A kind of mixing machine for alloy pc composite material

A composite material and mixer technology, applied in the field of PC composite materials, can solve the problems of safety, financial and material damage, insufficient mixing, material impact, etc., and achieve the effects of convenient operation, simple structure, convenient and efficient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

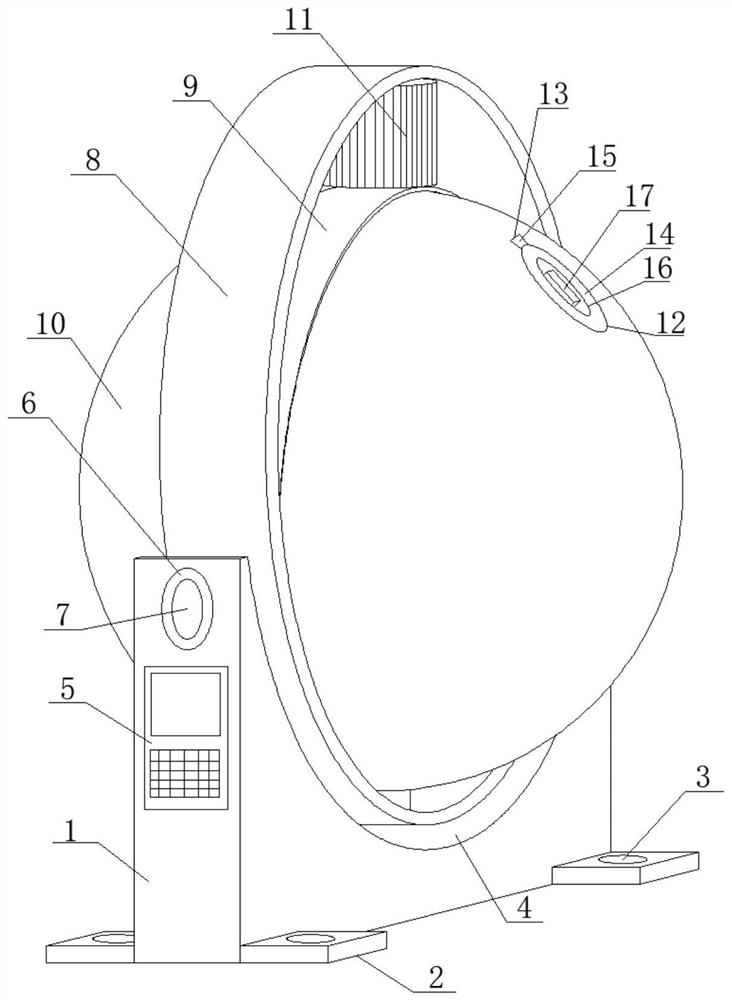

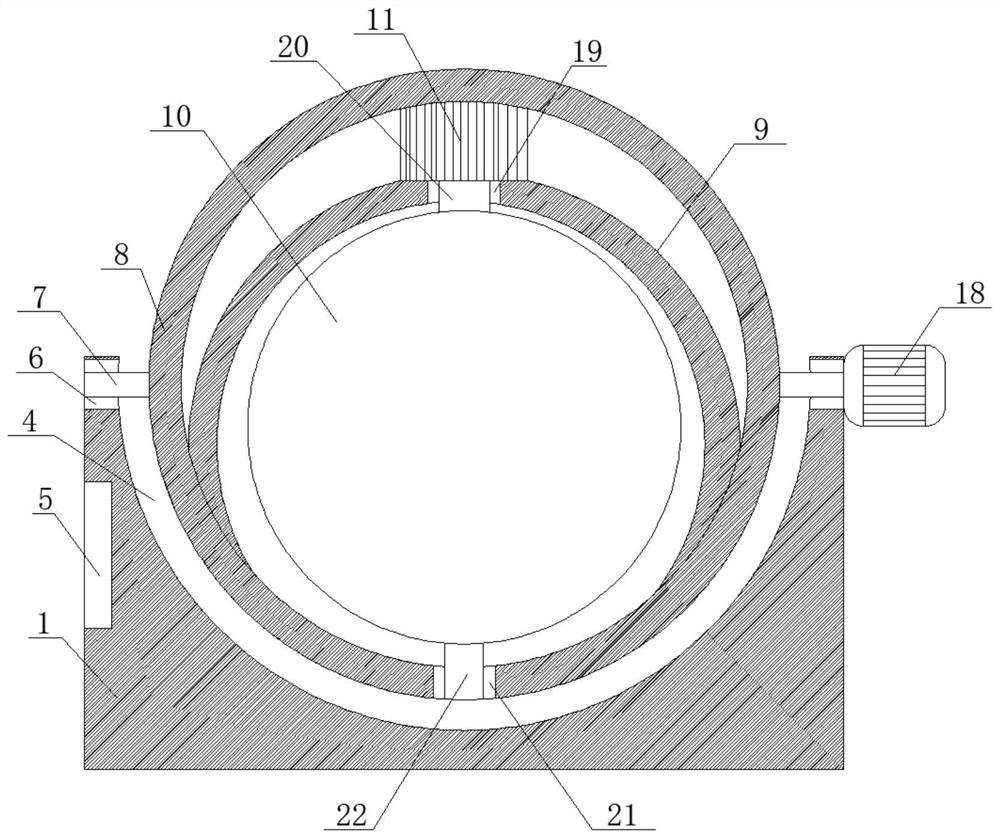

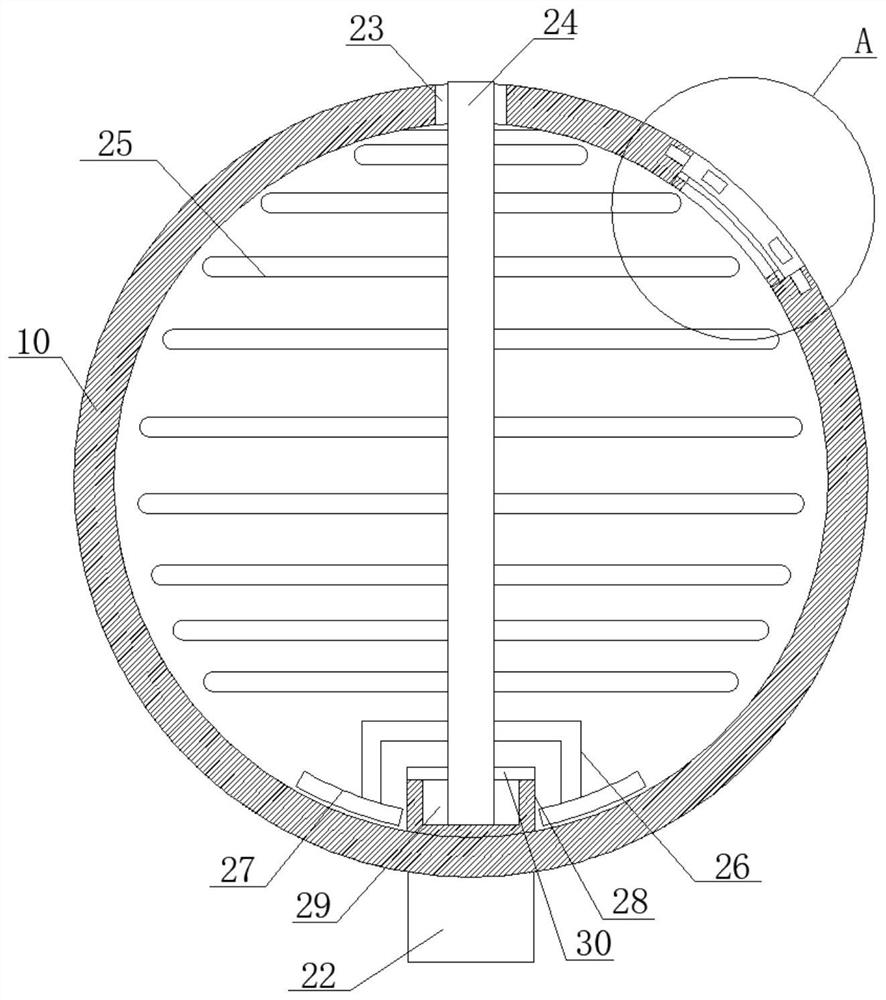

[0027] see Figure 1-2 , in an embodiment of the present invention, a compounding machine for alloy PC composite materials includes a support base 1, a fixed plate 2 is welded symmetrically and horizontally on both sides of the support base 1, and a connecting through hole 3 is opened on the top surface of the fixed plate 2 , the number of fixed plates 2 is several pieces, and a plurality of fixed plates 2 are arranged symmetrically and horizontally on both sides of the support base 1 close to the bottom surface, and the bottom surface of the fixed plate 2 and the bottom surface of the support base 1 are kept on the same horizontal plane. The connecting through hole 3 runs through the top surface of the fixed plate 2 and extends to the bottom surface. The top surface of the support base 1 is horizontally provided with an overturn groove 4. The overturn groove 4 is horizontally opened at the center of the top surface of the support base 1. The shaped opening is arranged upwards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com