Electric mechanical lifting structure with high safety

A lifting structure and safety technology, applied in the field of electromechanical lifting structures, can solve problems such as hidden dangers, loosening safety of electromechanical lifting structures, etc., and achieve the effect of preventing potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

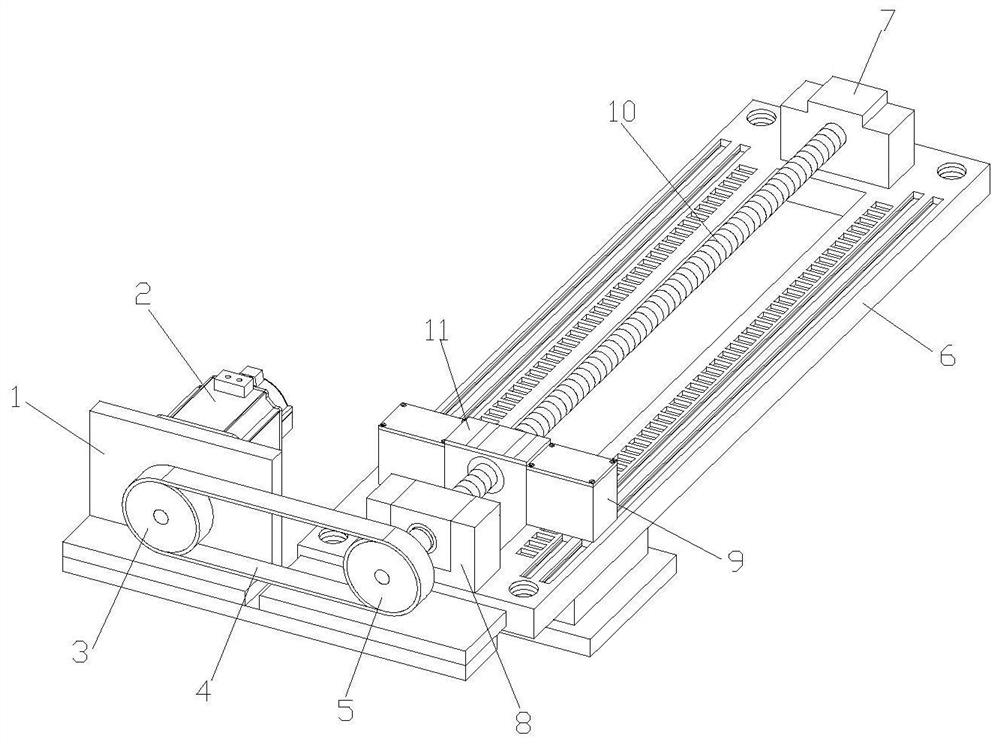

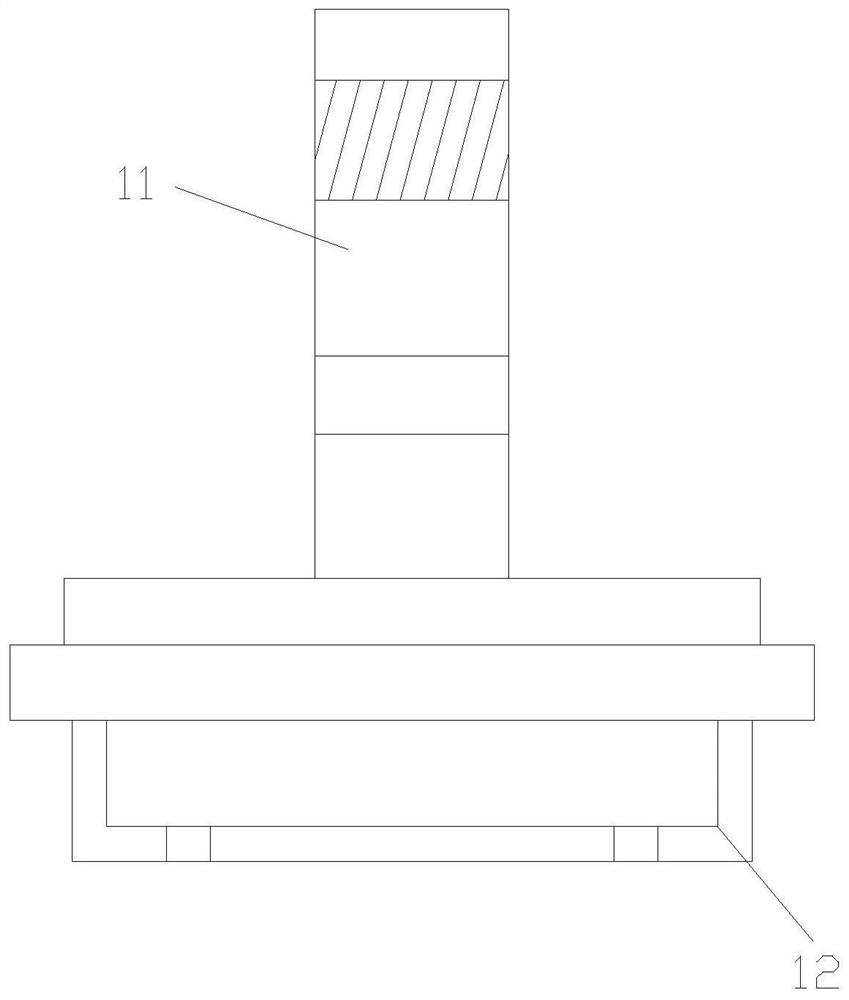

[0026] see figure 1 and figure 2 , the present invention provides a highly safe electromechanical lifting structure through improvement, including a fixed frame 1, a motor 2 and a T-shaped slide plate 11, the fixed frame 1 is installed on the rear end surface of the bottom plate 6, and the motor 2 is locked on the fixed frame 1 On the left end of the front end, the output shaft at the rear end of the motor 2 passes through the front end of the fixed frame 1 and is connected to the inner ring of the driving wheel 3. The right end face of the moving wheel 5 and the front and rear ends of the top end of the bottom plate 6 are respectively welded with a first side plate 7 and a second side plate 8, and the front and rear opposite middle parts of the first side plate 7 and the second side plate 8 rotate with the outer front and rear ends of the screw rod 10. Connection, the screw rod 10 penetrates through the middle of the rear end surface of the second side plate 8 and is fasten...

Embodiment 2

[0031] The present invention provides a high-safety electromechanical lifting structure through improvement. There are mounting holes on the top surface of the bottom plate 6, and four mounting holes are distributed on the four ends of the top surface of the bottom plate 6, so that the bottom plate 6 can be easily installed through the mounting holes. At a designated position, the mounting frame 12 is a U-shaped structure, and four ends of the bottom surface of the mounting frame 12 are provided with connection holes, which allow the mounting frame 12 to be stably connected to external objects.

[0032] The present invention provides an electromechanical lifting structure with high safety through improvement, and its working principle is as follows;

[0033] First, firstly, the whole device is fixedly installed on the designated position through the mounting hole on the top of the base plate 6, and at the same time, the external object is fixedly connected to the mounting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com