Measuring device and detection method for stress and strain between sand body particles

A measuring device and strain measuring technology, which is applied in the direction of measuring device, electromagnetic measuring device, electric/magnetic solid deformation measurement, etc., can solve the problems of inability to detect different particle stress and strain, irregular shape of coral sand particles, and coral sand consolidation time Shortening and other issues, to achieve the effect of small force deformation, meet the strain range, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

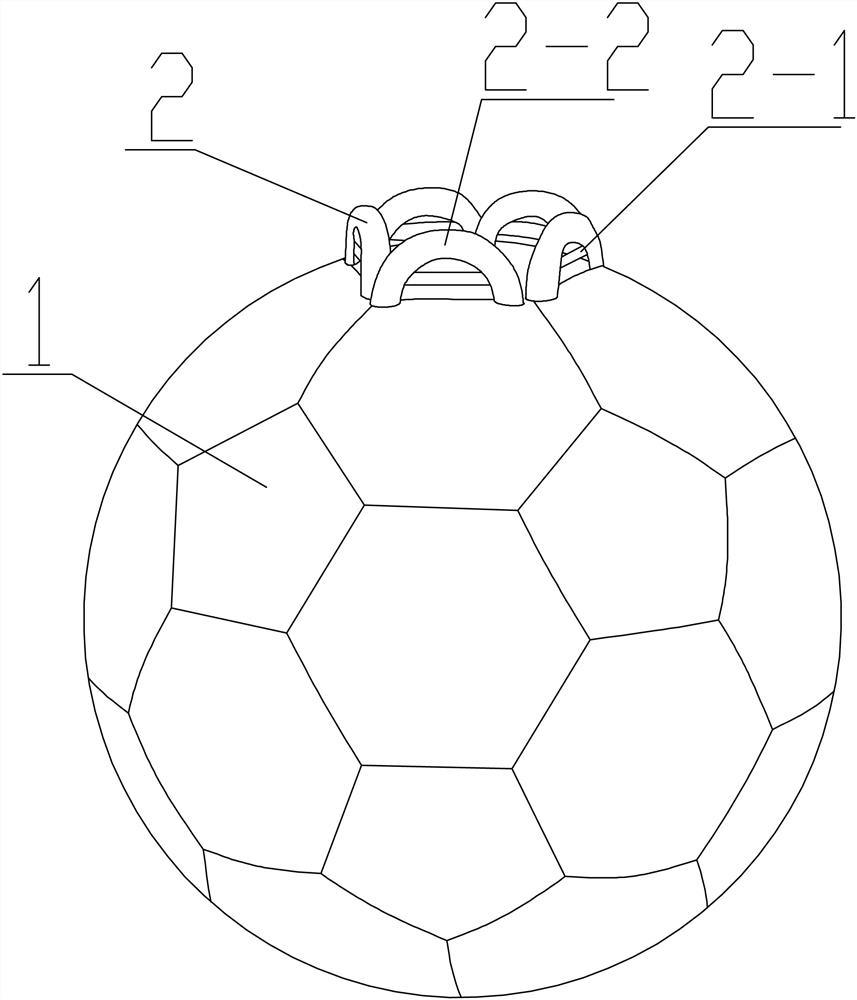

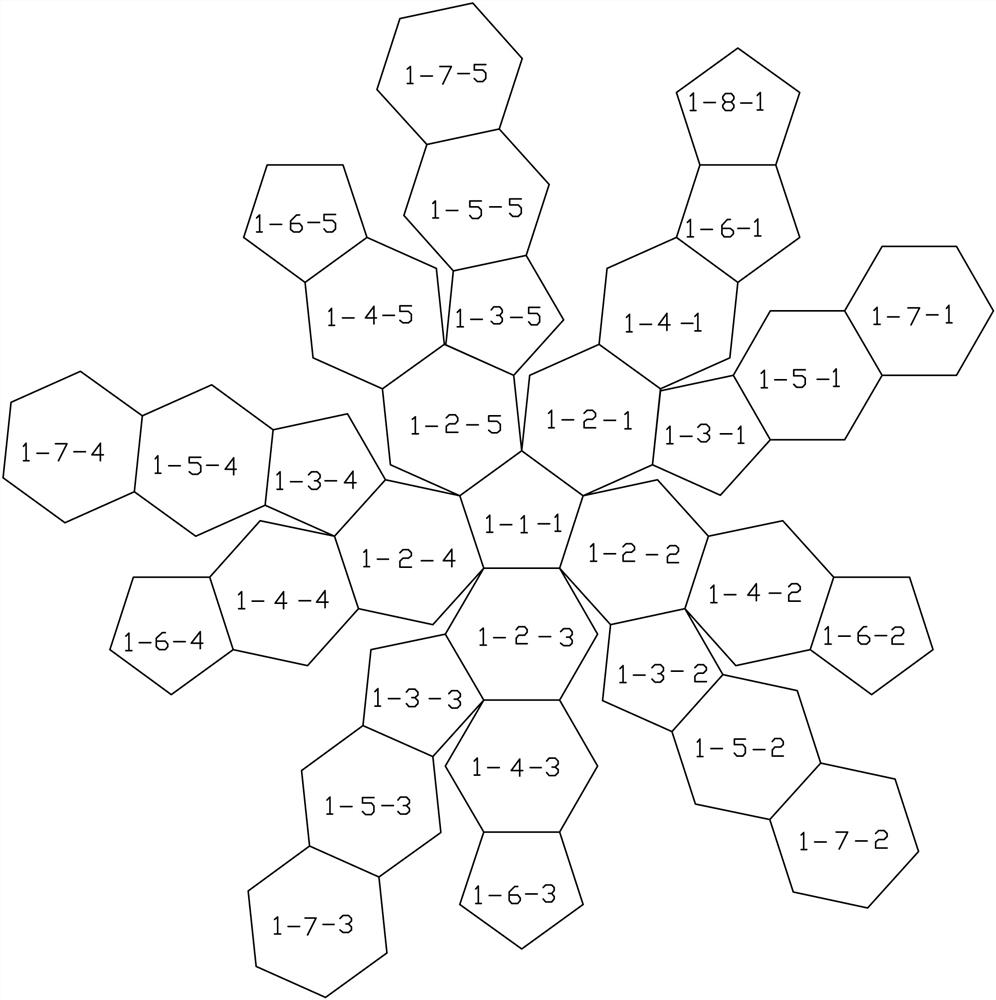

[0058] see Figure 1-4 , a measuring device for stress and strain between sand particles, which includes a protective shell 1 with a spherical structure, a plurality of pull hooks 2 are arranged on the outside of the protective shell 1, and a thin film is arranged on the inner wall of the protective shell 1 Shaped central interlayer 3, the inner wall of the central interlayer 3 is glued with an inner layer 4, and the cavity of the protective shell 1 is integrated with measurement sensing elements, signal acquisition and transmission systems, storage elements, power supply elements, and data processing and analysis elements. By adopting the above-mentioned device, the inner layer of graphene is used as a sensitive element inside the shell, and the good conductivity of graphene is used to feel the characteristics of a large change in its own resistance after a small deformation, and the conversion element in the device converts the sensitive element The sensed strain signal beco...

Embodiment 2

[0086] A method for detecting deep coral sand with a device for measuring stress and strain between sand body particles comprises the following steps:

