Component conveying device and method

A technology for conveying devices and components, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of scrapped products, easy sliding of components, troublesome product inspection, etc., to improve safety and solve the effect of low efficiency of repetitive work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

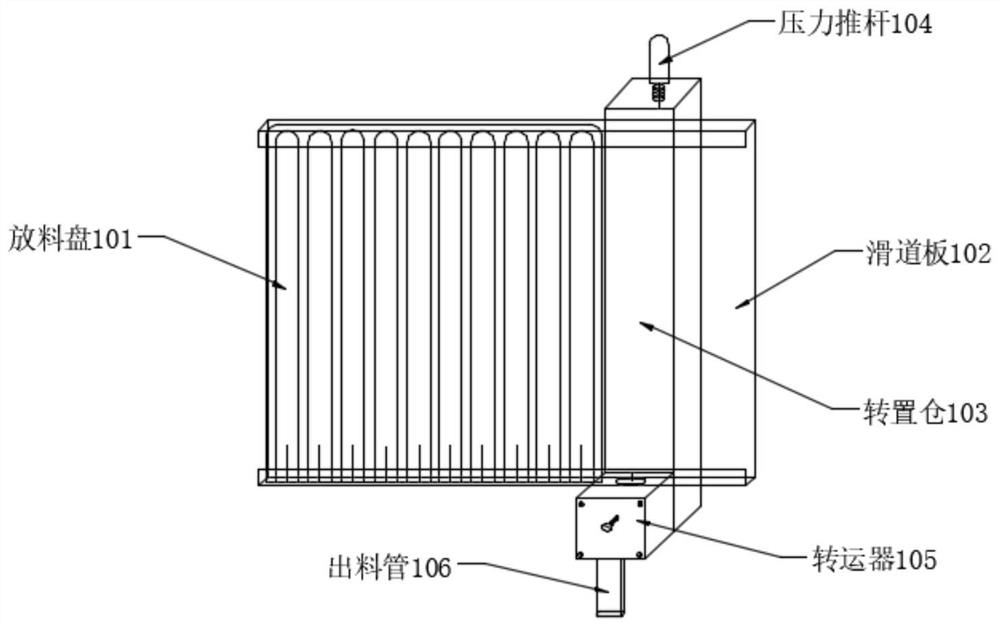

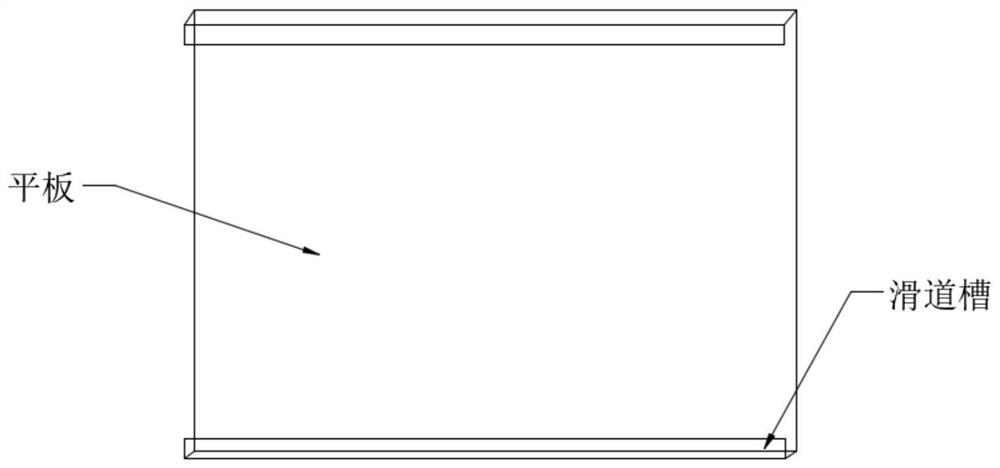

[0037] Such as figure 1 As shown, an embodiment of the present application provides a component delivery device, which includes: a discharge tray 101, a slideway plate 102, a pressure push rod 104, a transfer device 105 and a discharge pipe 106, wherein,

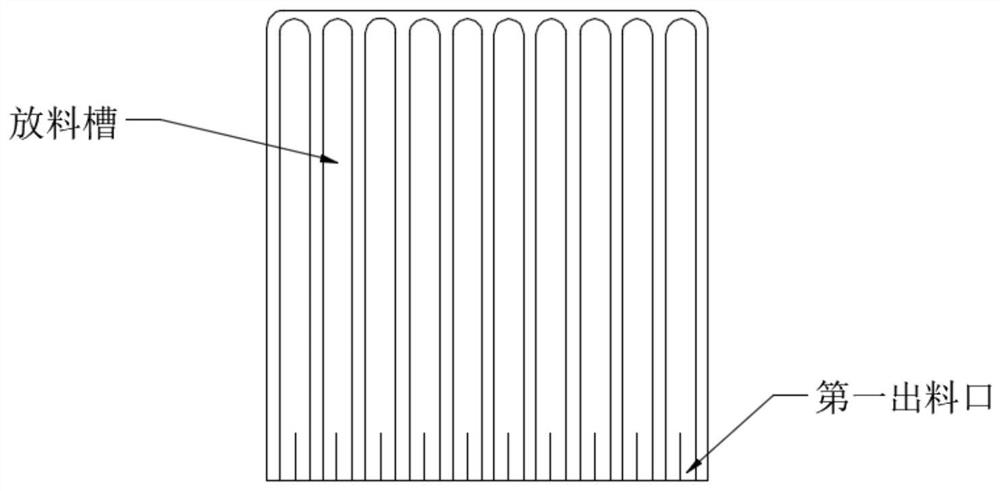

[0038] Such as figure 2 As shown, the discharge tray 101 is arranged on the slideway plate 102, and the discharge tray includes a plurality of mutually independent discharge troughs and a first outlet corresponding to the discharge troughs ( figure 2 shown in ), wherein, the discharge trough is used to store the components; the first outlet is used to transfer the components to the transfer device, it should be noted that the discharge tray 101 can be Disassembly, in the actual operation, you can prepare multiple discharge trays that store components with transmission. After the components of one discharge tray are transferred, you can directly replace them with another stored discharge tray, which is convenient. Rapid r...

Embodiment 2

[0052] Such as Figure 6 As shown, another embodiment of the present application provides a method for transferring components using the device described in Embodiment 1, the method comprising:

[0053] S10. Slide the discharging tray storing components to the notch position of the slideway plate;

[0054] S20. When the pressure push rod is in the first state, press down the pressure push rod to drive the transfer device to move from the initial position to transfer a component into the discharge pipe; when the pressure push rod is in the second state, Release the pressure push rod to drive the transfer device back to its original position and introduce the next component.

[0055] It should be noted that the first state is when the pressure push rod is pressed down, and the second state is when the pressure push rod is released. The above methods and steps can realize process production through automation of machinery and equipment, which should be understood by those skill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com