Bearing protection paper pad for transmission shaft production

A technology for drive shafts and paper pads, which is applied in the direction of preventing mechanical damage to containers, containers, packaging, etc. It can solve the problems that multiple fixing structures cannot be fixed together, and oil pollution cannot be intercepted and small parts are prevented from rolling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

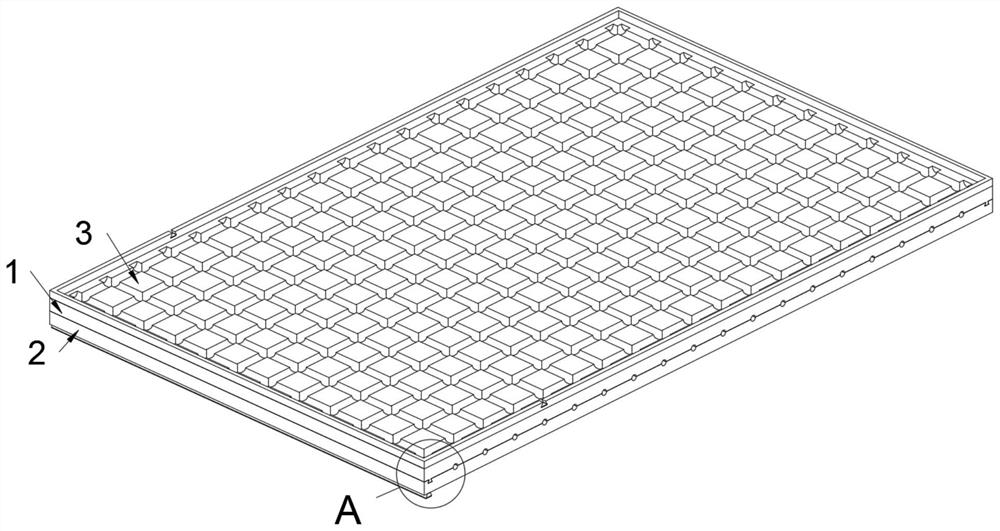

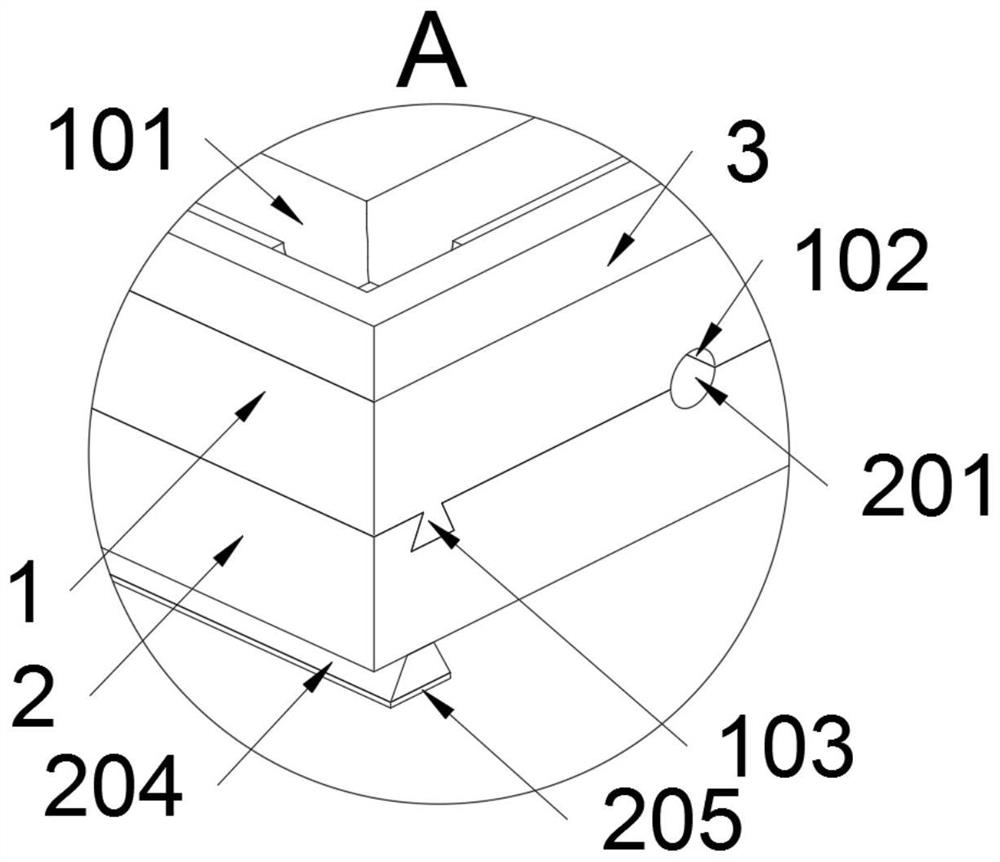

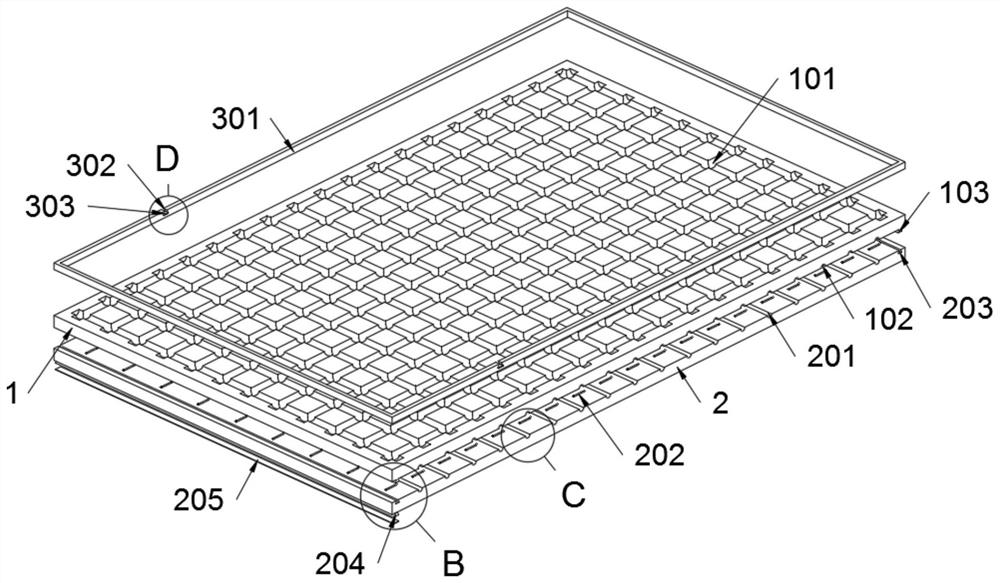

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036]The present invention provides a protective paper pad used for transmission shaft production, including a top pad 1; a bottom pad 2 is adhered to the bottom surface of the top pad 1, and a protective structure 3 is welded to the top surface of the top pad 1; refer to image 3 with Image 6 , the bottom pad 2 includes a locking protrusion B204, a locking protrusion B204 is welded to the bottom surface of the bottom pad 2, and the locking protrusion B204 is a trapezoidal block structure; the protective structure 3 includes a frame body 301 and a locking groove 302, The frame body 301 is welded on the top surface of the top pad 1, and the frame body 301 is a rectangular frame structure; the top surface of the frame body 301 is symmetrically provided with two clamping grooves 302, and the two clamping grooves 302 are trapezoidal groove-shaped structures ; The clamping groove 302 is clamped and connected with the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com