Cryostat assembly having a resilient, heat-conducting connection element

A technology for cryostats and connecting components, applied to electrical components, household appliances, magnetic objects, etc., can solve problems such as unstable uniformity, and achieve good thermal contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

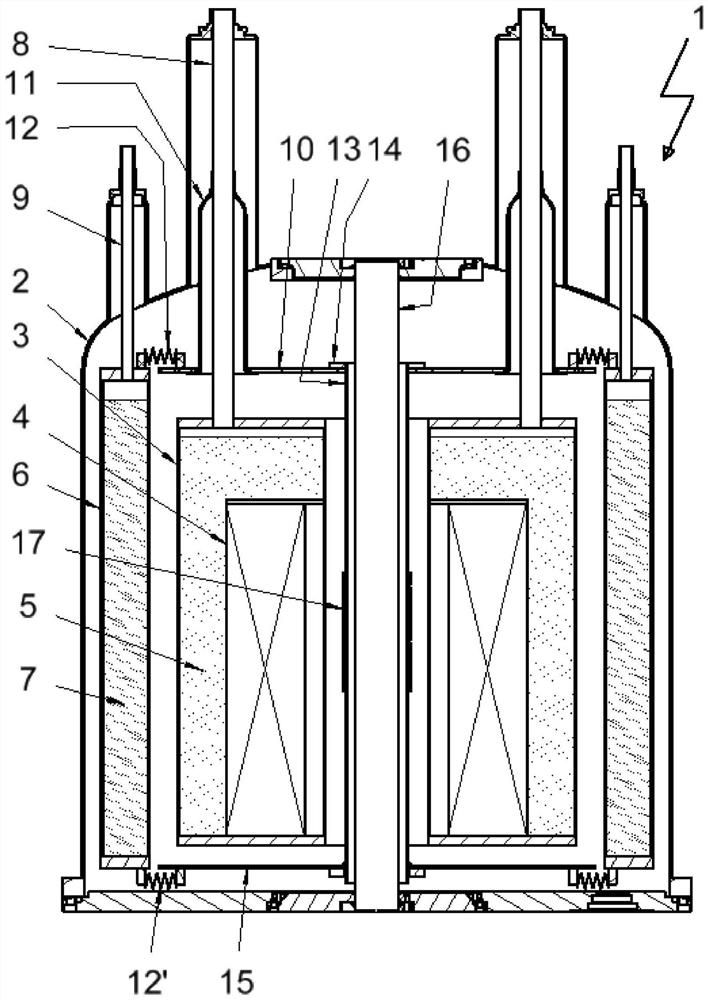

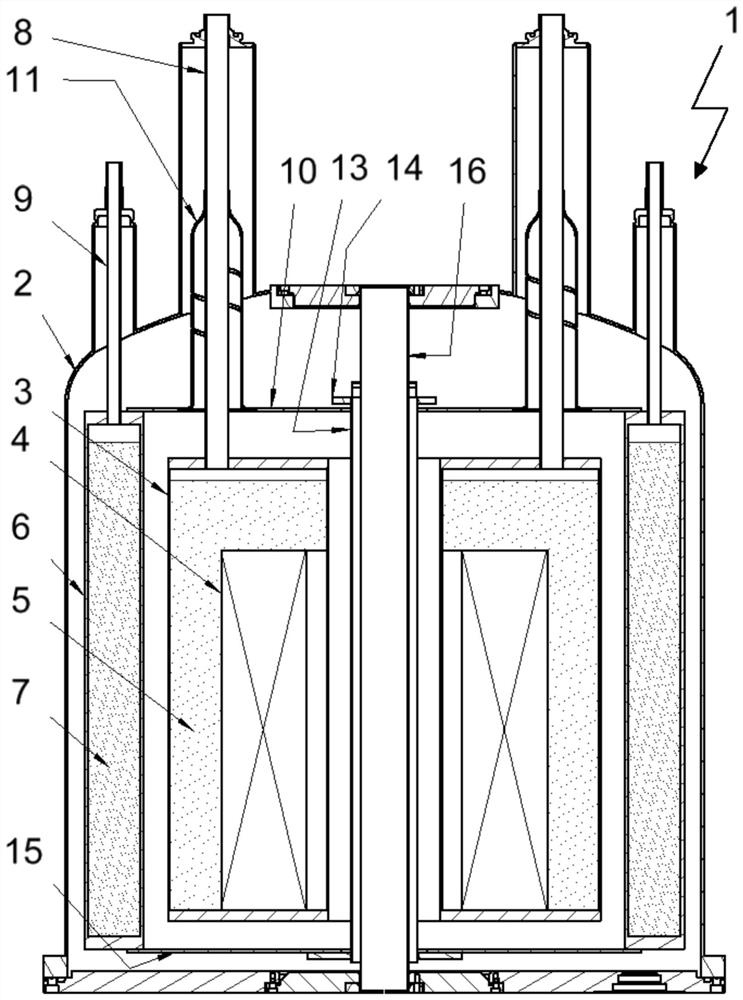

[0056] in the picture figure 1 and 3 6 to 6 each show a preferred embodiment of a cryostat assembly according to the invention for cooling a superconducting magnet assembly in a schematic view in different details, while figure 2 A typical cryostat assembly according to the closest prior art is shown.

[0057] A cryostat assembly 1 of this type has an outer container 2 in which a coil tank 3 with a superconducting magnet coil system 4 to be cooled and a first cryostat fluid 5 is arranged. The superconducting magnet coil system 4 is also cooled, at least in the operating state, by a second cryostat fluid 7 located in the storage tank 6 , which has a higher temperature than the first cryostat fluid 5 . The coil tank 3 is fixed mechanically rigidly to the outer container 2 by means of at least one first suspension element 8 and the storage tank 6 is fixed mechanically rigidly to the outer container 2 by means of at least one second suspension element 9 . Furthermore, the stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com