Environment-friendly wood dyeing method

A dyeing method and wood technology, applied in the field of wood dyeing, can solve the problems of polluted environment, peculiar smell of chemical dyes, easy fading, etc., and achieve the effect of natural color and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Red oak, density is 700kg / cubic, dyed with red dye.

[0032]The formula of red dye: safflower + madder + hematoxylin + vinegar + water, the mass ratio is 1:1:1:3:10.

[0033]The preparation of the red dye: direct extraction and boiling with water to make the juice. Specifically: according to the above formula, safflower, madder, and hematoxylin are crushed, mixed with vinegar and water, and the water temperature is controlled at 50°C for 3 hours, then the impurities are filtered out and concentrated to obtain the red dye.

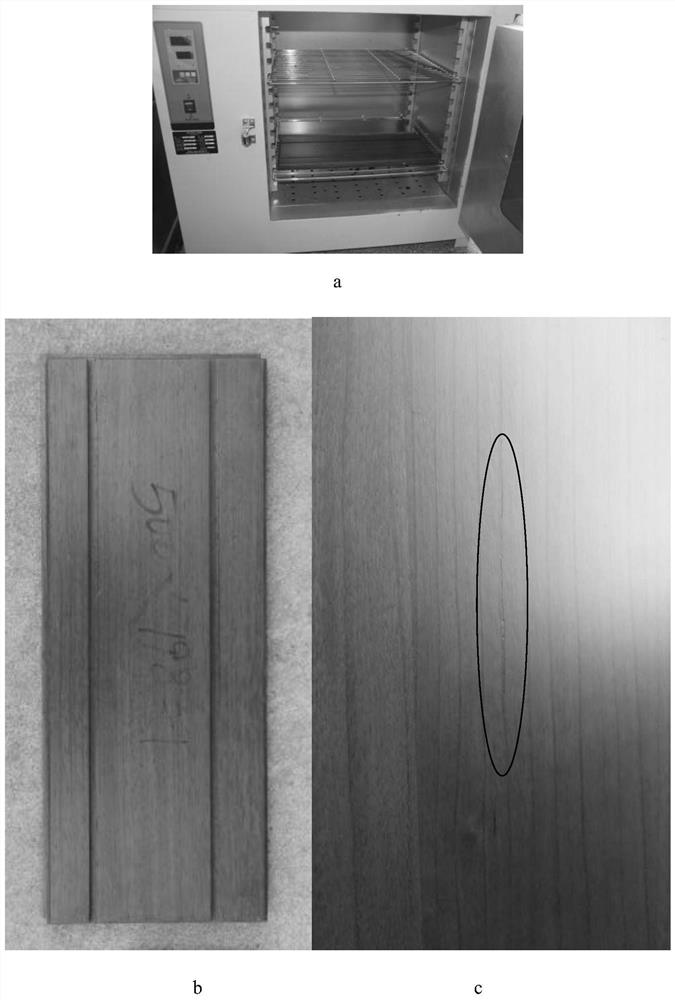

[0034]Dyeing: After immersing the red oak in the red dye for 8 hours, take it out, wipe off the remaining liquid on the surface, and place it in ventilated air for 24 hours to check whether the surface of the wood is dry without obvious dampness. If it is obviously dry, the dyeing process is completed, and the dyeing effect is as followsFigure 5As shown in a, subsequent processing can be carried out.

Embodiment 2

[0036]New Zealand pine has a density of 500kg / cubic and is dyed with yellow dye.

[0037]The formula of the yellow dye: Sorrel grass + Sophora japonicus + vinegar + ethanol + water, the mass ratio is 1:0.8:3:10:5.

[0038]Preparation of red dye: vinegar, ethanol and water are evenly mixed and then divided into three equal parts; according to the above formula, crush the chervil and sophora japonica, put them in a closed container, pour the first part of vinegar, ethanol and After immersing in water for 24 hours, pour out the immersion liquid; then immerse the immersion liquid with a second portion of vinegar, ethanol and water for 6 hours, and pour out the immersion liquid. Repeat for a total of two times; finally, after mixing the above three immersion liquids, Filter out impurities and concentrate to obtain yellow dye.

[0039]Dyeing: Take out the New Zealand pine wood after immersing it in yellow dye for 5 hours. Wipe off the surface residue. After placing it in ventilated air for 24 hour...

Embodiment 3

[0041]Big-leaf red sandalwood, density is 500kg / cubic, dyed with blue dye.

[0042]The formula of the blue dye: horse blue + wood blue + isatis blue + vinegar + ethanol + water, the mass ratio is 1:1:0.8:3:12:5.

[0043]Preparation of blue dye: vinegar, ethanol and water are evenly mixed and divided into three equal parts; according to the above formula, pulverize horse blue, wood blue, and isatis, put them in a closed container, and pour the first part of food. After immersing in vinegar, ethanol and water for 24 hours, pour out the soaking liquid; then soak the soaking liquid with the second portion of vinegar, ethanol and water for 6 hours, pour out the soaking liquid, and repeat twice; finally, the above three soaking After the liquid is mixed, the impurities are filtered out and concentrated to obtain the blue dye.

[0044]Dyeing: Immerse the large-leaf red sandalwood wood in blue dye for 10 hours and then take it out. Wipe off the surface residue. After placing it in ventilated air for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com