Raw material mixing device for production of hollow bricks

A technology for mixing devices and hollow bricks, which is applied in the direction of sales of raw material supply devices, mixing operation control devices, unloading devices, etc., can solve the problems of inability to carry out integrated crushing treatment, inability to circulate stirring, and poor mixing homogenization effect. Achieve the effects of reasonableness, compact structure, and improvement of fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

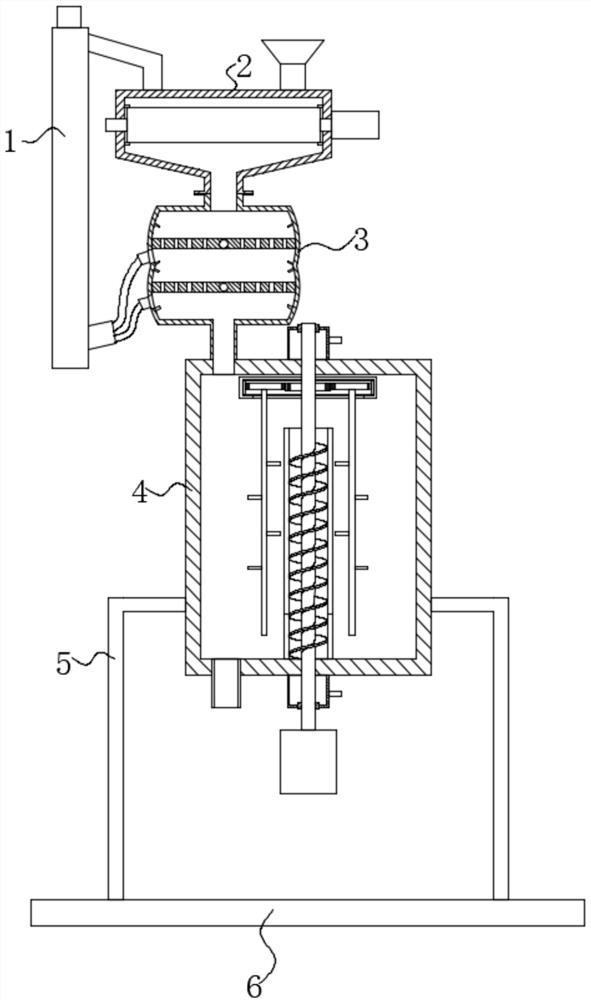

[0030] see figure 1 , this embodiment, a raw material mixing device for hollow brick production, including a feeding auger 1, a crushing box 2, a screening box 3, a mixing box 4 and a base 6, and the mixing box 4 is fixed and installed by a bracket 5 On the base 6, the scrap box 2, the screening box 3 and the mixing box 4 are connected from top to bottom, and the feeding auger 1 is installed between the scrap box 2 and the screening box 3;

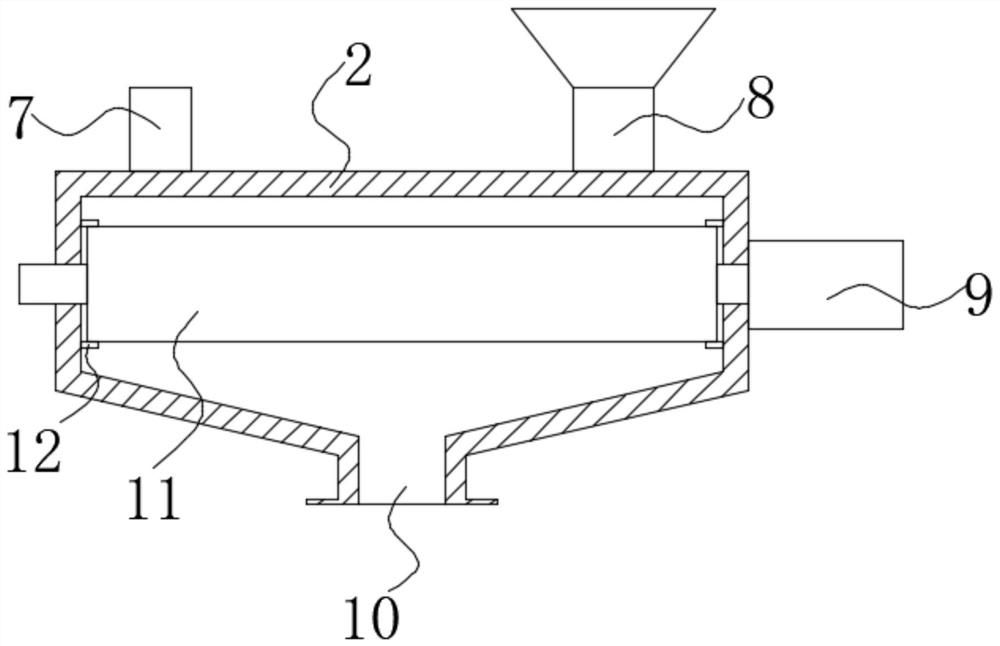

[0031] refer to figure 2 , in this embodiment, the top of the crushing box 2 is provided with a feed hopper 8 and a circulation feeding port 7, and the circulation feeding port 7 is connected to the discharge end at the top of the feeding auger 1, and the crushing The bottom of the material box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com