Precast concrete component mold demolding device

A technology of prefabricated components and demolding devices, applied in unloading devices, manufacturing tools, etc., can solve the problems of large fluctuations in the number of impacts, easily damaged molds, poor demolding stability, etc., to ensure synchronization, smooth demolding, Avoid distortion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

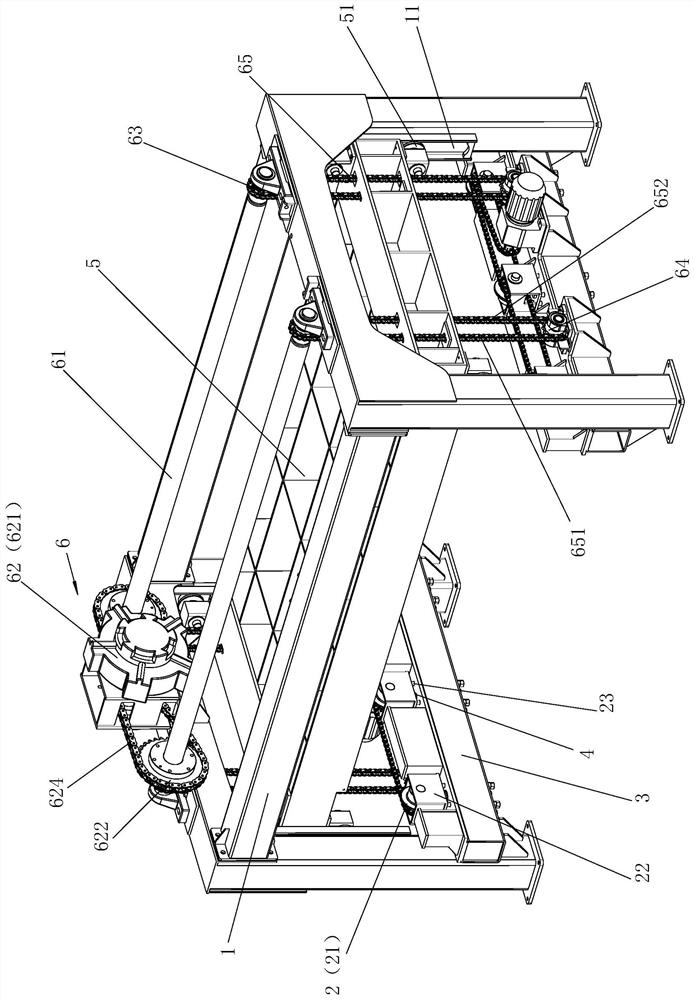

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

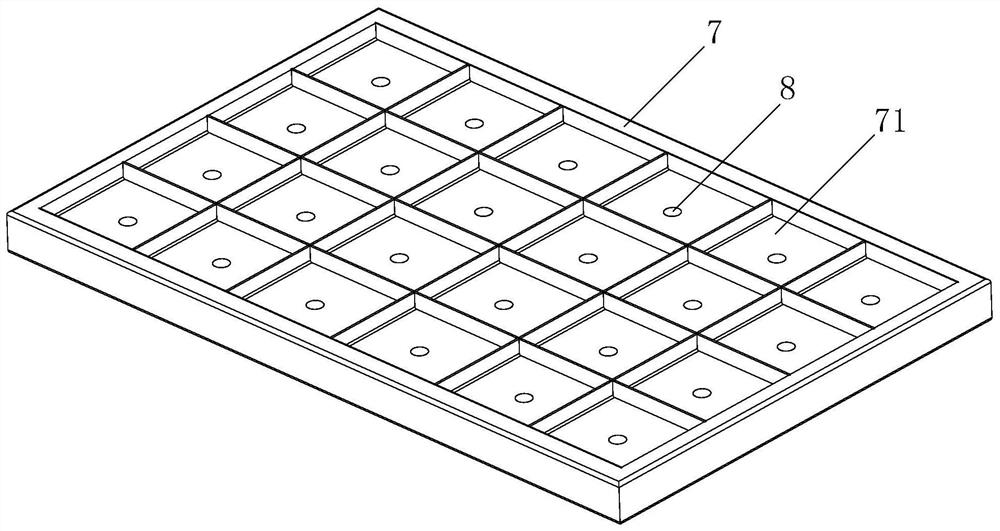

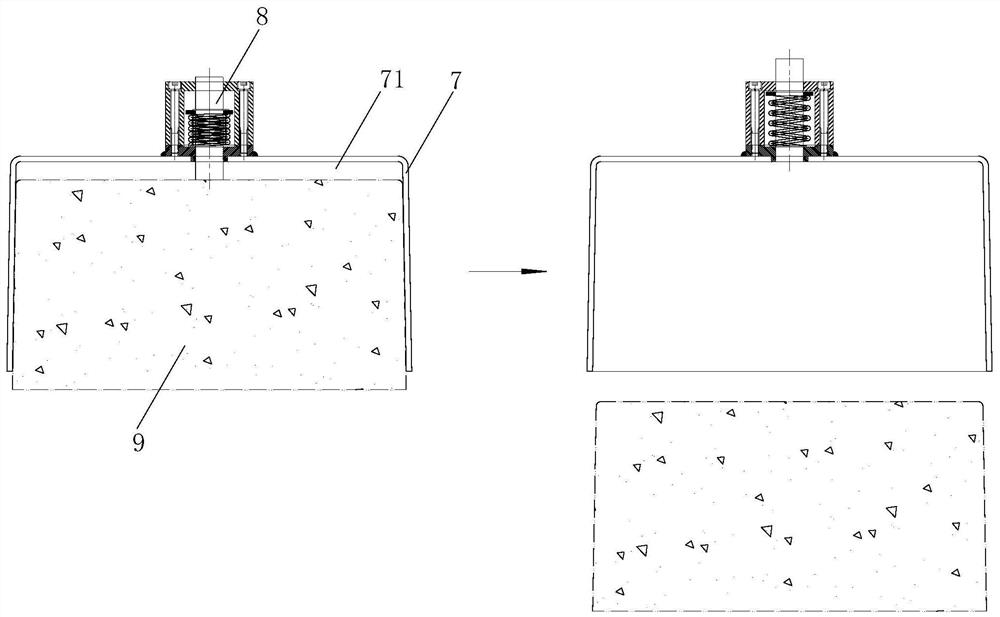

[0020] image 3 Shown is an embodiment of the concrete prefabricated component mold demoulding device of the present invention, the concrete prefabricated component mold demoulding device of the present embodiment comprises a frame 1, and the frame 1 is provided with two rows of mold delivery tracks 2, each mold There is a mold pallet 3 under the conveying track 2, an elastic buffer 4 is set between the mold pallet 3 and the mold conveying track 2, and a demoulding pressing block 5 is arranged above the mold transporting track 2, and the demoulding pressing block 5 is equipped with a lifting drive Institution 6. Wherein, the elastic buffer member 4 can be, for example, a coil spring, a disc spring, elastic rubber, and the like.

[0021] The mold demoulding device for prefabricated concrete components is provided with two rows of mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com