3D printing online high-temperature ultrasonic milling system based on main shaft without cooling hole

A 3D printing and milling technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as long tool life, transducer failure, poor processing performance, etc., to improve processing accuracy, air The effect of reliable cycle and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

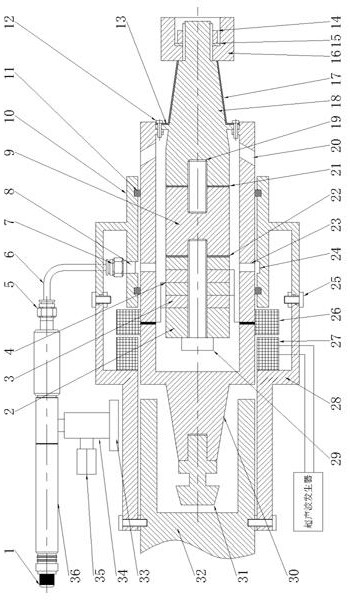

[0018] Example: see figure 1 , in the picture, 1-temperature control valve, 2-rear cover, 3-piezoelectric ceramic sheet, 4-electrode sheet, 5-trachea connector, 6-trachea, 7-trachea connector, 8-intake hole, 9- Front cover, 10-sealing sleeve, 11-sealing ring, 12-fixing bolt, 13-flange, 14-nut, 15-gasket, 16-knife, 17-first thermal insulation coating, 18-change Spindle, 19-stud, 20-air outlet, 21-second heat insulation coating, 22-third heat insulation coating, 23-knife handle air hole, 24-ring groove, 25-bolt, 26-Wireless transmission lower plate, 27-Wireless transmission upper plate, 28-Spindle shell, 29-Bolt, 30-Tool handle, 31-Tie rod, 32-Machine tool spindle, 33-Base, 34-Air pump, 35-Inlet , 36-cylinder.

[0019] A 3D printing online high-temperature ultrasonic milling system based on a spindle without cooling holes, including a wireless power transmission mechanism, an energy conversion luffing mechanism, a tool holder and an air cooling device.

[0020] The wireless p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com