Preparation method of poly-6-hydroxyhexanoate

A technology of hydroxycaproic acid ester and hydroxycaproic acid, applied in the chemical industry, can solve the problems of unstable production process and unsatisfactory 6-hydroxycaproic acid yield, and achieve good production effect, high product quality and process safety factor. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Mix 30g of poly-6-hydroxycaproic acid and 20g of ethylene glycol in a 250ml round-bottomed flask, add 0.5g of sulfuric acid at 60°C and place it in a collector type constant temperature heating magnetic stirrer for 2 hours to obtain poly Poly 6-hydroxycaproic acid ester, then add 20ml cyclohexane in the obtained poly 6-hydroxycaproic acid ester, remove water to obtain poly 6-hydroxycaproic acid ester 28.1g, poly 6-hydroxycaproic acid ester yield 93.7 %.

Embodiment 2-5

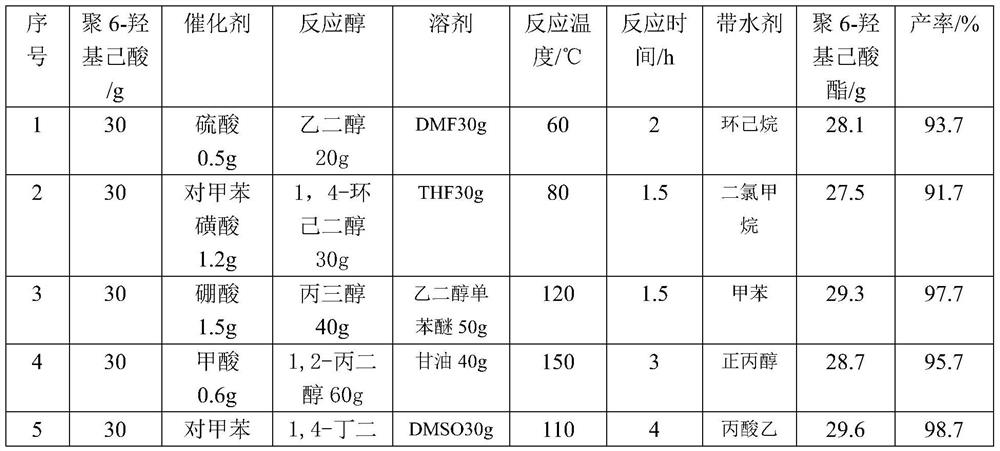

[0018] The quality of poly-6-hydroxycaproic acid is the same as in Example 1, and the others are different from Example 1, see Table 1 for details.

Embodiment 6-10

[0020] The mass of poly-6-hydroxycaproic acid is 40g, and the others are different from Example 1, see Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com