Preparation method and application of carbon nanotube wrapped nitrogen-doped porous carbon composite material

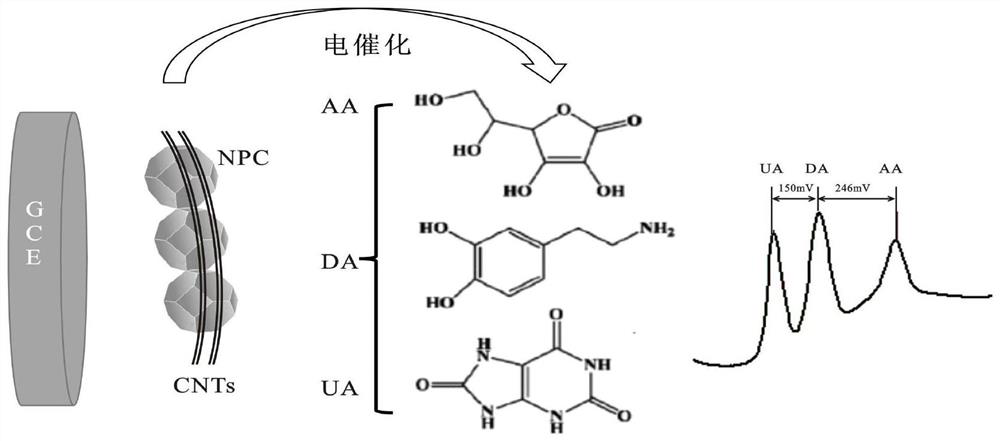

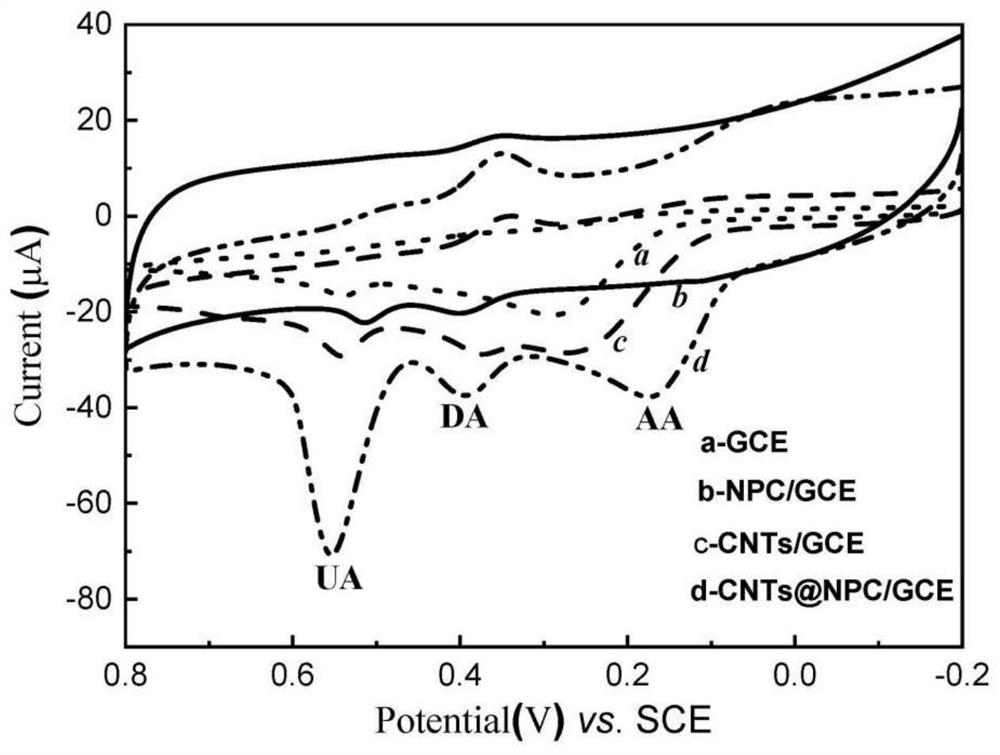

A technology of nitrogen-doped porous carbon and carbon nanotubes, which is applied in the preparation/purification of carbon, analytical materials, nanotechnology, etc., can solve the problems of narrow linear range, high detection limit, complex preparation process, etc., and achieve electrochemical signal The effect of sensitive response, high accuracy and reproducibility, and high peak resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033](1) Weigh 100 mg carboxylated carbon nanotubes and 2 g of polyvinylpyrrolidone (PVP, WM = 40000) in the beaker, add 200 ml of deionized water, and the magnetic force is stirred after 15 min, washed with ultrapure water and centrifuged 4 times. The activated carbon nanotubes were obtained after drying at 70 ° C in an oven.

