Method and device for manufacturing high-pressure plasticizing wood.

A technology of plasticizing wood and high pressure, applied in wood treatment, pressure impregnation, impregnated wood, etc., can solve problems affecting use, deformation, deterioration, etc., and achieve strong decoration, extended service life, and enhanced strength and compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

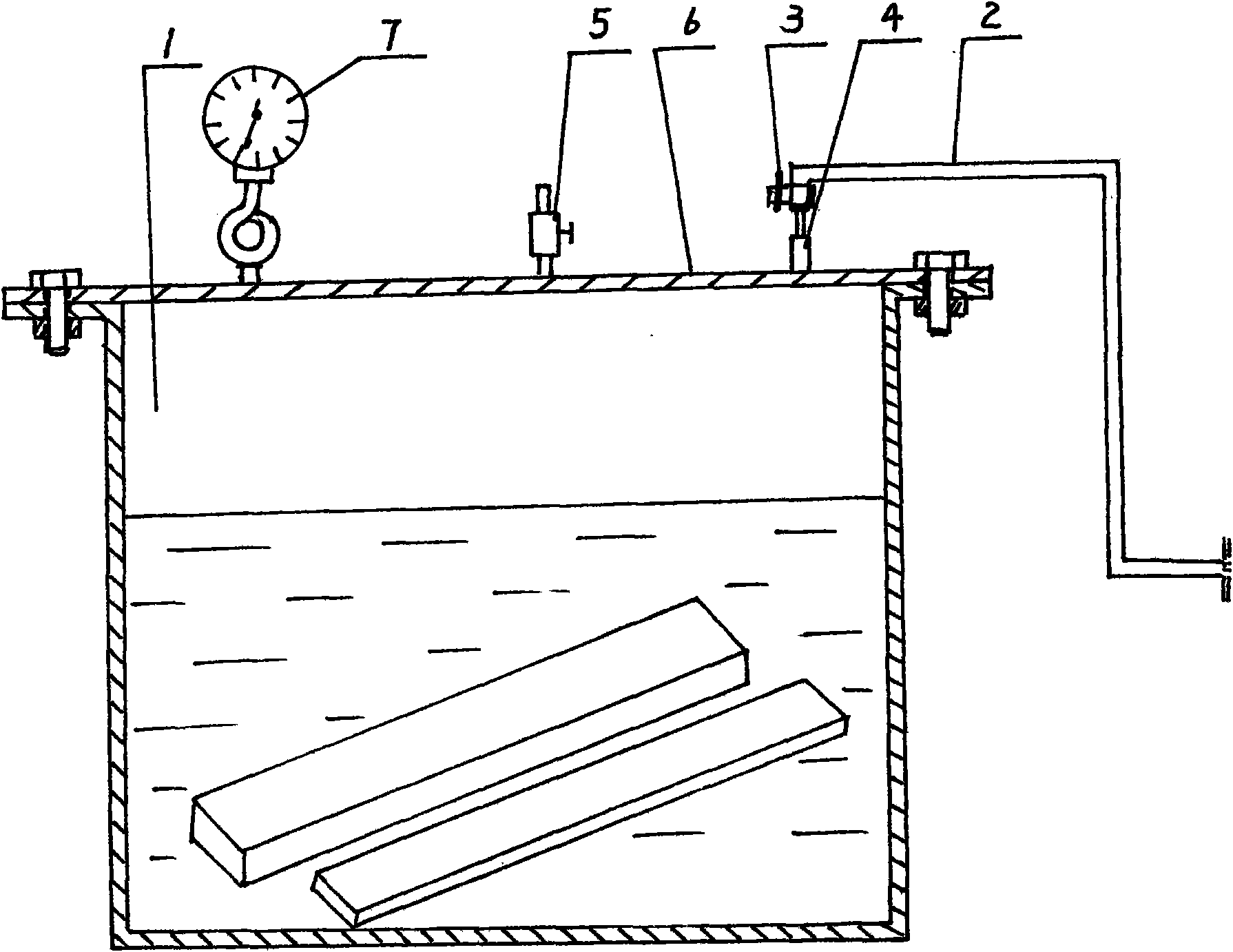

[0015] The method and equipment for preparing high-pressure plasticized wood of the present invention are realized in this way, which will be described in detail below in conjunction with the accompanying drawings. See figure 1 , the equipment for preparing high-pressure plasticized wood is composed of: a high-pressure container 1, a high-pressure inflation pipeline 2, a fixture 3, an inflation nozzle 4, a pressure relief valve 5, a top cover 6 and a pressure gauge 7, and the top cover 6 of the high-pressure container 1 It is equipped with an inflation nozzle 4, a pressure relief valve 5 and a pressure gauge 7. One end of the high-pressure inflation pipeline 2 is fixedly connected with the inflation nozzle 4 with a clamping device 3, and the other end of the high-pressure inflation pipeline 2 is connected with an air compressor or a high-pressure air pump.

[0016] The specific steps of the method for preparing high-pressure plasticized wood are as follows:

[0017] (1) Selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com