Fabricated steel structure building assembly and fabrication method

A technology of building components and steel structures, which is applied in the direction of construction and building construction, can solve difficult problems, achieve the effect of improving bearing capacity and facilitating assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

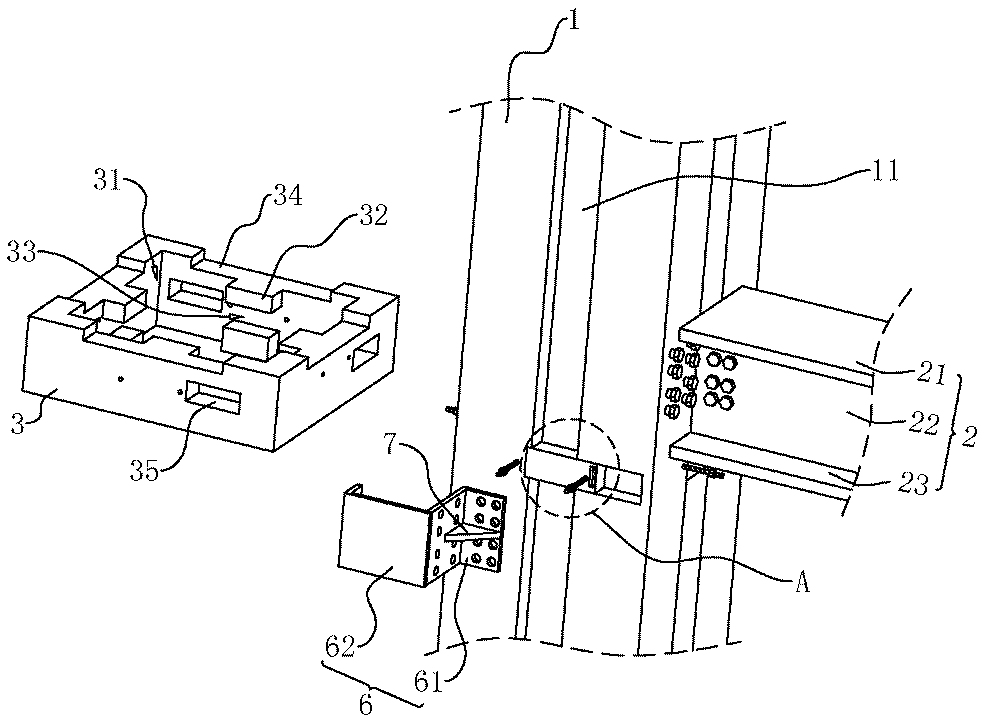

[0037] The following is attached Figure 2-4 The application is described in further detail.

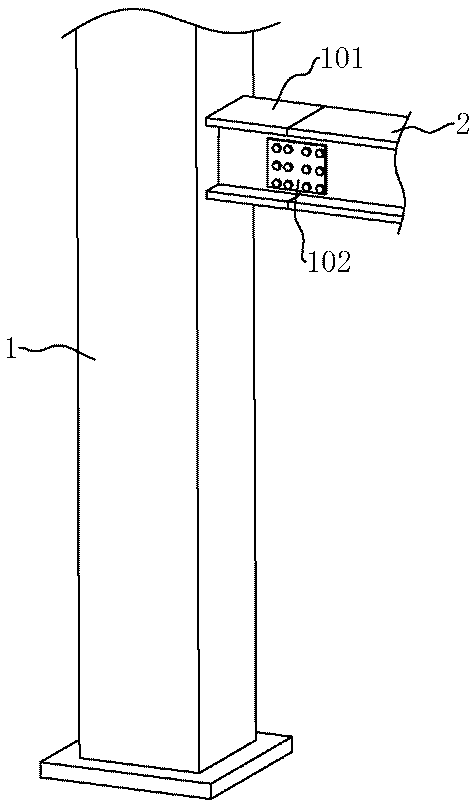

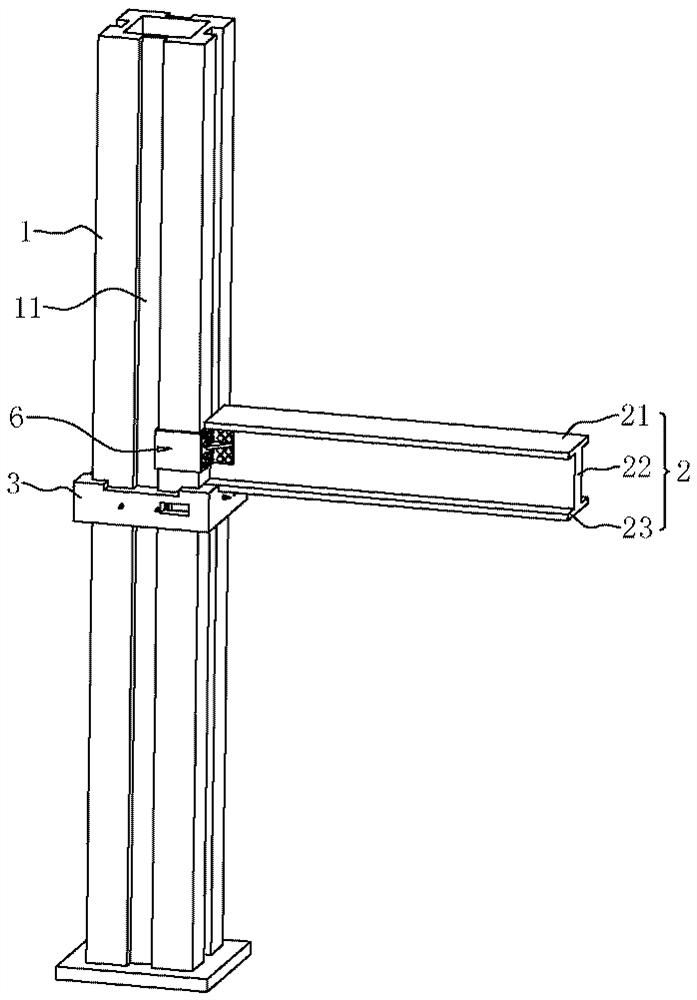

[0038] The embodiment of the present application discloses a prefabricated steel structure building component. refer to figure 2 , The steel structure building assembly includes a column 1 and a beam 2, the column 1 is vertically arranged, the column 1 is a hollow steel pipe, the column 1 is provided with a load-bearing block 3, and the load-bearing block 3 is fixedly connected to the column 1 through a first fixture. The end of the beam 2 is built on the load-bearing block 3 , and the beam 2 is fixedly connected with the column 1 through the second fixing piece 6 . The load-bearing blocks 3 are fixed on the column 1, and the load-bearing blocks 3 at both ends of the beam 2 are located on the same horizontal plane. The two ends of the beam 2 are built on the load-bearing block 3, and the load-bearing block 3 positions the beam 2 so that the beam 2 is in a horizontal state.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com