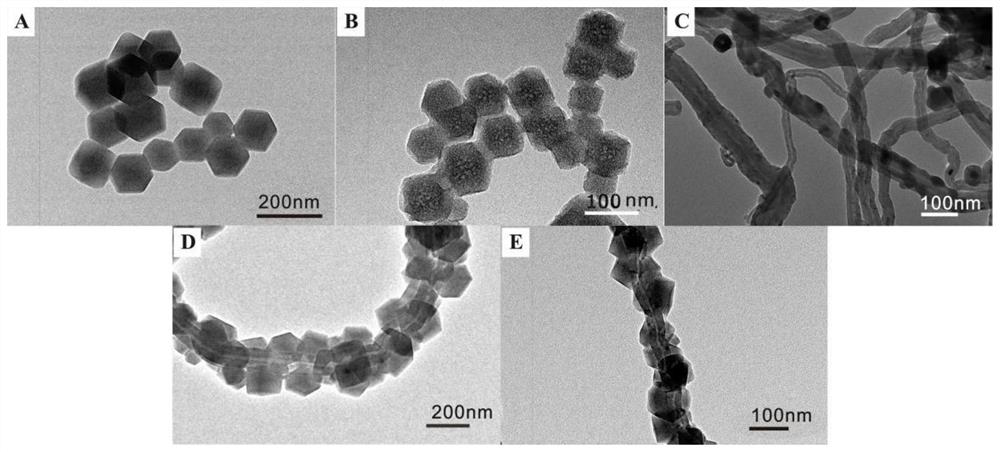

[0034](2) Weigh 421mg (1.42 mmol) hexahydrate zinc (Zn (NO)3)2· 6h2O), in a 20 mL methanol solvent, 110 mg of activated carbon nanotubes were added. After stirring for 10 h, it was poured into 8 ml of 873 mg (10.65 mmol) 2-methylimidazole methanol solution, stirred for 5 h. , Was washed with methanol and centrifuged 3 times, and then CNTS @ ziF-8 material was prepared after 30 h at 70 ° C in an oven.

[0035](3) CNTS @ ZIF-8 prepared by step (2) is placed in a porcelain boat, under argon conditions, in the tube furnace in the tube furnace at a heating rate of 5 ° C / min lasts 1.5 h, and the resulting solid The powder was fully impregnated with 40 ml of 1.5 mol / ...

Embodiment 2

[0038](1) Weigh 150 mg of carboxylated carbon nanotubes and 4 g of polyvinylpyrrolidone (PVP, WM = 40000) in the beaker, add 400 ml of deionized water, and the magnetic force is stirred after 25 min, washed with ultrapure water and centrifuged 4 times, The activated carbon nanotube was obtained after drying at 90 ° C in an oven.

[0039](2) Weigh 421mg (1.42 mmol) hexahydrate zinc (Zn (NO)3)2· 6h2O), in a 30 mL methanol solvent, 120 mg of activated carbon nanotubes were added, and after stirring for 12 h, it was poured into 12 ml of 573 mg (10.65 mmol) 2-methylimidazole methanol solution, stir for 6 h. After washing with methanol and centrifuged 3 times, the CNTS @ ziF-8 material was subsequently prepared at 75 ° C in an oven.

[0040](3) Place the CNTS @ ziF-8 prepared by step (2) in a porcelain, under argon conditions, in the tube furnace at a temperature of 5 ° C / min last temperature to 850 ° C for 2.5 h, the resulting solid The powder was fully impregnated with 40 ml of 2.5 mol / L ...

Embodiment 3

[0043](1) Weigh 150 mg of carboxylated carbon nanotubes and 3 g of polyvinylpyrrolidone (PVP, WM = 40000) in the beaker, add 300 ml of deionized water, and the magnetic force is stirred after 20 min, washed with ultrapure water and centrifuged 4 times, The activated carbon nanotubes were obtained after drying at 80 ° C in an oven.

[0044](2) Weigh 421mg (1.42 mmol) hexahydrate zinc (Zn (NO)3)2· 6h2O), in a 25 mL methanol solvent, 115 mg of activated carbon nanotubes were added, and after stirring for 12 h, it was poured into 10 ml of 573 mg (10.65 mmol) 2-methylimidazole methanol solution, stir for 6 h. After washing with methanol and centrifuged 3 times, the CNTS @ ziF-8 material was prepared after 24 h at 80 ° C in an oven.

[0045](3) Place the CNTS @ ziF-8 prepared by step (2) in a porcelain, under argon conditions, in the tube furnace at a temperature of 5 ° C / min last temperature to 900 ° C for 2 h, and the resulting solid powder The aqueous hydrochloric acid placed in 50 ml of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com