Precision machining method for geometrical shape of hollow rotating shaft of motor

A hollow shaft and geometric shape technology, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of low accuracy of the geometric shape of the hollow rotation of the motor, cracking of the hollow shaft of the motor, affecting safe production, etc., and achieve convenient Processing, method clarification, effect of improving symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

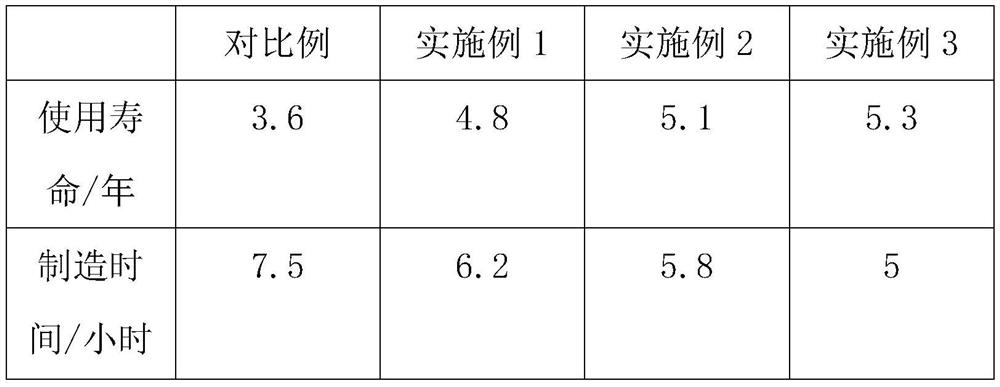

Embodiment 1

[0030] Step 1: Basic treatment of the shaft and equipment: conduct a comprehensive inspection on the surface of the shaft, remove defective products, and thoroughly clean the qualified shaft, then turn on the equipment and enter the standby state;

[0031] Step 2: Selection and processing of auxiliary materials: Select suitable manganese, chromium, nickel and carbon, and conduct a comprehensive inspection of their quality, put the auxiliary materials that pass the inspection into a sealed crucible for heating, and raise the temperature to 1350 degrees Celsius, After the liquid substance is stable, keep it warm for 10 minutes;

[0032] Step 3: High-level treatment of auxiliary materials: Take out the solution in the high-temperature molten state from the sealed furnace, then use external high-temperature resistant equipment to remove floating impurities on the surface of the high-temperature solution, and then put the container back into the sealed furnace to continue heating ,...

Embodiment 2

[0038] Step 1: Basic treatment of the shaft and equipment: conduct a comprehensive inspection on the surface of the shaft, remove defective products, and thoroughly clean the qualified shaft, then turn on the equipment and enter the standby state;

[0039] Step 2: Selection and processing of auxiliary materials: Select suitable manganese, chromium, nickel and carbon, and conduct a comprehensive inspection of their quality, put the auxiliary materials that pass the inspection into a sealed crucible for heating, and raise the temperature to 1400 degrees Celsius, After the liquid substance is stable, keep it warm for 15 minutes;

[0040]Step 3: High-level treatment of auxiliary materials: Take out the solution in the high-temperature molten state from the sealed furnace, then use external high-temperature resistant equipment to remove floating impurities on the surface of the high-temperature solution, and then put the container back into the sealed furnace to continue heating , ...

Embodiment 3

[0046] Step 1: Basic treatment of the shaft and equipment: conduct a comprehensive inspection on the surface of the shaft, remove defective products, and thoroughly clean the qualified shaft, then turn on the equipment and enter the standby state;

[0047] Step 2: Selection and processing of auxiliary materials: Select suitable manganese, chromium, nickel and carbon, and conduct a comprehensive inspection of their quality, put the auxiliary materials that pass the inspection into a sealed crucible for heating, and raise the temperature to 1500 degrees Celsius, After the liquid substance is stable, keep it warm for 20 minutes;

[0048] Step 3: High-level treatment of auxiliary materials: Take out the solution in the high-temperature molten state from the sealed furnace, then use external high-temperature resistant equipment to remove floating impurities on the surface of the high-temperature solution, and then put the container back into the sealed furnace to continue heating ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com