Industrial contaminated soil remediation device

A soil remediation and industrial technology, applied in the field of soil pollution, can solve problems such as poor remediation effect, too little remediation solution, normal road damage, etc., and achieve the effects of convenient laying, increased applicability, and damage prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

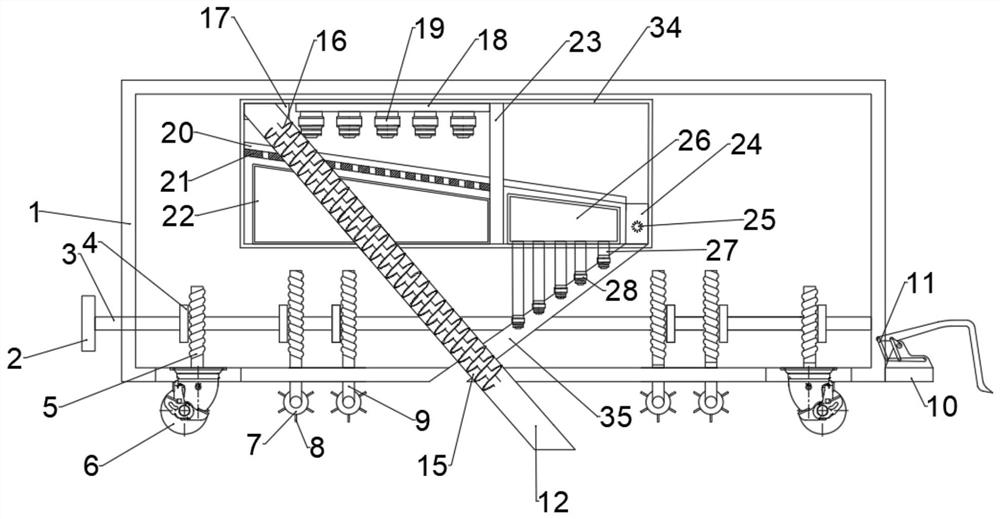

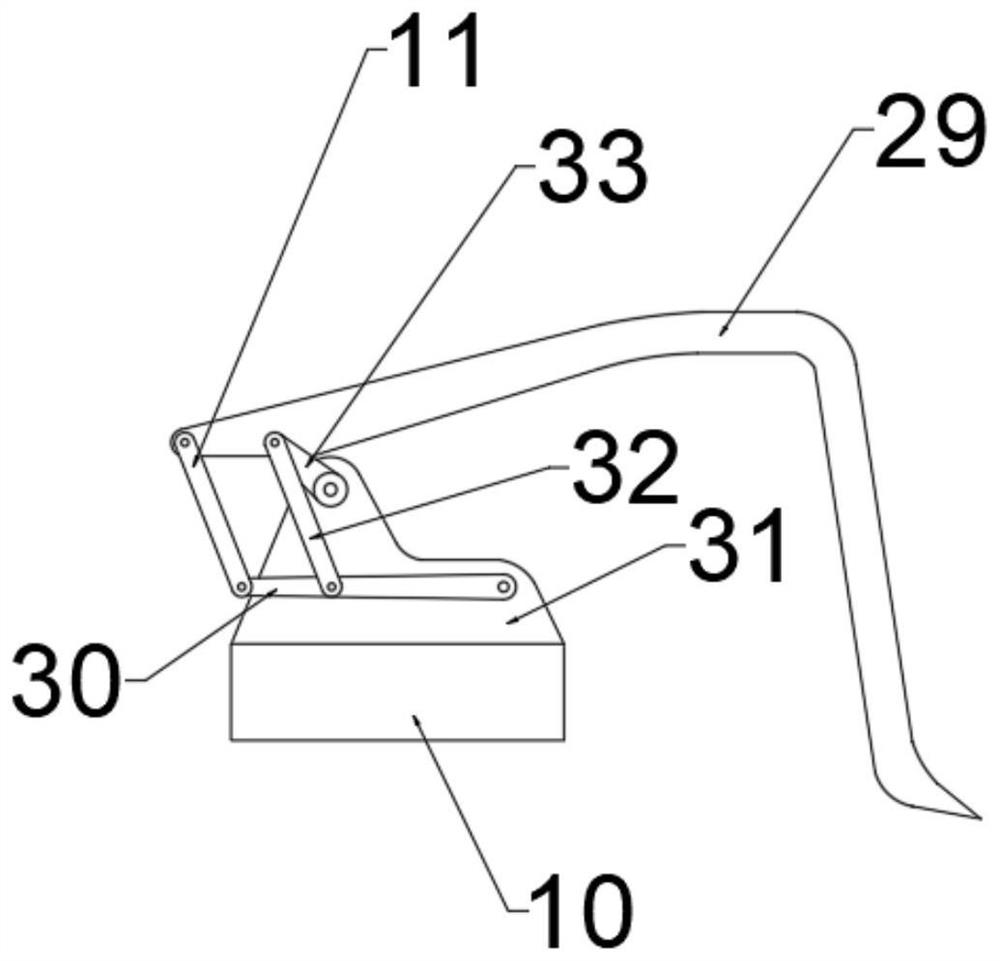

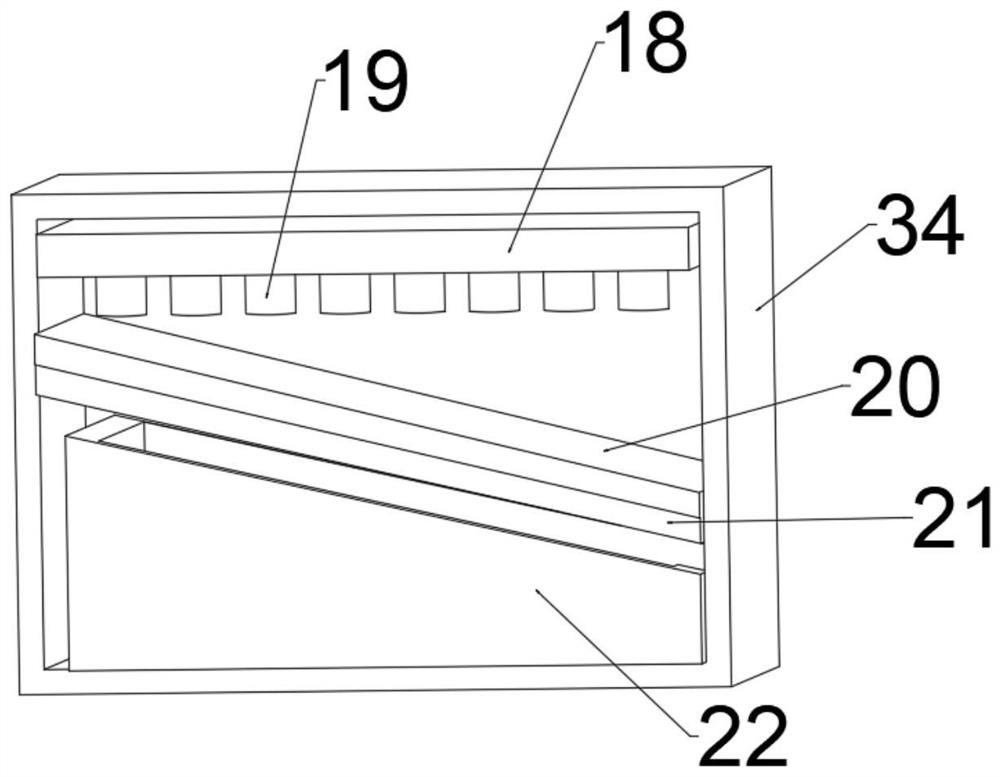

[0030] refer to Figure 1 ~ Figure 3, a soil remediation device for industrial pollution, comprising a box body 1, the lower right side of the box body 1 is connected with a fixed platform 10 by bolts, the upper side of the fixed platform 10 is connected with a fixed block 31 by bolts, and the right side of the fixed block 31 shell wall is rotatably connected with a The second connecting rod 30, the left end of the second connecting rod 30 is connected with the first connecting rod 11, and the end of the first connecting rod 11 away from the second connecting rod 30 is connected with the turning block 29, the middle part of the second connecting rod 30 A third connecting rod 32 is rotatably connected, and an end of the third connecting rod 32 away from the second connecting rod 30 is rotatably connected with a fourth connecting rod 33, and the fourth connecting rod 33 is rotatably connected with the shell wall top of the fixed block 31, and the earth block 29 and the top of th...

Embodiment 2

[0038] refer to Figure 4 , a kind of soil remediation device for industrial pollution. Compared with Embodiment 1, the present embodiment has a sliding rod 13 that is rotatably connected to the bucket 12, and a chute 14 is provided on the shell wall of the box body 1. The sliding rod 13 and the chute 14 is slidingly connected, and the left and right ends of the chute 14 are provided with draw-in grooves. When the soil does not need to be repaired, the sliding rod 13 is slid in the chute 14, so that the bucket 12 is lifted to prevent damage to the normal soil, and Utilizing the slot, when the sliding rod 13 reaches the left and right ends of the sliding groove 14, the position of the sliding rod 13 is limited to increase its applicability.

[0039] Working principle: When the soil does not need to be repaired, slide the sliding rod 13 in the chute 14 to lift the bucket 12 to prevent damage to the normal soil, and use the slot to make the sliding rod 13 reach the chute 14 At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com