Beam slab temporary support capable of achieving simple supporting first and then continuous operation and using method thereof

A technology of simple support first and then continuous and temporary support, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of cumbersome sand tank settlement test, low accuracy of adjustment and control of sand tank settlement, etc., to achieve Improve application stability, simple structure, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

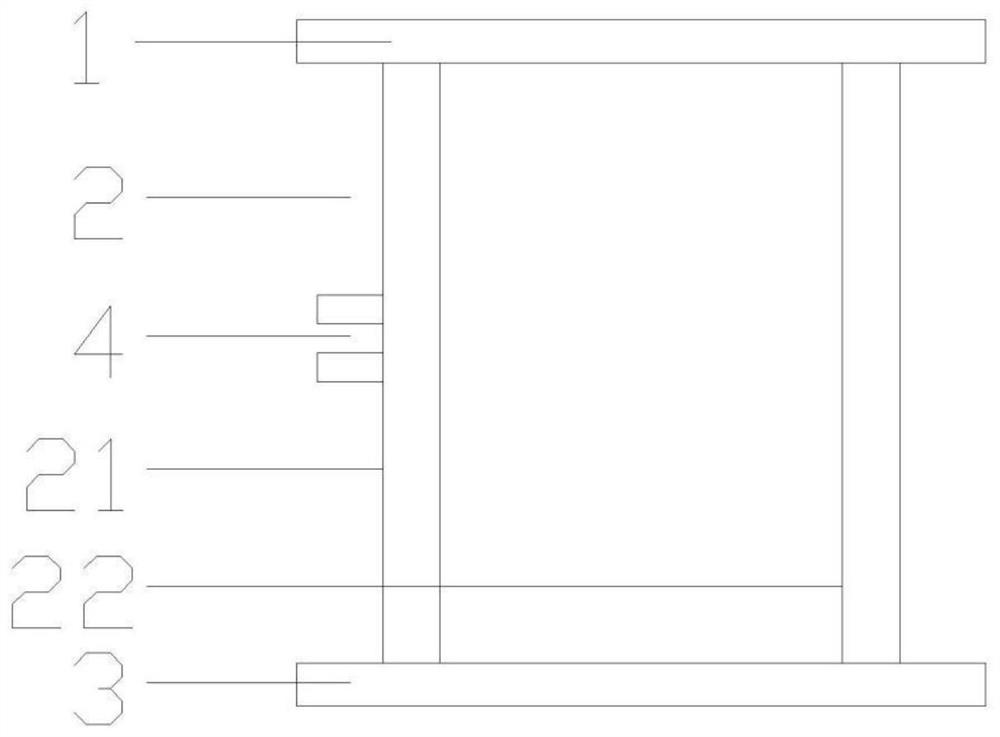

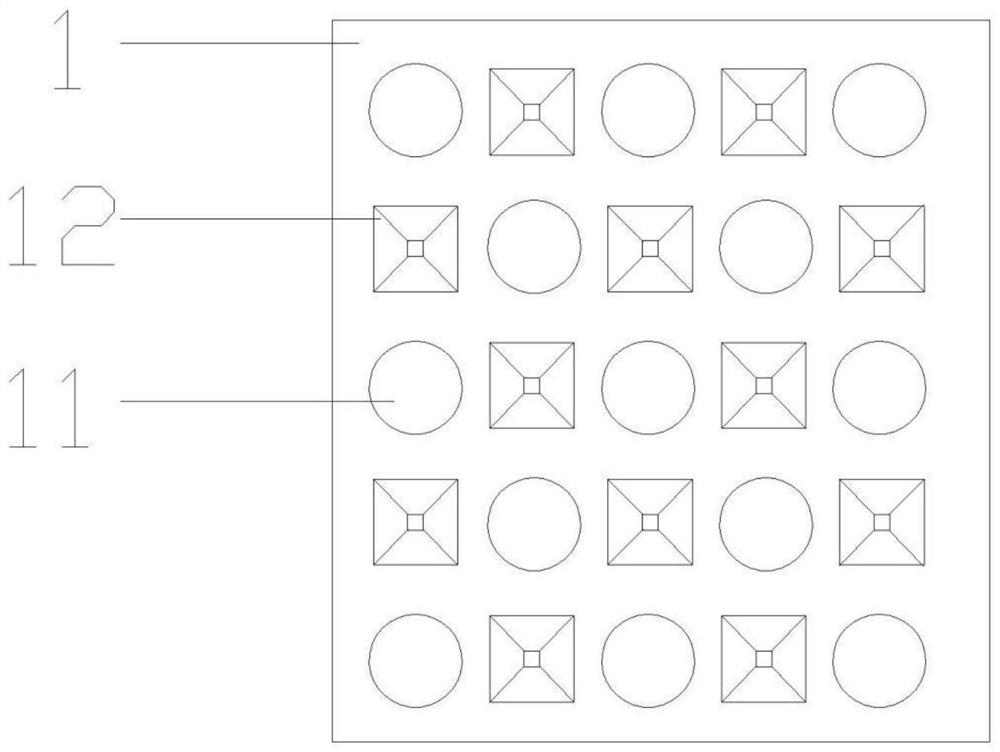

[0054] Such as figure 1 with Figure 4 As shown, a temporary beam-slab support that is simply supported first and then continuous, including:

