Brewing process for flavored vinegar

A flavor and process technology, applied in the field of flavor vinegar brewing process, can solve the problems of loss of nutrients, waste of resources, over-oxidation, etc., and achieve the effects of increasing the content of alcohol and acetic acid, avoiding bacterial infection, and reducing the degree of decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

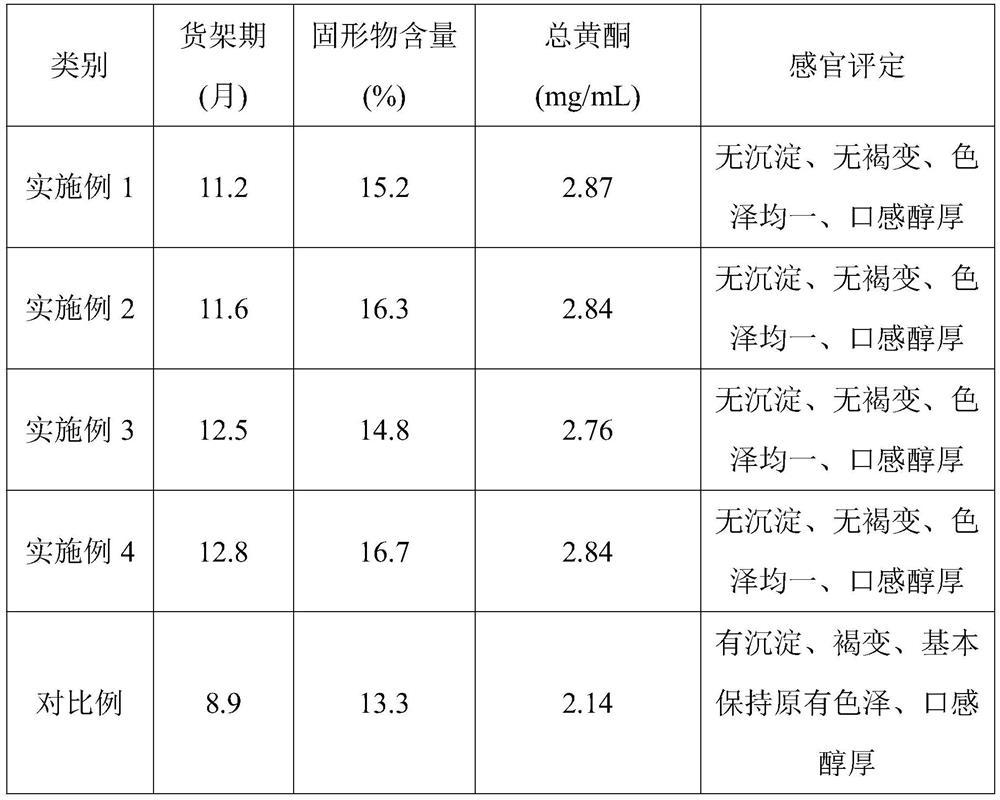

Examples

Embodiment 1

[0027] A brewing process of flavor vinegar is characterized in that it comprises the following steps:

[0028] (1) Raspberry slurry: after cleaning the raspberries, mix the raspberries and sterile water with a volume ratio of 1:11 for beating to obtain a raspberry slurry;

[0029] (2) Glutinous rice slurry: after the glutinous rice is rinsed and washed, the glutinous rice and sterile water are mixed in a volume ratio of 1:4.5, after soaking for 6.5 hours, the glutinous rice slurry is obtained after beating by a refiner;

[0030] (3) Antioxidant preparation of green walnut skin: wash and dry the green walnut skin, pass through an 80-mesh sieve after crushing, add degreasing agent to the green walnut skin, treat it under standing conditions for 5 hours, remove the degreasing agent, and then repeat the treatment 2 times, Collecting the pretreated walnut green husk powder; soaking the pretreated walnut green husk powder in ethanol solution, leaching for 5 hours under ultrasonic-as...

Embodiment 2

[0039] A brewing process of flavor vinegar is characterized in that it comprises the following steps:

[0040] (1) raspberry slurry: after the raspberry is cleaned, the raspberry and sterile water are mixed and beaten in a volume ratio of 1:10 to obtain the raspberry slurry;

[0041] (2) Glutinous rice slurry: after the glutinous rice is rinsed and washed, the glutinous rice and sterile water are mixed in a ratio of 1:3 by volume, after soaking for 6 hours, the glutinous rice slurry is obtained after beating by a refiner;

[0042] (3) Antioxidant preparation of green walnut skin: wash and dry the green walnut skin, pass through an 80-mesh sieve after crushing, add degreasing agent to the green walnut skin, treat it under standing conditions for 5 hours, remove the degreasing agent, and then repeat the treatment 2 times, Collecting the pretreated green walnut peel powder; soaking the pretreated green walnut peel powder in ethanol solution, leaching for 4 hours under the assiste...

Embodiment 3

[0051] A brewing process of flavor vinegar is characterized in that it comprises the following steps:

[0052] (1) raspberry slurry: after the raspberry is cleaned, the raspberry and sterile water are mixed and beaten in a volume ratio of 1:12 to obtain the raspberry slurry;

[0053] (2) Glutinous rice slurry: after the glutinous rice is washed clean, the glutinous rice and sterile water are mixed in a volume ratio of 1:4, after soaking for 5.5 hours, the glutinous rice slurry is obtained after beating by a refiner;

[0054] (3) Antioxidant preparation of green walnut skin: wash and dry the green walnut skin, pass through an 80-mesh sieve after crushing, add degreasing agent to the green walnut skin, treat under standing conditions for 6 hours, remove the degreasing agent, and then repeat the treatment for 2-3 The second step is to collect the pretreated green walnut peel powder; soak the pretreated green walnut peel powder in ethanol solution, and under the assisted condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com