I-shaped self-preheating burner with grading function

A type I, functional technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve the technical difficulties of NOx emissions, can not meet the requirements of NOx emissions, limited space for type I radiant tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

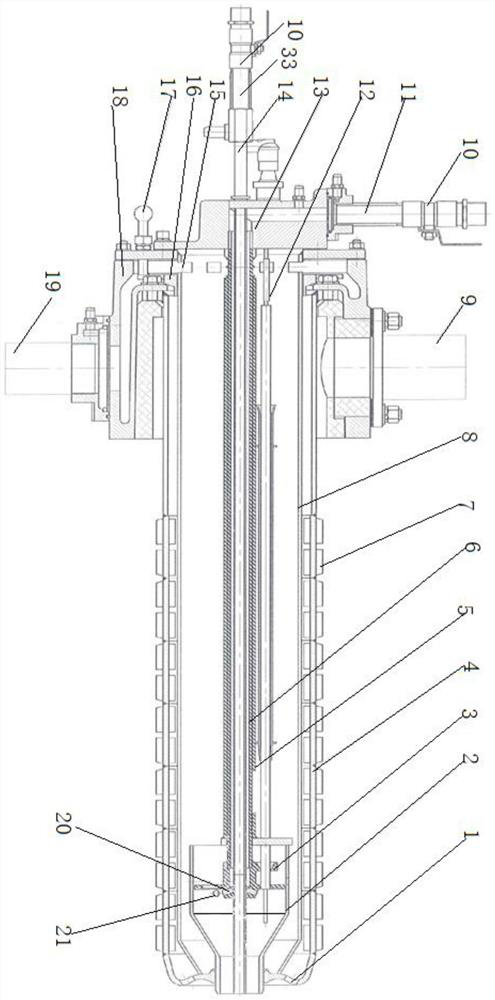

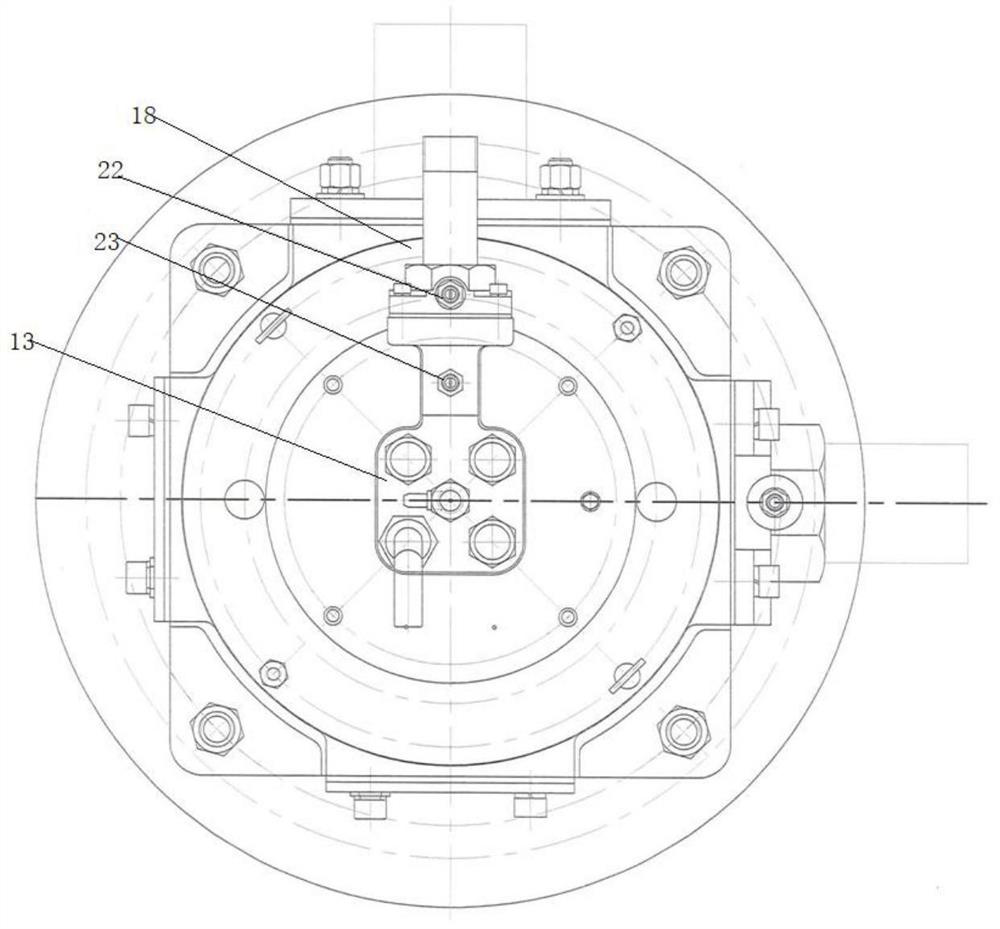

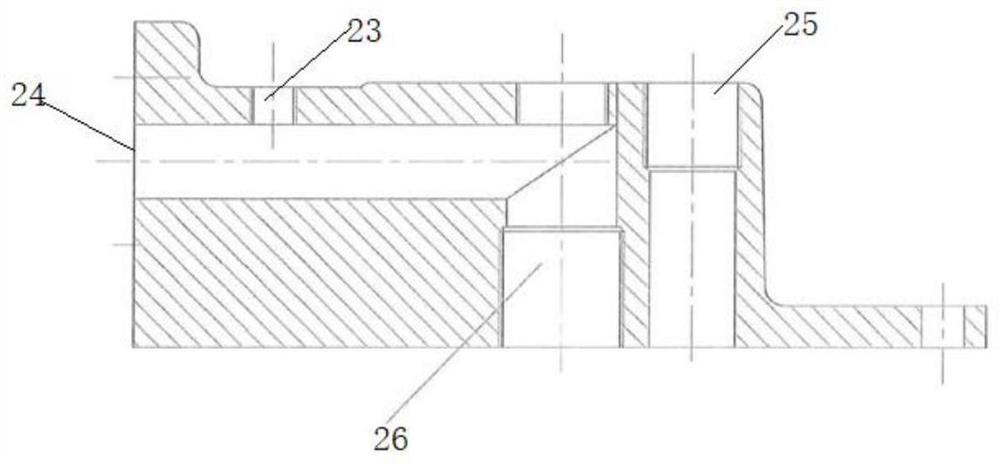

[0030] Such as Figure 1 to Figure 8 As shown, an I-type self-preheating burner with a grading function includes a shell, a heat exchange cylinder 4, an inner tube 8, a grading ring 16, a combustion chamber 2, a central tube 14, a grading tube 6, and an ignition electrode 12 ; The heat exchange cylinder 4 is set on the inner pipe 8, the head end of the heat exchange cylinder 4 is closed and is distributed with spray holes 1 which are biased forward to the axis, the tail end is open and sealed and installed on the shell, the head end of the inner pipe 8 It is closed and connected to the inside of the head end of the heat exchange cylinder 4, and the tail end is closed and installed on the shell. The grading ring 16 is slidably sleeved on the inner pipe 8 and the head end is located between the tail end of the heat exchange cylinder 4 and the inner pipe 8. The operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com