[0087] Step 1, device use preparation: prepare weak current cables of sufficient length, stable power supply for long-term power supply, backup power supply, steel wire rope of sufficient length, operating room and workshop for placing onshore integrated devices during the construction preparation stage of building materials;

[0088] Step 2: Carry out joint survey of the dredging and reclamation project before the dredging and reclamation: use the combination of dual-frequency RTK-GPS and digital automatic sounding system for measurement, GPS provides real-time three-dimensional coordinates, and digital automatic sounding system provides synchronous water depth;

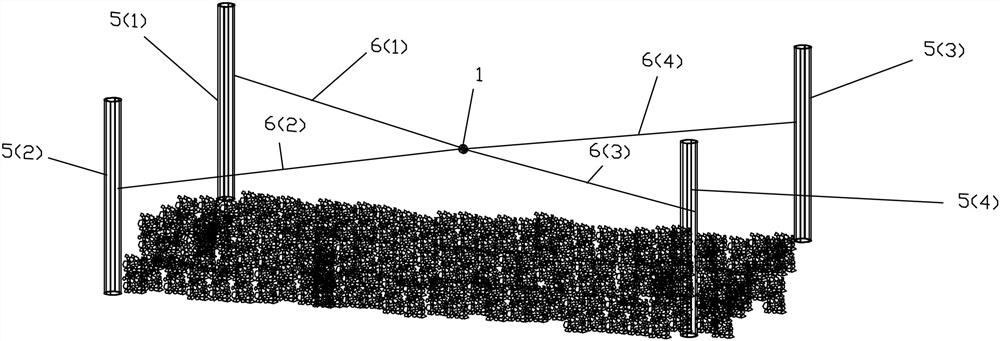

[0089] Step 3, preparatory work for the steel pipe pile 5 before filling: dig a circular hole with a diameter of 3 cm at the same depth of the prefabricated steel pi...

Embodiment 3

[0097] The specific fixed operation method of the measuring device:

[0098] Step 1: Surveyors use dual-frequency RTK-GPS combined with digital automatic sounding system for position positioning, and GPS provides real-time three-dimensional coordinates.

[0099] Step 2: The construction workers pre-drive four prefabricated steel pipe piles into the foundation according to the measurement data, and pour concrete at the positions where the steel pipe piles are driven to fill the gaps around the piles to maintain the stability of the piles.

[0100] Step 3: Fill the reef sand in the designated area. According to the requirements of the drawing, stop the filling when the filling reaches the specified height, and compact and level the coral sand in this area.

[0101] Step 4: Pass the wire rope through the positioning hole on the side wall of the pile according to the requirements of the drawings, and pull the measuring device to the designated position by the wire rope according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com