A kind of sealing welding process of dissimilar steel grooved tube sheet and heat exchange tube

A heat exchange tube and beveling technology, which is applied in welding equipment, manufacturing tools, metal processing, etc., can solve problems such as uneven groove root gap, heat exchange tube sloshing, spot welding position welding defects, etc., to achieve improved sealing Welding quality, effects of preventing incomplete penetration and infusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

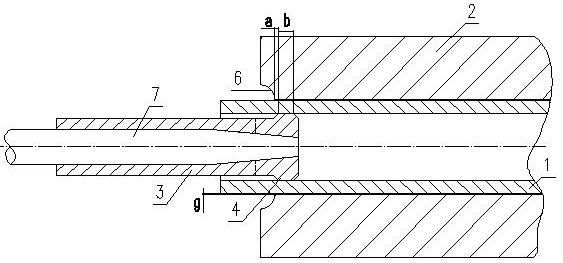

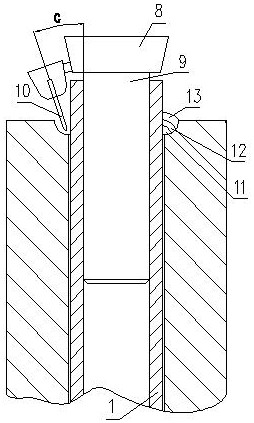

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Taking the methanol synthesis tower produced in a workshop of our company as an example, the heat exchange tube material is SA-213T11, the tube sheet material is SA-336F11CL3, and the 8mm inconel625 nickel-based alloy is surfacing. The depth of the mouth is 2.5mm. After welding, 100% radiographic inspection and penetrant inspection are required, and the anatomical test of the simulated sample is carried out. The qualification standards are ASME VIII-2 and BS EN ISO 15614-8, and the root is required to be completely penetrated and no other defects exceeding the standard.

[0020] The sealing welding process of the dissimilar steel grooved tube sheet and the heat exchange tube includes the following steps: A) Preparation: grinding and polishing the end of the tube to be welded, and cleaning the inner surface of the tube sheet hole; B) Expansion positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com