Viscous eyeliner liquid with strong false eyelash adhesion as well as preparation method and application thereof

A technology of false eyelashes and eyeliner, applied in the field of viscous eyeliner and its preparation, can solve the problems of adding fine lines around the eyes, increasing the burden on the skin around the eyes, and not being able to stick firmly, so as to reduce irritation and damage and increase anti-aging. Oxidation performance, solve the effect of easy falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

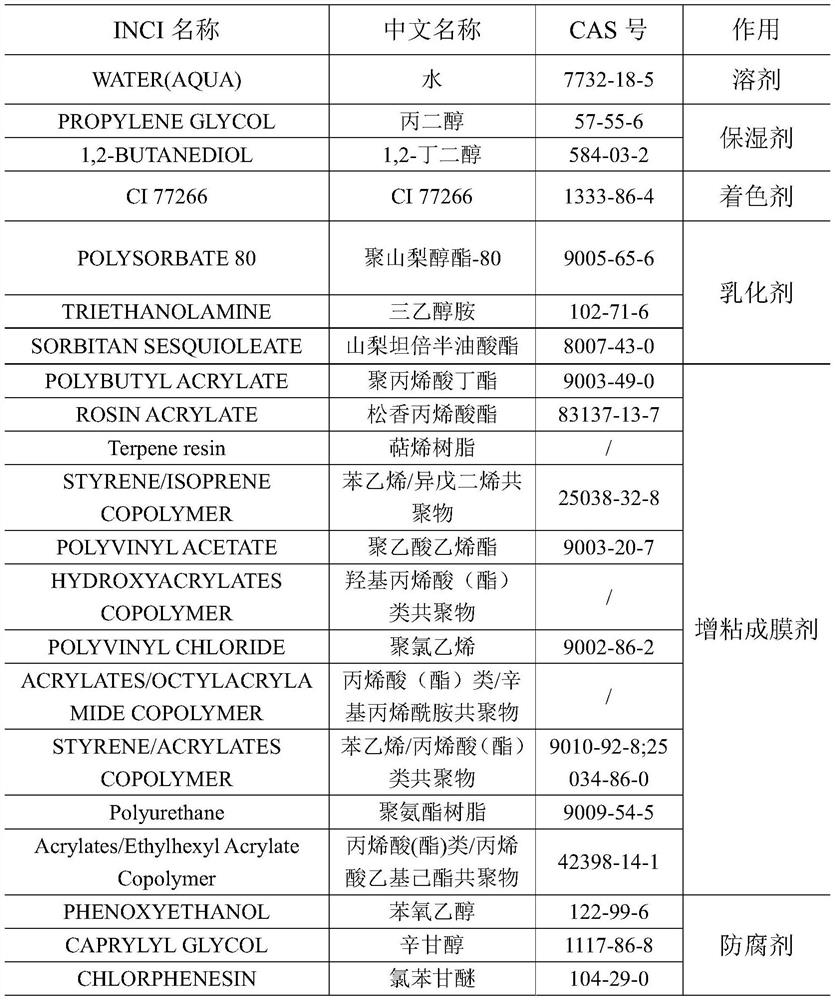

[0026] A preparation process of a viscous liquid eyeliner with strong sticky false eyelashes is as follows:

[0027] 1) Put 5% water, 3% propylene glycol, 3% polysorbate-80, 1% triethanolamine and 1% sorbitan sesquioleate into a vacuum emulsification pot, and set the vacuum degree to 10 -2 MPa, heat the emulsification pot to 85°C for vacuum emulsification reaction;

[0028] 2) Add 0.1% phenoxyethanol and 0.1% caprylyl glycol preservatives to the above emulsification pot, keep the temperature at 85°C, and stir homogeneously for 10 minutes;

[0029] 3) Add 5.2% polybutyl acrylate, 5.5% rosin acrylate, 7% terpene resin, 6% styrene / isoprene copolymer, 7% polyvinyl acetate, 8% hydroxyacrylic acid (ester) Copolymer, 9% polyvinyl chloride, 8% acrylic (ester) / octylacrylamide copolymer, 7% styrene / acrylic (ester) copolymer, 9% polyurethane resin and 9% acrylic (ester) / Thickening film-forming agent such as ethylhexyl acrylate copolymer, and 4% CI77266 coloring agent, the tempera...

Embodiment 2

[0032] A preparation process of a viscous liquid eyeliner with strong sticky false eyelashes is as follows:

[0033] 1) Put 6% water, 3% propylene glycol, 3% polysorbate-80, 3% triethanolamine and 2% sorbitan sesquioleate into a vacuum emulsification pot, and set the vacuum degree to 10 -2 MPa, heat the emulsification pot to 87°C for vacuum emulsification reaction;

[0034] 2) Add 0.1% phenoxyethanol and 0.1% caprylyl glycol preservatives to the above emulsification pot, keep the temperature at 87°C, and stir homogeneously for 10 minutes;

[0035] 3) Add 5.5% polybutyl acrylate, 6.2% rosin acrylate, 6% terpene resin, 8% styrene / isoprene copolymer, 7% polyvinyl acetate, 8% hydroxyacrylic acid (ester) Copolymer, 7% polyvinyl chloride, 6% acrylic (ester) / octylacrylamide copolymer, 6% styrene / acrylic (ester) copolymer, 9% polyurethane resin and 8% acrylic (ester) / Thickening and film-forming agents such as ethylhexyl acrylate copolymer, the temperature is maintained at 87°C...

Embodiment 3

[0038] A preparation process of a viscous liquid eyeliner with strong sticky false eyelashes is as follows:

[0039] 1) Put 6.5% water, 4% 1,2-butanediol, 2% polysorbate-80, 3% triethanolamine and 1% sorbitan sesquioleate into the vacuum emulsification pot, the vacuum degree Set to 0.1MPa, heat the emulsification pot to 83°C for vacuum emulsification reaction;

[0040] 2) Add 0.1% phenoxyethanol and 0.1% caprylyl glycol preservatives to the above emulsification pot, keep the temperature at 83°C, and stir homogeneously for 10 minutes;

[0041] 3) Add 5% polybutyl acrylate, 4.2% rosin acrylate, 7% terpene resin, 7% styrene / isoprene copolymer, 8% polyvinyl acetate, 8% hydroxyacrylic acid (ester) Copolymer, 7% polyvinyl chloride, 7% acrylic (ester) / octylacrylamide copolymer, 6% styrene / acrylic (ester) copolymer, 8% polyurethane resin and 8% acrylic (ester) / Thickening film-forming agent such as ethylhexyl acrylate copolymer, and 4% CI77266 coloring agent, the temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com