Drill bit for coal mine gas drainage hole

A technology for coal mine gas and extraction holes, which is applied to drill bits, gas discharge, drilling equipment, etc., and can solve problems such as blockage, abnormal protruding of grate, and difficulty of grate protruding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

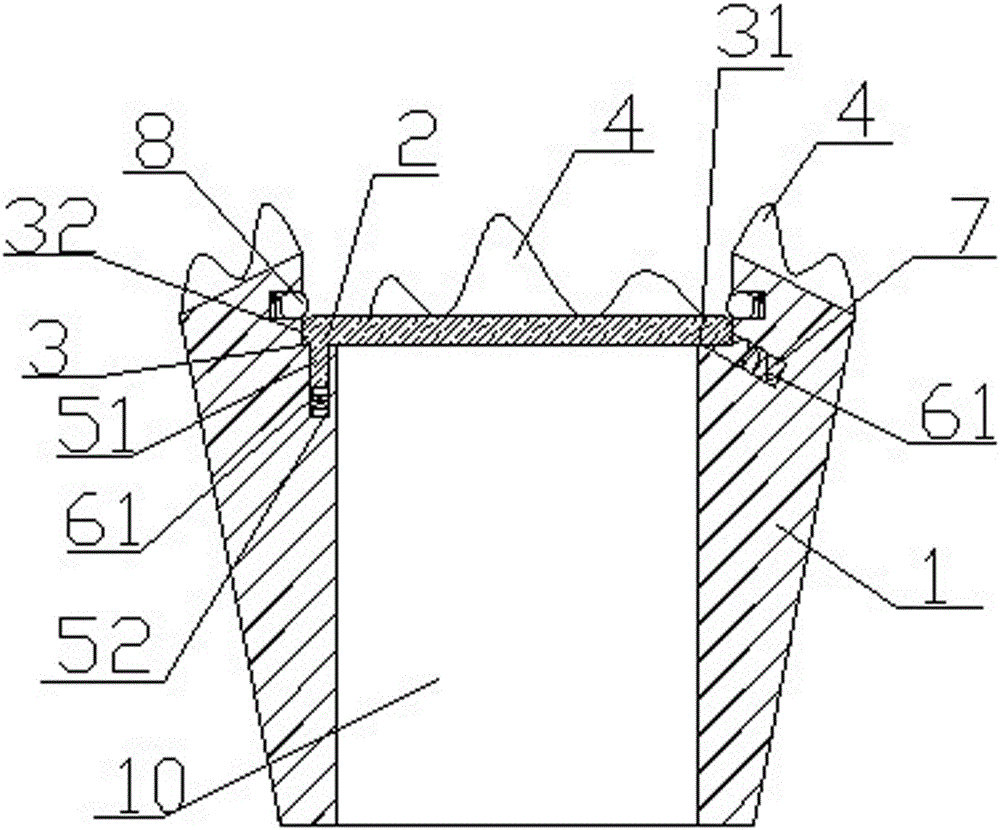

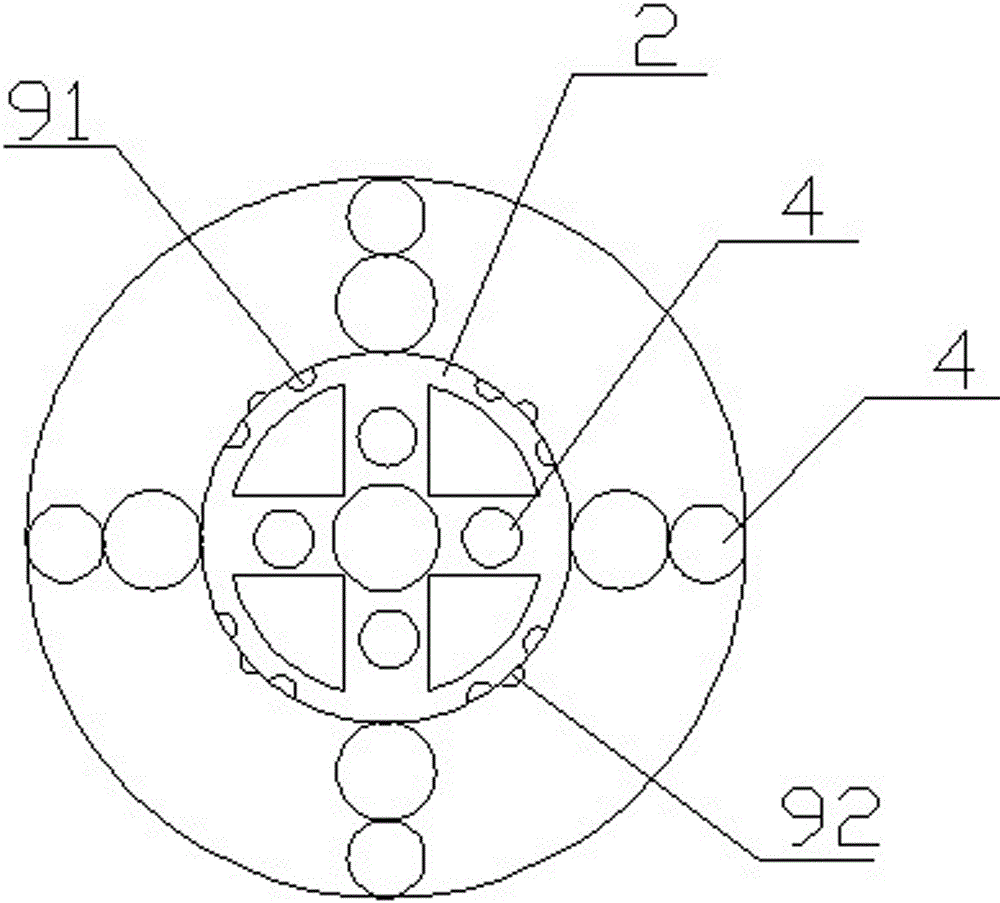

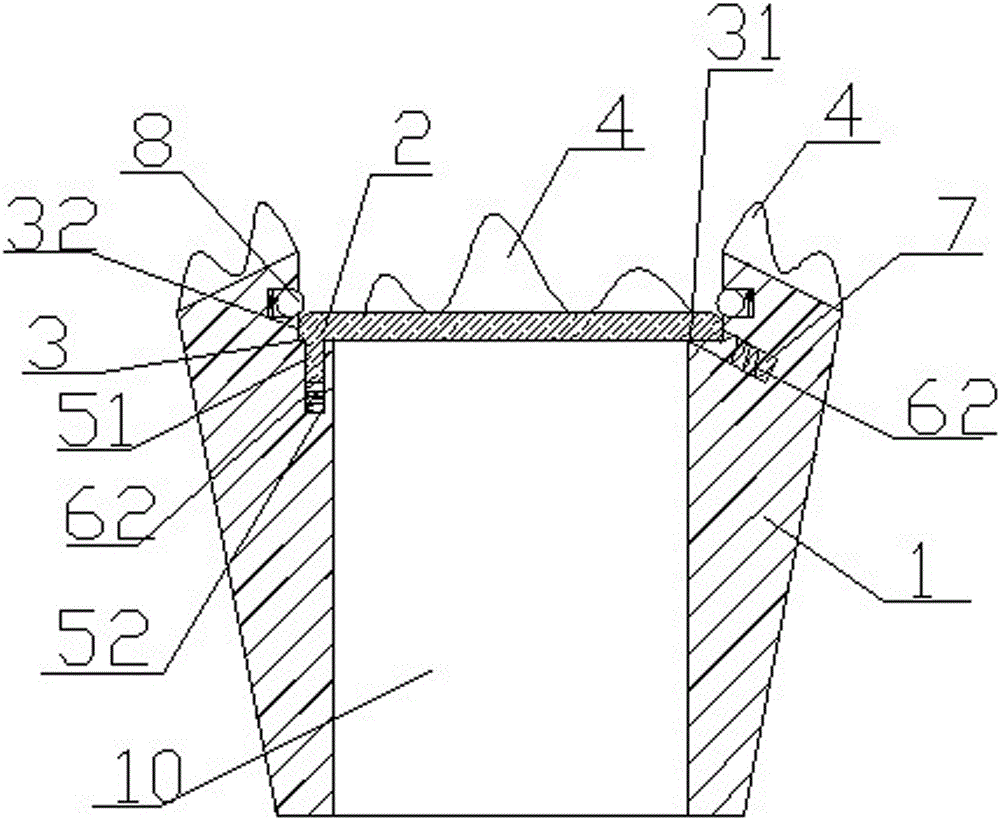

[0038] Such as Figure 4 A coal mine gas drainage hole drill bit, the drill bit is axially provided with a through hole, the top of the through hole is provided with a grate frame 3, the grate frame 3 is provided with a grate 2, and the contact part between the grate frame 3 and the grate 2 is in the shape of a bell mouth 35, Grate 2 cooperates with grate frame 3, and cutter head 4 is established on the grate, and the grate 2 periphery is fixed in the grate frame 3 by touch beads 8. When the gas extraction pipe pushes against the grate and overcomes the elastic force of the touch bead 8, the spline comes out of the grate frame, the grate stays in the hole, the grate frame of the drill bit is covered with the gas extraction pipe and exits, and the gas extraction pipe stays at the bottom of the gas drainage hole , Gas extraction is more thorough.

[0039] The gap fit between the grate frame 3 and the grate 2, the gap is 0.05mm-0.15mm.

[0040] Ventilation slots are set between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com