Preparation method of manganese phosphate

A technology of manganese phosphate and concentrated phosphoric acid, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as complex reaction system, long reaction time, and introduction of sulfate radicals, and achieve simple process, low cost, and simple reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

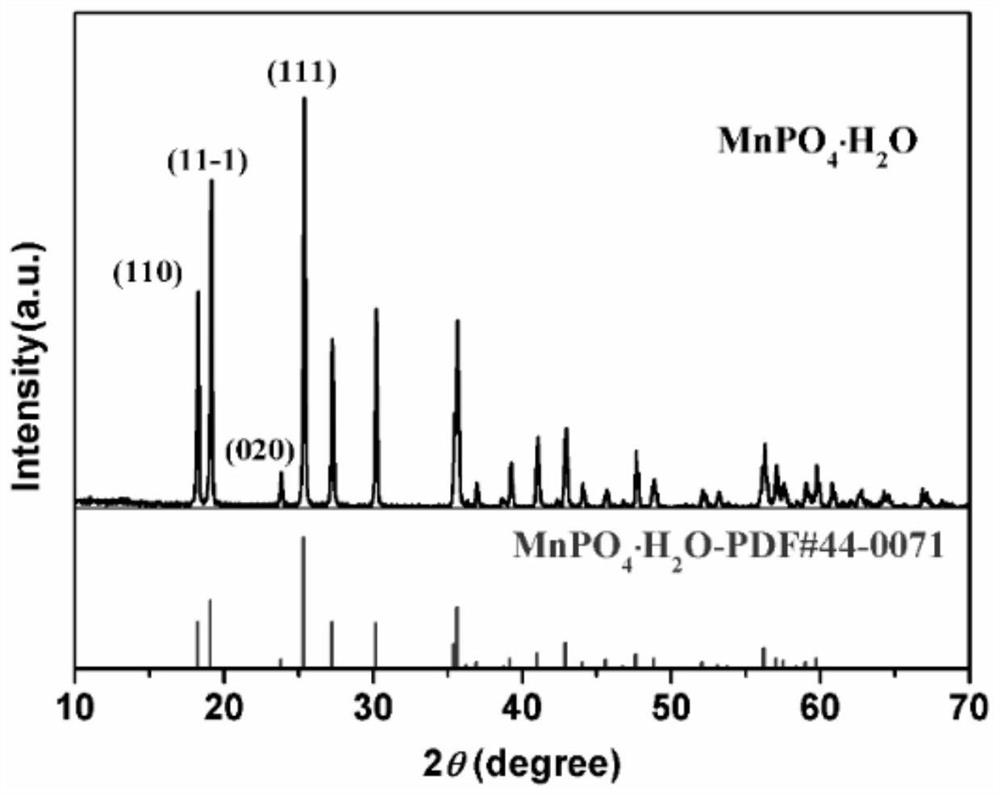

[0019] Weigh 4g of potassium permanganate, measure 20mL of phosphoric acid with a mass fraction of 85wt%, add it into a 50mL reaction kettle and stir evenly. After the reaction kettle is sealed, put it in an oven and react at 180°C for 12 hours. After cooling, filter, wash and dry the slurry to obtain gray-green manganese phosphate MnPO 4 ·H 2 O powder, manganese phosphate yield is ~ 99%. Carry out XRD detection to the manganese phosphate prepared, its result is as follows figure 1 shown. From figure 1 It can be seen that the manganese phosphate obtained in this example is pure phase manganese phosphate monohydrate.

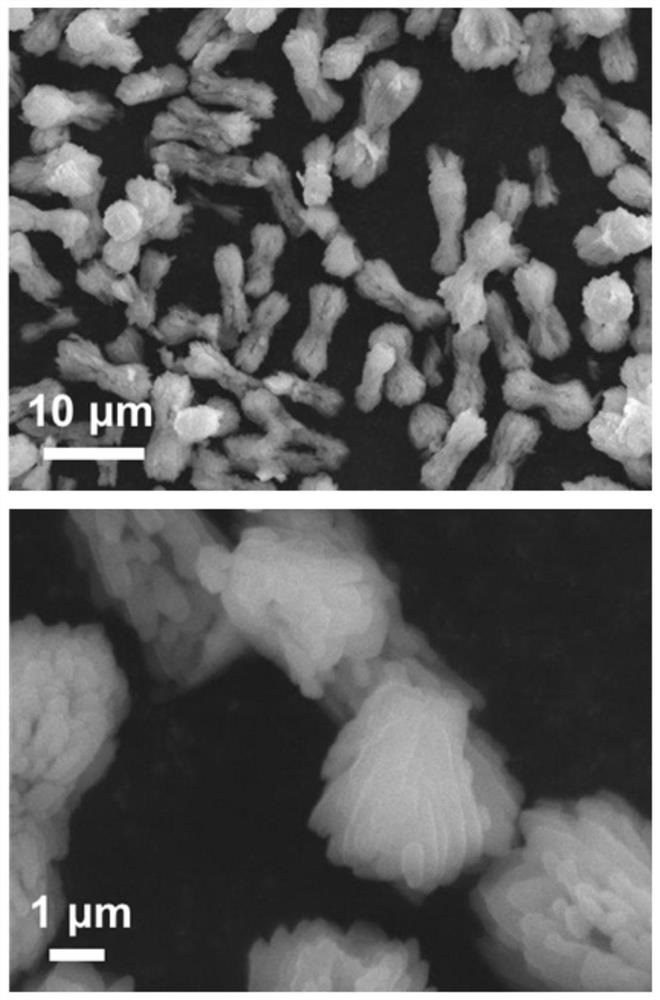

[0020] Carry out SEM detection to the manganese phosphate prepared by the present embodiment, the result is as follows figure 2 shown. Depend on figure 2 It can be seen that the particle size distribution of the manganese phosphate prepared in this example is uniform, and its secondary particles are dumbbell-shaped.

Embodiment 2

[0022] Weigh 3g of potassium permanganate, measure 20mL of phosphoric acid with a mass fraction of 85wt%, add it into a 100mL four-neck flask and stir evenly. Heat the oil bath to 150°C and react for 6 hours. After cooling, filter, wash and dry the slurry to obtain gray-green manganese phosphate MnPO 4 ·H 2 O powder, manganese phosphate yield is ~ 99%.

Embodiment 3

[0030] Weigh 4g of potassium permanganate, measure 40mL of phosphoric acid with a mass fraction of 85wt%, add to a 50mL reaction kettle and stir evenly. After the reaction kettle is sealed, put it into an oven and react at 140°C for 14 hours. After cooling, filter, wash and dry the slurry to obtain gray-green manganese phosphate MnPO 4 ·H 2 O powder, manganese phosphate yield is ~ 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com