An ultra-high pressure small hydraulic press system

A hydraulic press and ultra-high pressure technology, applied in the field of ultra-high pressure small hydraulic press systems, can solve problems such as large weight and size, overall system size, large weight, and small pressing load, so as to improve installation efficiency and installation accuracy, overall size and weight The effect of shrinking and reducing the weight of the press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following structural description drawings further describe the specific technical solutions of the present invention.

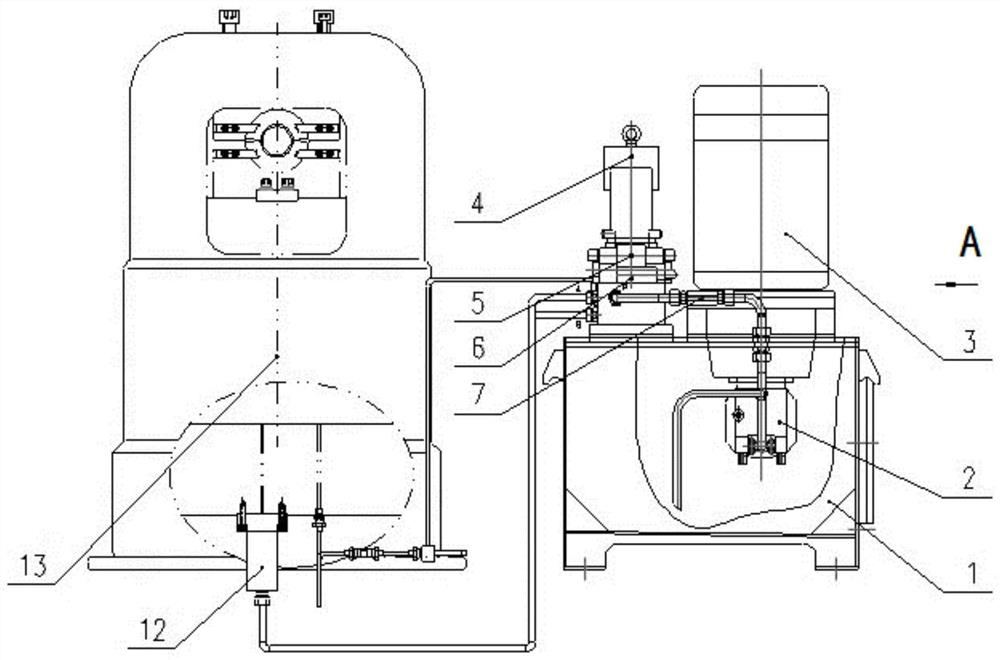

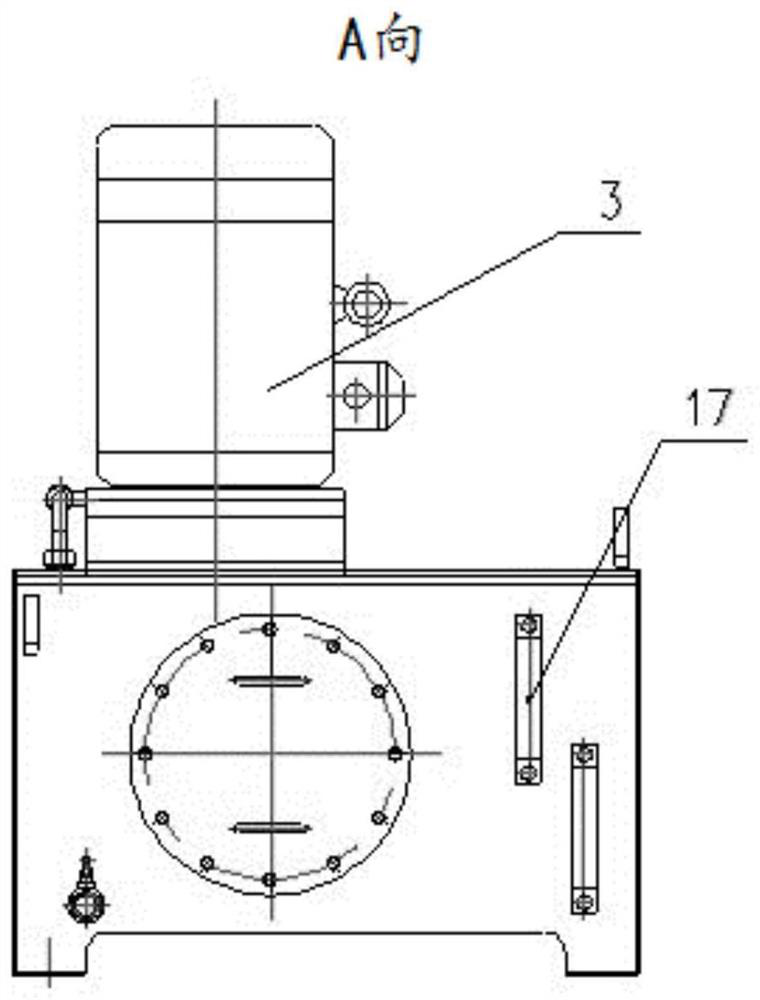

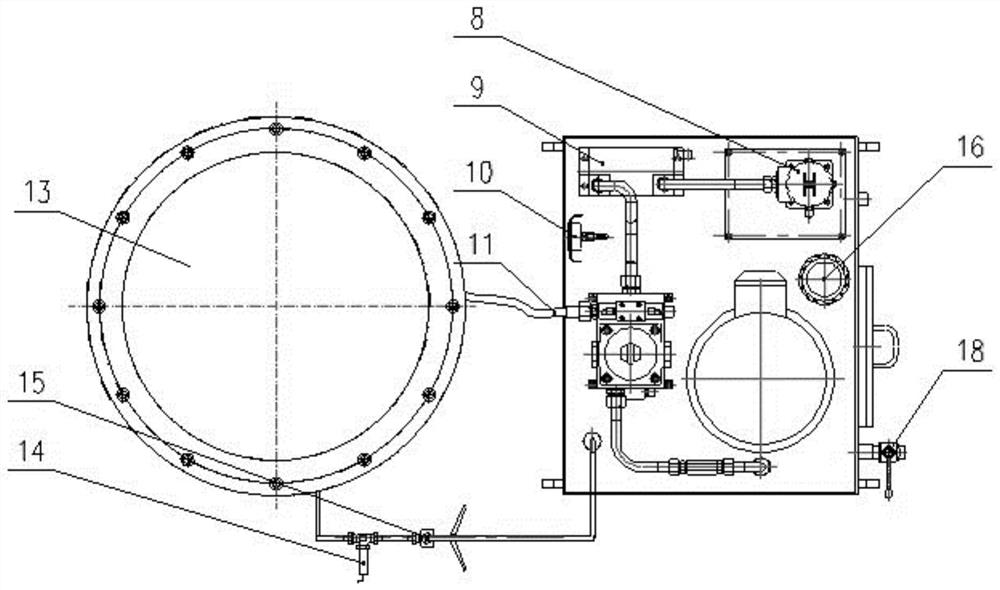

[0040] as attached Figure 1-5 As shown, an ultra-high pressure small hydraulic press system of the present invention mainly includes a fuel tank 1, a hydraulic pump 2, a motor 3, a pressure filter 4, an electromagnetic reversing valve 5, a relief valve 6, a one-way valve 7, and an oil return filter. 8, air cooler 9, pressure gauge 10, hose 11, supercharger 12, oil cylinder 13, pressure sensor 14, manual pressure relief valve 15, air filter 16, liquid level gauge 17, drain valve 18, clock shape cover 19, shock absorber ring 20 and coupling 21.

[0041] The oil tank 1 is welded by stainless steel plate, and the top plate of the oil tank has a flange hole; the motor 3, the bell 19 and the shock absorber ring 20 are connected to the flange hole of the oil tank 1 through bolts; the motor 3 is connected to the hydraulic pump 2 through the coupling 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com