Sandwich structure bottom plate of power battery lower box body and power battery lower box body

A sandwich structure and power battery technology, applied in secondary batteries, structural parts, battery pack parts, etc., can solve problems such as insufficient impact resistance, short circuit of the battery system, damage to the water cooling plate, etc., and achieve good mechanical properties and structural rigidity High, improve the effect of corrosion resistance and stone chip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

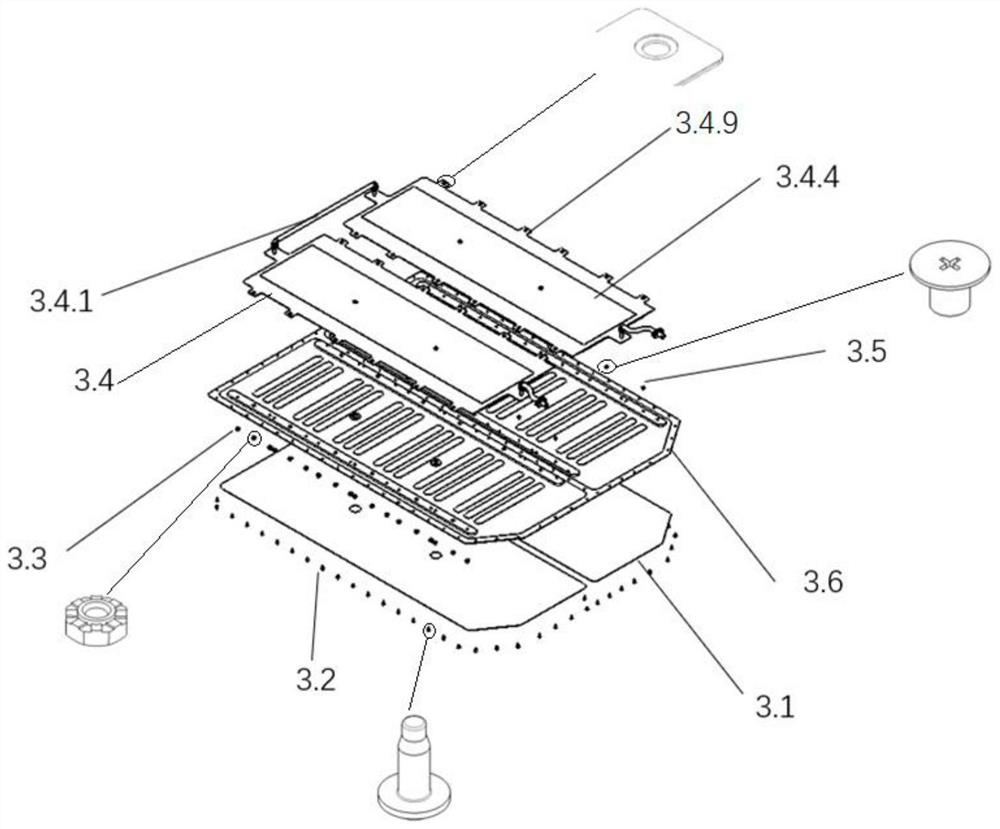

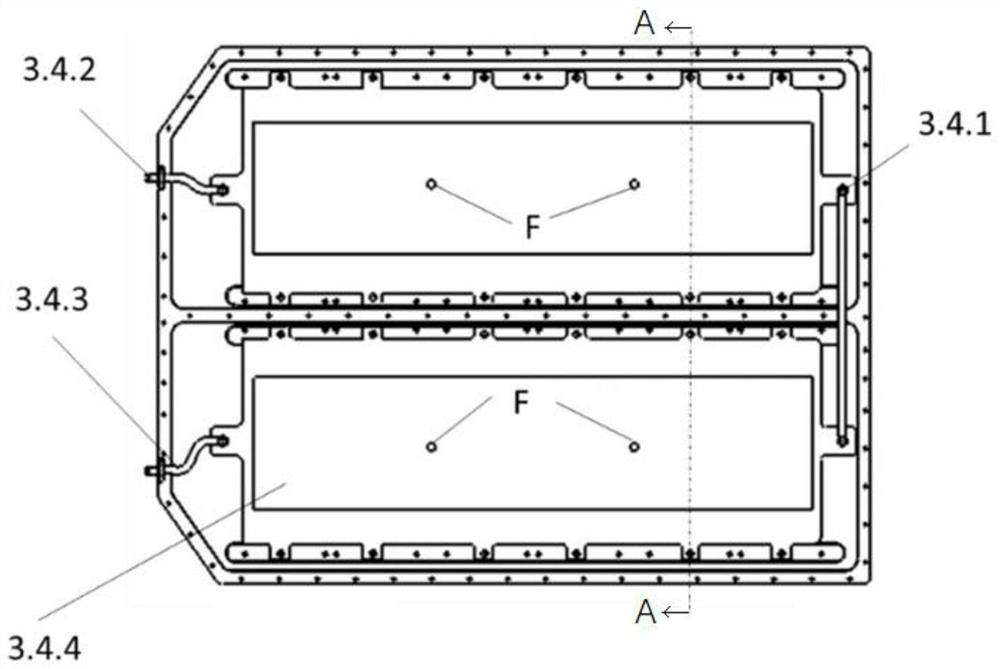

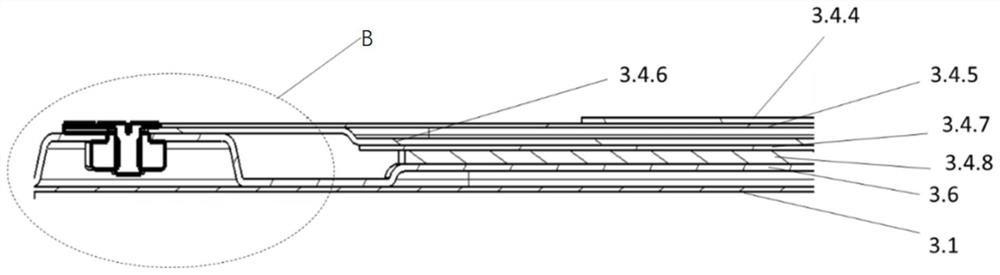

[0028] Such as Figure 1 to Figure 4 As shown, a sandwich structure bottom plate of the lower box of the power battery includes a water cooling system 3.4 layered from top to bottom, a steel punched lower bottom plate 3.6 and a carbon fiber plate 3.1; the water cooling system 3.4 includes at least one water cooling plate, water cooling There are hanger through holes 3.4.9 distributed on the board, and rivet nuts 3.3 are distributed on the stamped bottom plate 3.6. The water cooling plate fixing bolts 3.5 pass through the hanger through holes 3.4.9 and are connected with the rivet nuts 3.3 to fix the water cooling plate on the On the stamped bottom plate 3.6, the carbon fiber plate 3.1 is glued and fixed on the stamped bottom plate 3.6, and the bottom plate fastening bolts 3.2 for external connection are distributed on the stamped bottom plate 3.6. The carbon fiber plate 3.1 is bonded and sealed with the stamped bottom plate 3.6, which can improve the corrosion resistance and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com