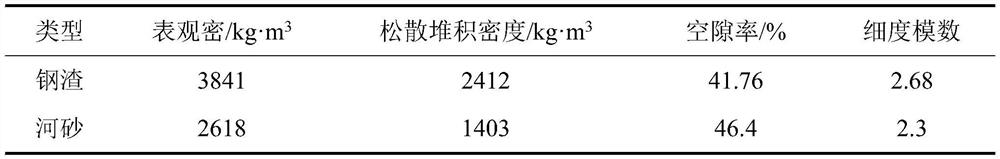

[0033] An air-cooled inactive steel slag gypsum-based self-leveling mortar, comprising the following components by weight:

[0034] 490 parts of β-hemihydrate gypsum powder, 310 parts of steel slag (particle size 0.8mm~1.25mm, anhydrous, bulk density 2412.8g / L), 67 parts of Portland cement (PⅡ52.5), 47 parts of fly ash , 20 parts of metakaolin, 66 parts of heavy calcium, 7 parts of VAE redispersible latex powder, 4 parts of defoamer, 16 parts of water glass (mass concentration is 35%, modulus is 1.3), ZJ-G18 gypsum retarder 0.84 parts, 0.7 parts of polycarboxylate high-performance water reducer (ZJ-8300 type), 269 parts of water.

[0035] Preparation method of air-cooled inactive steel slag gypsum-based self-leveling mortar:

[0036]β-hemihydrate gypsum powder, Portland cement, fly ash, metakaolin, heavy calcium, VAE redispersible latex powder, defoamer, water glass, ZJ-G18 gypsum retarder, polycarboxylic acid high performance Put the water reducing agent into the mortar mix...

Embodiment 2

[0038] An air-cooled inactive steel slag gypsum-based self-leveling mortar, comprising the following components by weight:

[0039] 510 parts of β-hemihydrate gypsum powder, 290 parts of steel slag (particle size 0.8mm~1.25mm, anhydrous, bulk density 2412.8g / L), 83 parts of Portland cement (PⅡ52.5), 40 parts of fly ash , 18 parts of metakaolin, 58 parts of heavy calcium, 7 parts of VAE redispersible latex powder, 4 parts of defoamer, 15 parts of water glass (mass concentration is 35%, modulus is 1.3), ZJ-G18 gypsum retarder 0.84 parts, 0.7 parts of polycarboxylate high-performance water reducer (ZJ-8300 type), 276 parts of water.

[0040] Preparation method of air-cooled inactive steel slag gypsum-based self-leveling mortar:

[0041] β-hemihydrate gypsum powder, Portland cement, fly ash, metakaolin, heavy calcium, VAE redispersible latex powder, defoamer, water glass, ZJ-G18 gypsum retarder, polycarboxylic acid high performance Put the water reducing agent into the mortar mi...

Embodiment 3

[0043] An air-cooled inactive steel slag gypsum-based self-leveling mortar, comprising the following components by weight:

[0044] 500 parts of α-hemihydrate gypsum powder, 300 parts of steel slag (particle size 0.8mm~1.25mm, anhydrous, bulk density 2412.8g / L), 75 parts of Portland cement (PⅡ52.5), 52 parts of fly ash , 30 parts of metakaolin, 50 parts of heavy calcium, 7 parts of VAE redispersible latex powder, 4 parts of defoamer, 18 parts of water glass (mass concentration is 35%, modulus is 1.3), ZJ-G18 gypsum retarder 0.84 parts, 0.7 parts of polycarboxylate high-performance water reducer (ZJ-8300 type), 270 parts of water.

[0045] Preparation method of steel slag gypsum self-leveling mortar:

[0046] α-hemihydrate gypsum powder, Portland cement, fly ash, metakaolin, heavy calcium, VAE redispersible latex powder, defoamer, water glass, ZJ-G18 gypsum retarder, polycarboxylic acid high performance Put the water reducing agent into the mortar mixer, mix and stir for 2 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com