Sealed fishing tool and fishing method

A salvage tool and basket-type technology, which is applied in the field of workover operations under pressure in oil and gas fields, and can solve the problem that the salvage tool cannot be under pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

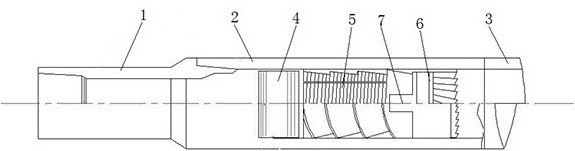

[0026]Referencefigure 1, Is a schematic structural diagram of Embodiment 1 of the present invention, a sealed fishing tool, including:

[0027]Upper joint 1;

[0028]Cylinder body 2, the inner circumferential surface of the upper end of the cylinder body 2 is threadedly connected with the lower end of the upper joint 1, and the cylinder body 2 is sequentially provided with a sealing rubber cylinder 4, a basket slip 5 and a milling control ring 6;

[0029]The guide shoe 3 is threadedly connected with the upper end of the guide shoe and the lower end of the cylinder 2. .

[0030]In actual use: the drill pipe is threaded with the upper joint 1 and drilled into the gas well. The upper joint 1, the barrel 2 and the guide shoe 3 are lowered above the falling object, and the drill pipe is slowly started to make the upper joint 1, the barrel The body 2 and the guide shoe 3 follow the rotation, and then drill down. The tip of the falling object is guided into the guide shoe 3 through the rotating shoe 3...

Embodiment 2

[0032]Referencefigure 1The difference of this embodiment is that: the inner circumferential surface of the cylinder body 2 is sequentially opened with a rubber cylinder seat, a slip cavity and a clamping groove, the sealing rubber cylinder 4 is embedded in the rubber cylinder seat, and the milling control The ring 6 is embedded in the slot, the basket slip 5 is arranged in the slip cavity, the upper end of the basket slip 5 is in contact with the lower end of the sealant cylinder 4, and the lower end of the basket slip 5 is in contact with the milling control The upper end of the ring 6 contacts.

[0033]In actual use: when the sealant cylinder 4 is squeezed, the sealant cylinder 4 is limited by the cylinder seat to move upward, causing the sealant cylinder 4 to expand inward and outward at the same time, and the sealant cylinder 4 is squeezed into the sealing seat. At the same time, the sealant cylinder 4 can restrict the falling objects from passing through the basket slip 5 and cont...

Embodiment 3

[0035]Referencefigure 1The difference of this embodiment is that the cylinder 2, the sealant cylinder 4, the basket slip 5 and the milling control ring 6 are coaxial.

[0036]In actual use: the cylinder body 2, the sealant cylinder 4, the basket slip 5 and the milling control ring 6 are coaxial, which can ensure that the falling objects can be correctly guided into the basket slip 5 and prevent the falling objects from being biased against the sealant cylinder 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com