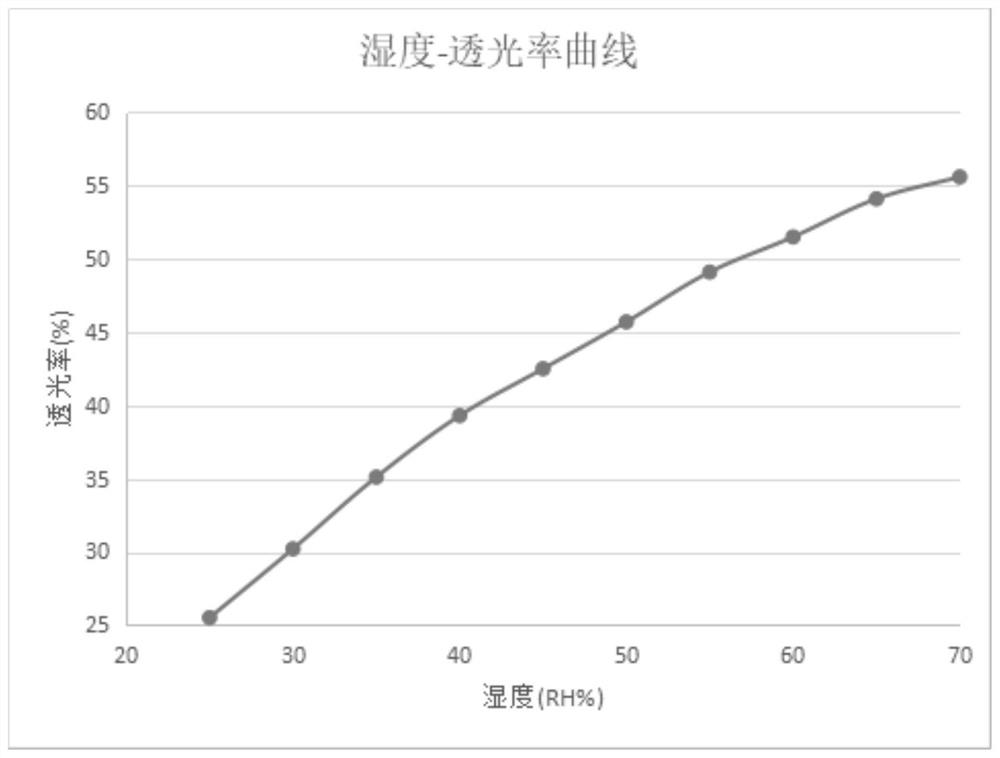

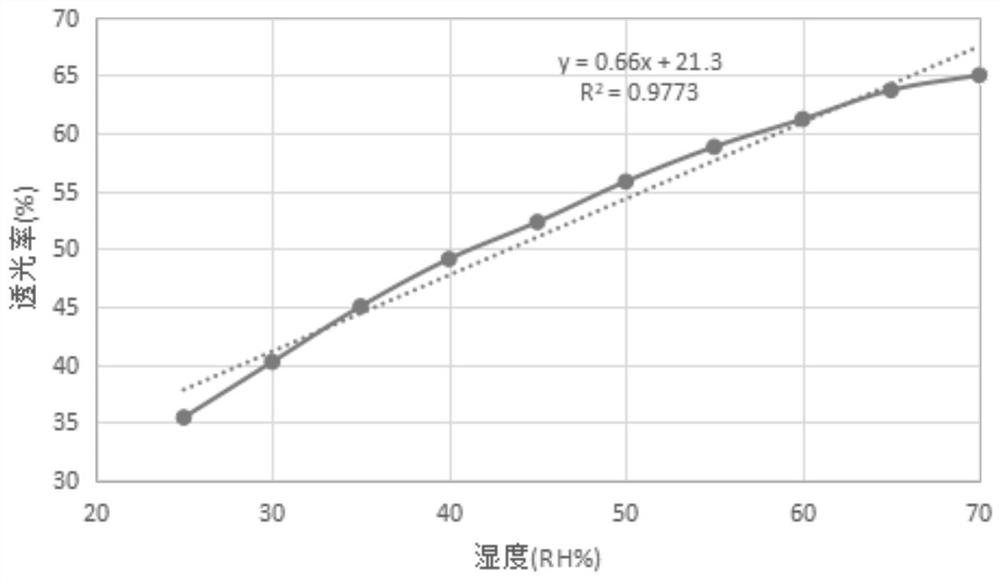

Composite test material with light transmittance changing along with humidity as well as preparation method and application of composite test material

A technology of humidity change and light transmittance, applied in the direction of transmittance measurement, etc., can solve the problems of inability to accurately obtain the water content inside the cable, unable to meet the demand, etc., and achieve the effect of facilitating mass production, good market prospects, and accurate judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 40 parts of hydroxyl-modified acrylic water-absorbing resin (weight-average molecular weight of 50000, hydroxyl value of 65 mg KOH / g, vinyl content of 1.9 wt%), 10 parts of polyurethane acrylic resin, 15 parts of vinyl MQ silicone resin (vinyl content of 3.3 wt%, viscosity 5600mPa s), 1 part of diisononyl phthalate, 3 parts of melamine phosphate and 150 parts of acetone to prepare a uniform dispersed phase, and add 0.05 parts of azobisisobutyronitrile under stirring conditions, Heat to 110°C and react for 6 hours to obtain a mixed resin; after infrared testing, the carbon-carbon double bond basically disappears, indicating that the polymerization reaction is sufficient; then 6 parts of ultrafine calcium carbonate and 3 parts of aluminum hydroxide are ground and put into the above mixed resin, fully After stirring for 1 hour, vacuum drying was carried out in a vacuum oven at 150° C. for 3 hours in a vacuum environment of 0.1 MPa to obtain a composite test material.

Embodiment 2

[0042] Other conditions and steps are the same as in Example 1, except that the hydroxyl group content of the hydroxyl-modified acrylic water-absorbing resin is 93 mg KOH / g, and the vinyl content is 1.2 wt %; the vinyl content of the vinyl MQ silicone resin is 4.6 wt %, and the viscosity is 4500 mPa. s.

Embodiment 3

[0044] Other conditions and steps are the same as in Example 1, except that the hydroxyl group content of the hydroxyl-modified acrylic water-absorbing resin is 82 mg KOH / g, and the vinyl content is 1.3 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com