A kind of arrangement method of light truck three pedals

A layout method and a technology of pedals, which are applied to the layout of power plant control mechanisms, control devices, foot-operated starting devices, etc., can solve problems such as high development costs and long development cycles, and achieve reduced development costs, reasonable settings, and improved comfort degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

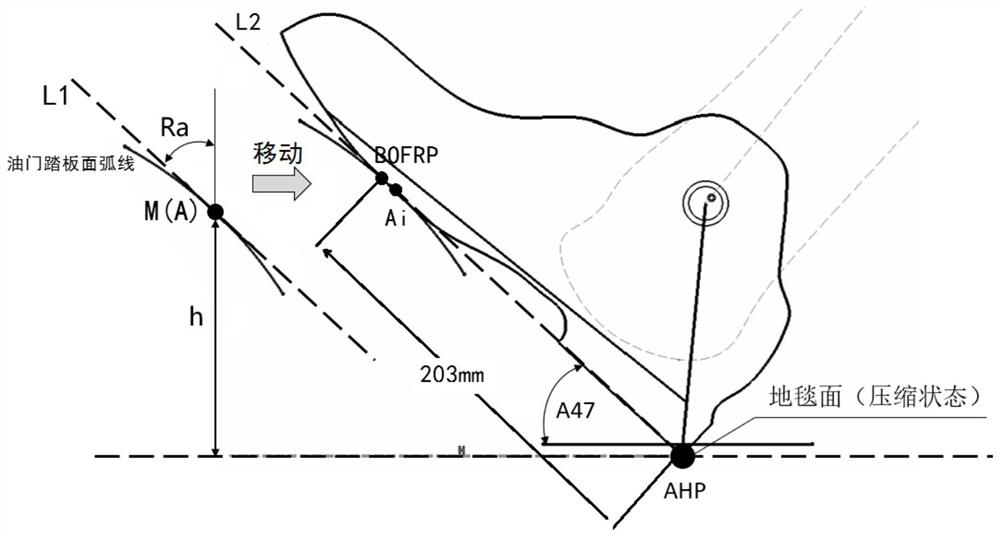

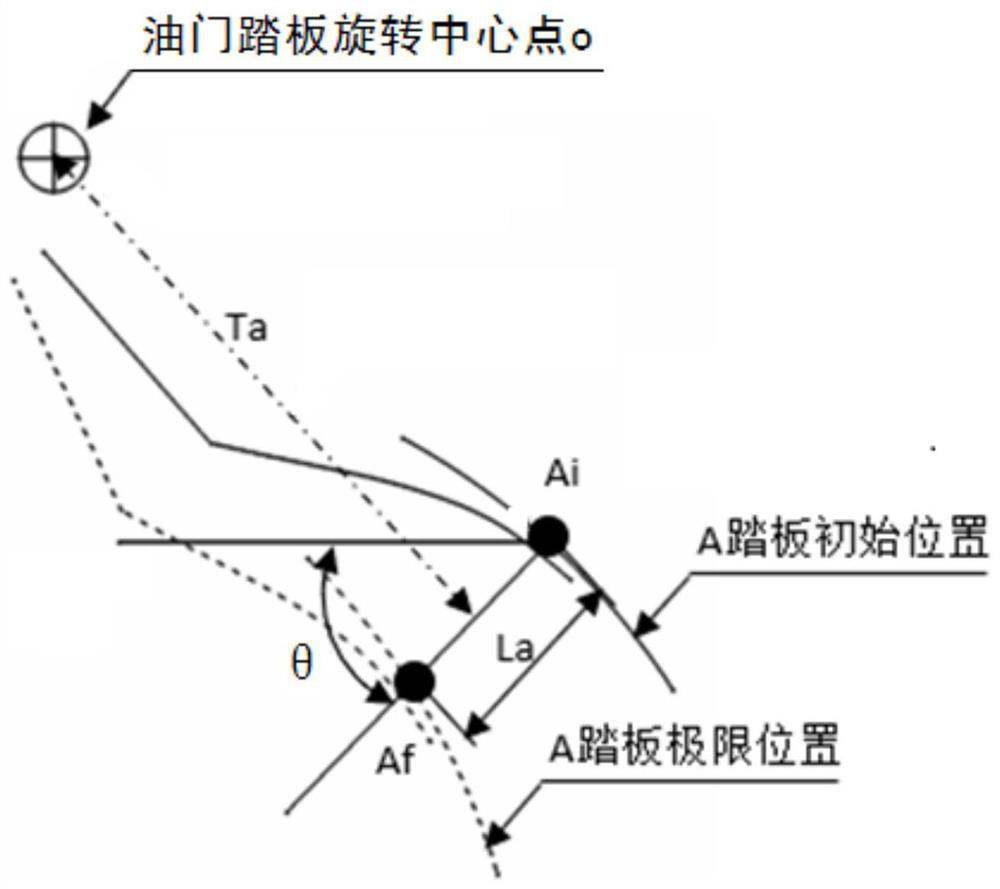

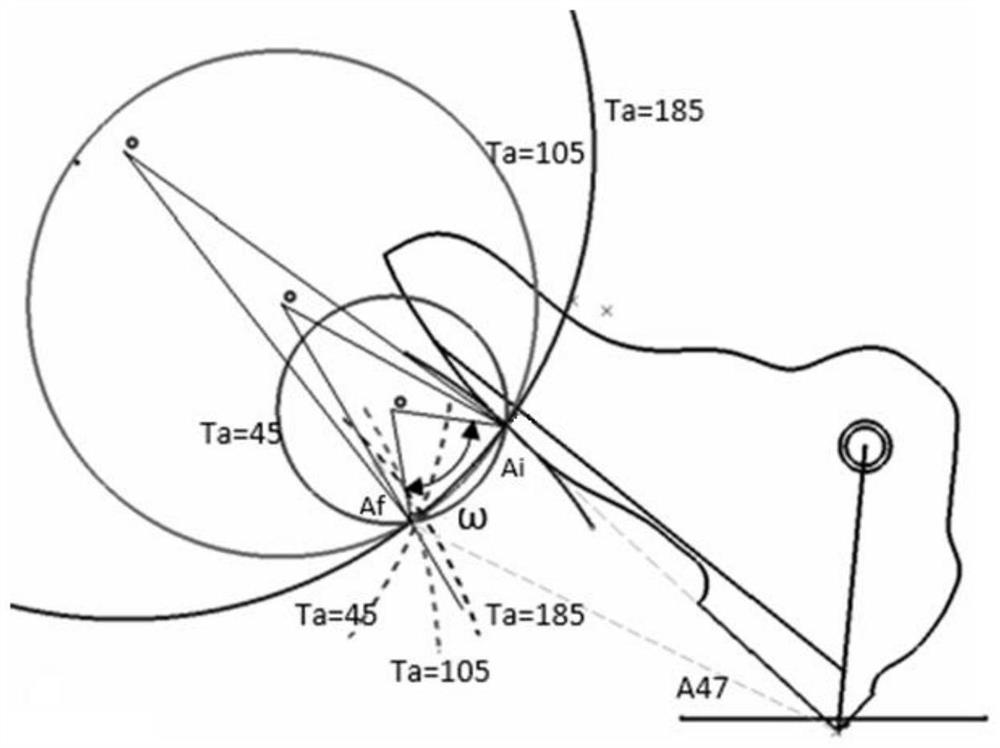

[0147] A method for arranging three pedals of a light truck, the method of arranging the three pedals is based on the following conditions: the method for arranging the three pedals of the light truck is the design of a suspended three-pedal; the seat height H30 and the span of the vehicle to be designed are known. H. Heel point AHP, the shape and size of the suspended accelerator pedal, the shape and size of the suspended brake pedal, the shape and size of the suspended clutch pedal, and the carpet plane in the compressed state, including the following steps:

[0148] Step 1. Preliminarily calculate the estimated pedal height h of the accelerator pedal according to H30:

[0149] h=-0.0005(H30) 2 +0.2025(H30)+138 Formula (1);

[0150] The pedal height h of the accelerator pedal can take a value within the range of the calculation result ± 10mm;

[0151] Step 2. Preliminarily calculate the estimated pedal angle Ra of the accelerator pedal according to H30:

[0152] Ra=0.0008...

Embodiment 2

[0188] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0189] The three-pedal arrangement method of the light truck also includes comprehensively determining the lateral distribution of the accelerator pedal, brake pedal, and clutch pedal:

