A kind of porous charcoal containing three-dimensional amorphous carbon framework and its preparation method and application

A technology of amorphous carbon and frame, applied in the direction of carbon preparation/purification, etc., can solve problems such as unsatisfactory absorbing effect, and achieve the effect of excellent absorbing performance, moderate conductivity, and effective absorption frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

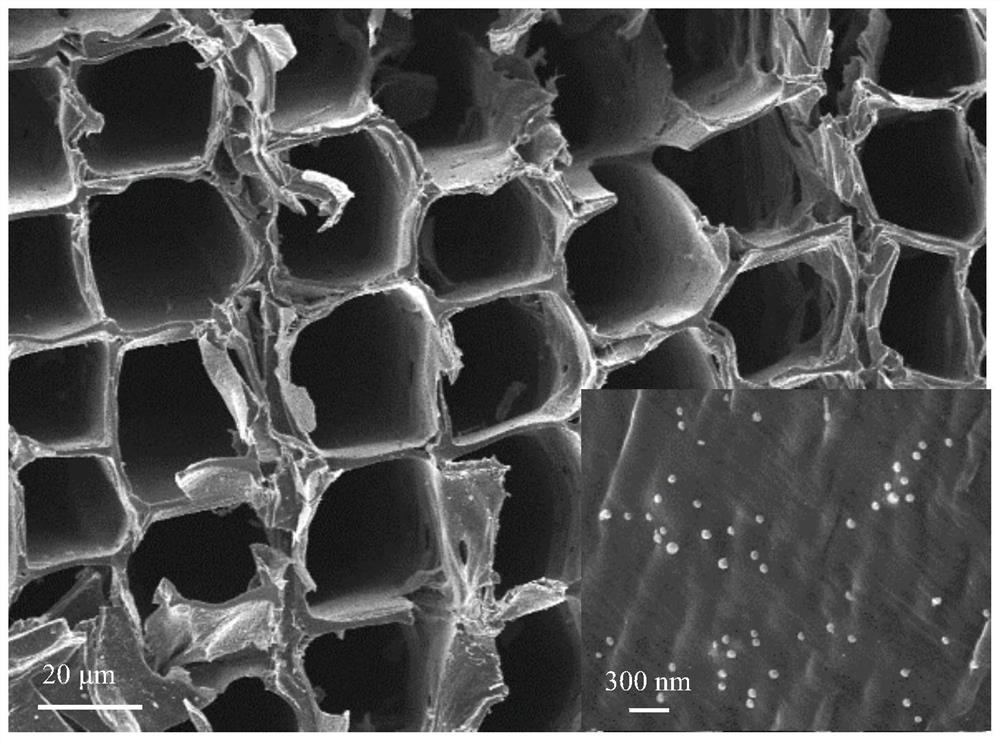

[0033] like figure 1 As shown, a preparation method of porous charcoal containing three-dimensional amorphous carbon framework includes the following steps:

[0034] S1. Pretreatment: Saw the native wood (take masson pine as an example, air-dried or absolutely dry) into 10mm thick wood blocks, put the wood blocks into 500mL of acid sodium chlorite solution with a mass fraction of 2%, Treated at a temperature of 60-75°C for 6-7 hours, some components in the wood block are dissolved out, the micro-nano pore structure of the wood block is enriched, and a porous wood block is formed; wherein, the pH of the solution is 2, and the ratio of wood block mass to solution volume is 3g: 50mL;

[0035] S2. Stabilize the pore structure: Wash the porous wood block with deionized water several times to remove the residual chemicals; then freeze-dry it at -50°C for 50h;

[0036] S3. Formation of amorphous carbon: Put the porous wood block after drying in step S2 into a tube furnace filled wi...

Embodiment 2

[0042] A preparation method of porous charcoal containing three-dimensional amorphous carbon framework, comprising the following steps:

[0043] S1. Pretreatment: Saw the native wood (air-dried or absolutely dry) into wood blocks with a thickness of 7mm, put the wood blocks in 500mL of an acidic sodium chlorite solution with a mass fraction of 5%, at 80-90 ℃ After treatment for 5-7 hours, some components in the wood blocks are dissolved out, and the micro-nano pore structure of the wood blocks is enriched to form porous wood blocks; wherein, the pH value of the solution is 4, and the ratio of the mass of the wood blocks to the volume of the solution is 1 g: 50 mL;

[0044] S2. Stabilize the pore structure: wash the porous wood block with deionized water several times to remove the residual chemicals in the porous wood block; then freeze-dry it at -80°C for 48 hours;

[0045] S3. Formation of amorphous carbon: put the porous wood block after drying in step S2 into an oven, heat...

Embodiment 3

[0047] A preparation method of porous charcoal containing three-dimensional amorphous carbon framework, comprising the following steps:

[0048] S1. Pretreatment: Saw the native wood (air-dried or absolutely dry) into wood blocks with a thickness of 5mm, put the wood blocks in 500mL of an acidic sodium chlorite solution with a mass fraction of 3%, and treat them at 100 ° C for 5 -7h, some components in the wood block are dissolved out, the micro-nano pore structure of the wood block is enriched, and a porous wood block is formed; wherein, the pH value of the solution is 3, and the ratio of the mass of the wood block to the volume of the solution is 2g:50mL;

[0049] S2. Stabilize the pore structure: Wash the porous wood block with deionized water several times to remove the residual chemicals in the porous wood block; then freeze-dry it at -50°C for 48h;

[0050] S3. Formation of amorphous carbon: put the porous wood block treated and dried in step S2 into an oven, first heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com