[0055] The top steel plate 1, the upper surface of the top steel plate 1 abuts against the bottom end of the beam body 5 to support the beam body 5;

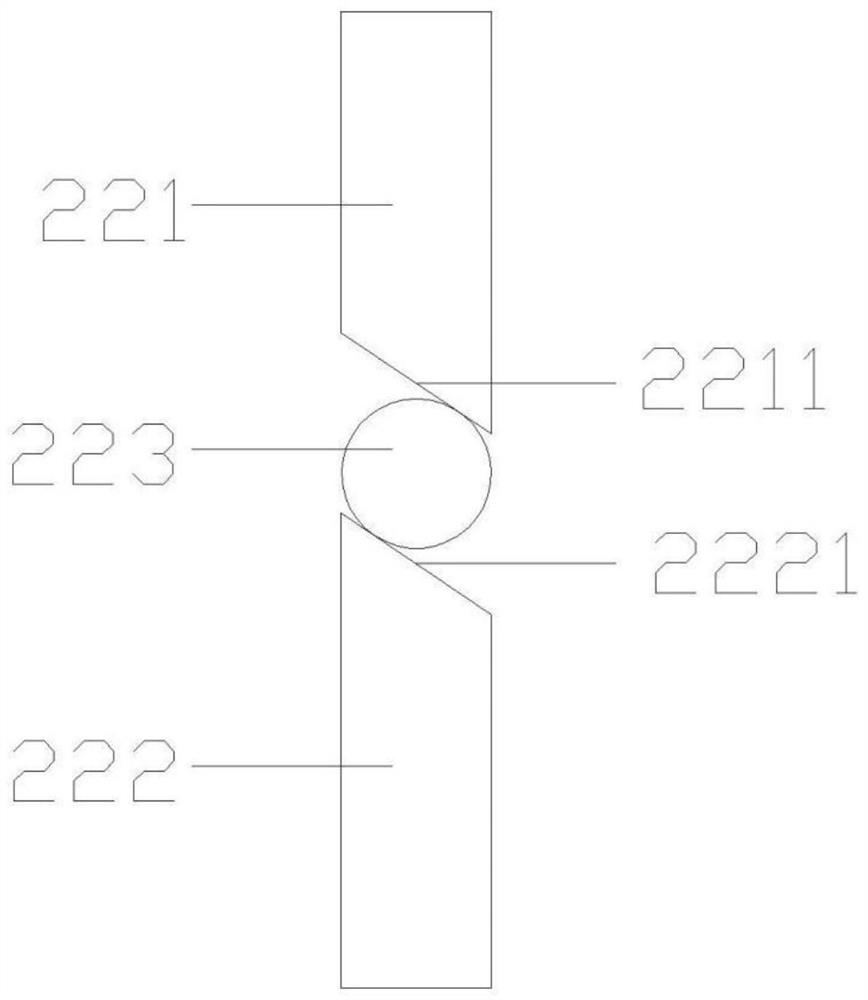

[0056] The supporting steel plate 2, the upper end of the supporting steel plate 2 is fixedly connected to the top steel plate 1;

[0057] The bottom steel plate 3, the lower end of the support steel plate 2 is fixedly connected to the bottom steel plate 3, and the lower surface of the bottom steel plate 3 abuts against the top of the pad;

[0058] The cutting groove 4 is fixedly arranged on the outer side of the supporting steel plate 2 to guide the oxyacetylene cutting device.

[0059] In the previous engineering construction, the oxyacetylene cutting device was manually operated, and the incision was not neat, which made it difficult to take out the temporary support.

[0060] In ...

Embodiment 2

[0081] In step 2.1, before placing the temporary support, it also includes the step of preparing the pad stone roof:

[0082] Step 2.11, grinding the upper surface of the pad stone top so that the upper surface of the pad stone top is relatively horizontal;

[0083] Step 2.12, prepare anti-carbonization coating, adopt 10 parts of cement, 12 parts of steel slag powder, 16 parts of styrene-acrylic emulsion, 2 parts of polyvinyl formal, 2 parts of rosin, 3 parts of ammonium acrylate, 0.2 parts of Dispersant, 0.1 part of antifoaming agent and 0.1 part of stabilizer, the above-mentioned components are by mass, and the above-mentioned components are mixed and stirred until milky, and the anti-carbonization coating is obtained;

[0084] Step 2.13, use a paint spray gun to spray on the upper surface and side wall of the pad stone roof. After the spraying is completed, wait for the anti-carbonization coating to dry naturally, and then spray again. After the anti-carbonization coating i...

Embodiment 3

[0086] In step 1, the step of fixing the pressure sensor on the top steel plate 1 is also included.

[0087] In step 2.3, the pressure values of the temporary supports on the first pier and the second pier are collected to confirm that the gravity of the girder is not all pressed on the temporary supports.

[0088] In step 2.4, the pressure values of the temporary supports on the first pier and the second pier are collected again to confirm that the gravity of the beam body is all pressed on the temporary supports.

[0089] In the actual application process, the pressure value of each temporary support is displayed on the display interface of the operator of the beam hoisting equipment, and the operator judges the stress state of each temporary support according to the pressure value displayed on the display interface. This is used to control the operation of the beam lifting equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com