[0190] After arranging the lateral positions of the accelerator pedal, brake pedal and clutch pedal in step 8, determine whether the lateral positions of the accelerator pedal, brake pedal and clutch pedal meet the following judgment requirements at the same time,

[0191] The lateral span d of the center point C of the clutch pedal is 330 mm to 390 mm;

[0192] The lateral distance e between the brake pedal center point B and point H is 150 mm to 180 mm;

[0193] If the lateral positions of the accelerator pedal, brake pedal, and clutch pedal do not meet the determination requirements, then return to step 8 to adjust the lateral positions of the accelerator pedal, brake pedal, and clutch pedal;

[0194] If t...

Embodiment 3

[0196] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0197] The three-pedal arrangement method of the light truck also includes checking the lateral distribution of the accelerator pedal and the brake pedal and the spatial relationship of the drop distribution:

[0198] After comprehensively determining the lateral distribution of the accelerator pedal, brake pedal and clutch pedal, check the lateral distribution of the accelerator pedal and the brake pedal and the spatial relationship of the normal drop according to the following requirements:

[0199] When 65≤b≤80, 35≤PL3≤-1.67b+173;

[0200] When 50≤b≤65, -0.5b+70≤PL3≤65;

[0201] If the arrangement of the accelerator pedal and brake pedal does not meet the above check requirements, return to step 1 to re-arrange;

[0202] If the arrangement of the accelerator pedal and the brake pedal meets the above verification requirements, proceed to step 9 for verification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com