Thread splitting and winding device for textile

A winding device and textile technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as the inability to adjust the tightness of textile threads and broken threads of textile threads, so as to ensure stability and guarantee Cleanliness, the effect of meeting the needs of winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

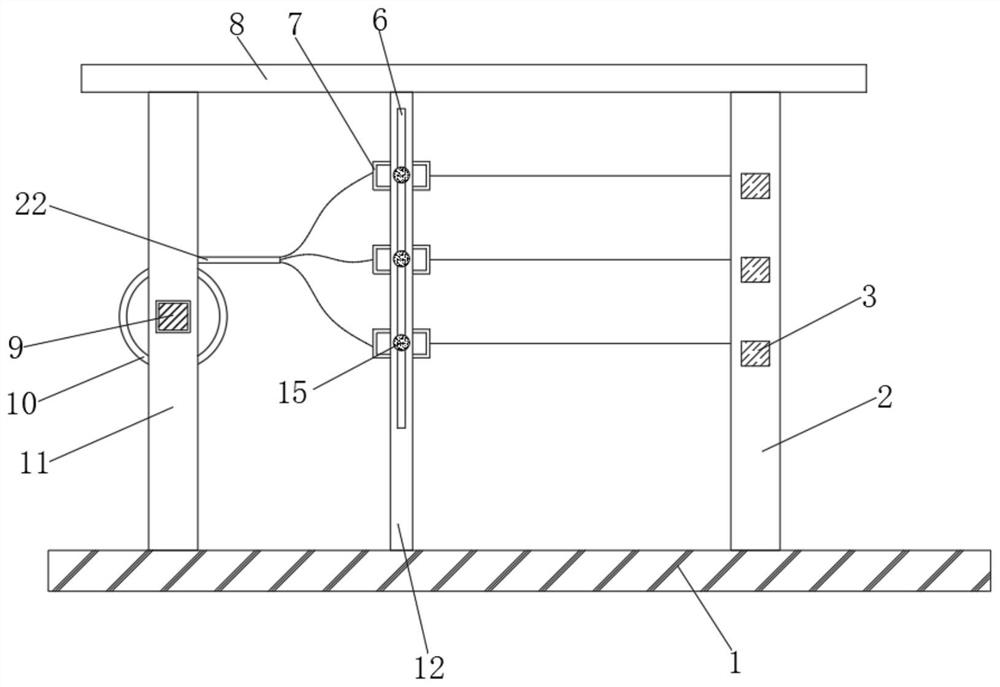

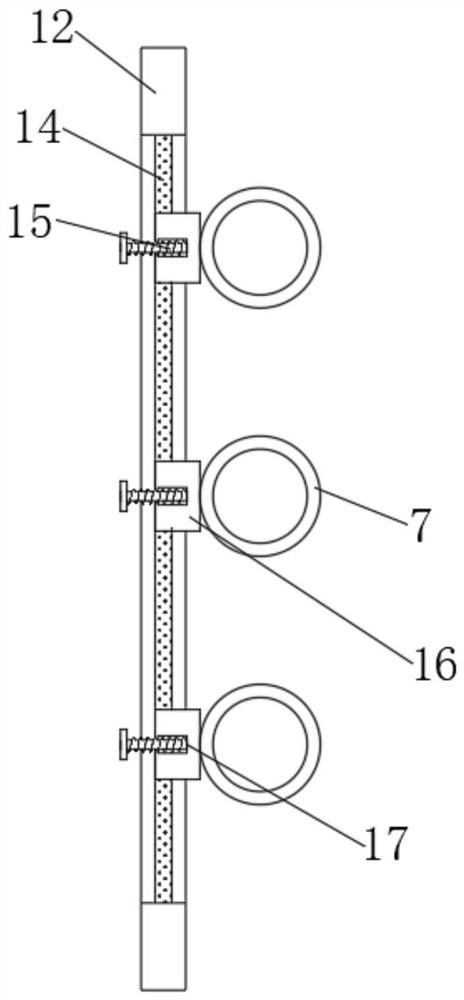

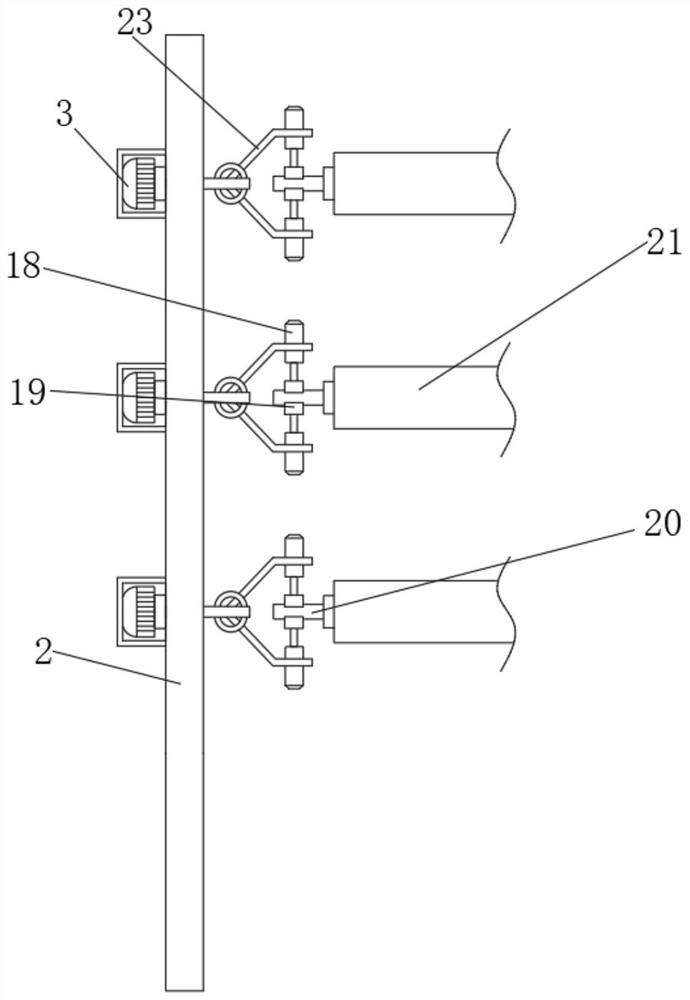

[0026] refer to Figure 1-4 , a textile branch winding device, comprising a bottom plate 1, the top outer wall of the bottom plate 1 is respectively connected with a first support plate 2 and a second support plate 11 by bolts, and the tops of the first support plate 2 and the second support plate 11 are The outer wall is connected with the top plate 8 by bolts, the one side outer wall of the second support plate 11 is connected with the third motor 9 by bolts, and the outer wall of one end of the output shaft of the third motor 9 is fixedly connected with the pay-off roller 10, and the circumference of the pay-off roller 10 The outer wall is wound with a textile thread 22, and the outer wall on one side of the first support plate 2 is connected with the first motor 3 equidistantly distributed by bolts, and the outer wall of the output shaft circumference of the first motor 3 is fixedly connected with a mounting plate 23, and the mounting plate 23- The side outer wall is plugg...

Embodiment 2

[0030] refer to Figure 5 , a textile thread winding device. Compared with Embodiment 1, the top outer wall of the top plate 8 is connected with a protective shell by bolts, and the top inner wall of the protective shell is connected with a second motor 4 by bolts. The second motor The outer wall of one end of the output shaft of 4 is fixedly connected with a brush roller 5, and the peripheral outer wall of the brush roller 5 is in contact with the textile thread 22, and the top outer wall of the bottom plate 1 is connected with a bearing seat 13 by bolts, and the brush roller 5 and the bearing seat The bottom inner wall of 13 forms a rotational connection.

[0031] Working principle: when the take-up roller 21 is winding the textile thread, the second motor 4 can be started, and the second motor 4 drives the brush roller 5 to rotate together, and the textile thread can be cleaned of dust through the rotation of the brush roller 5 , to ensure the cleanliness of the textile th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com