Numerically-controlled machine tool stable in use and high in precision

A CNC machine tool, high-precision technology, applied in the direction of metal processing machinery parts, maintenance and safety accessories, drilling/drilling equipment, etc., can solve problems affecting normal production, parts inspection, a large number of defective products, etc., to reduce The effect of capturing difficulty, increasing willfulness, and reducing cleaning intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

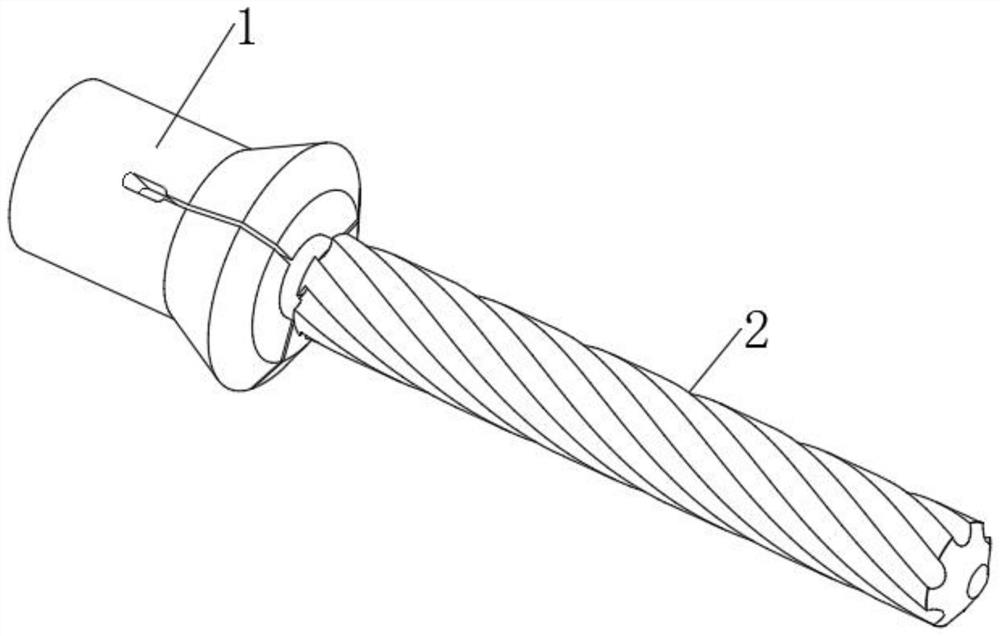

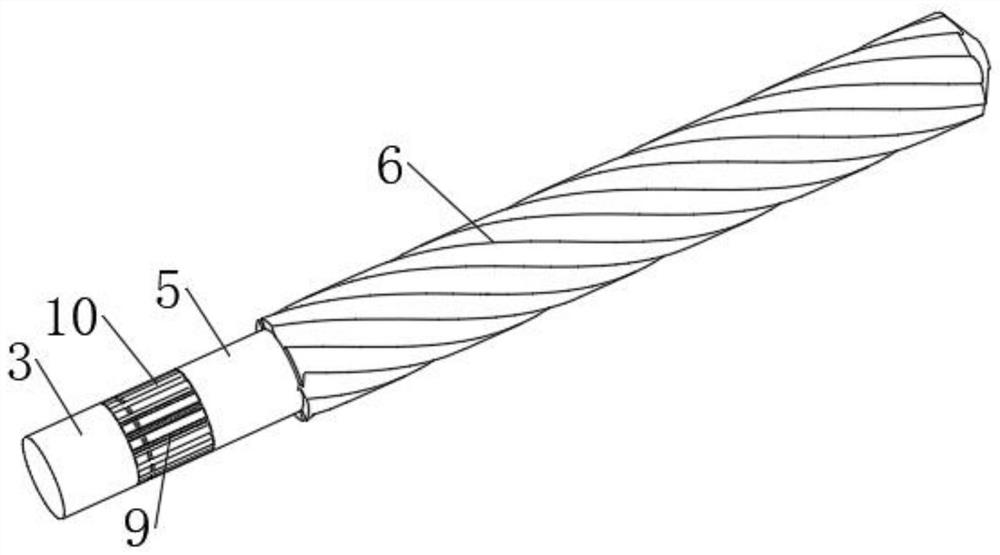

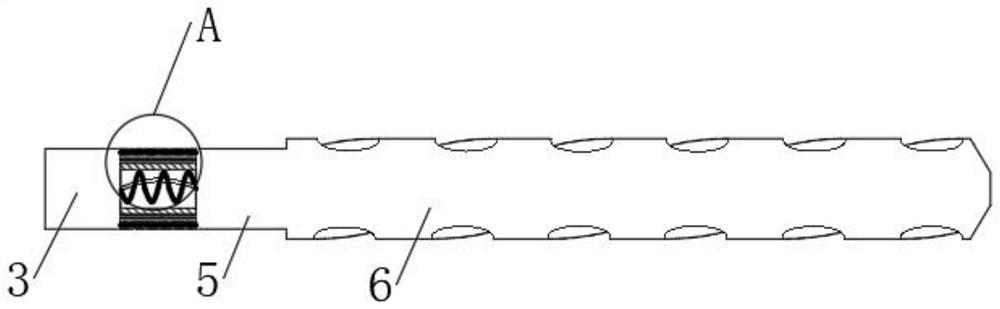

[0033] see Figure 1-5, a CNC machine tool with stable use and high precision, including a tool seat 1, a high-precision drill bit 2 matching itself is inserted into the tool seat 1, the high-precision drill bit 2 includes a fixed end 3, and the high-precision drill bit 2 passes through the fixed end 3 is fixedly connected with the knife seat 1, the end of the fixed end 3 far away from the knife seat 1 is fixedly connected with the connecting pipe 4, the end of the connecting pipe 4 far away from the fixed end 3 is fixedly connected with the connecting pipe 4, and the end of the connecting part 5 far away from the connecting pipe 4 is fixed The drill body 6 is connected, and most of the fixed end 3, the connecting pipe 4 and the connecting part 5 are inserted into the tool holder 1, and a plurality of reinforcement piles 10 are arranged on the outside of the connection pipe 4, and the two ends of the reinforcement pile 10 are respectively connected with the The fixed end 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com