Water purification system and process

A sewage and fresh water technology, applied in the direction of water conservation, energy waste water treatment, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Reference to one or more figures that reference a component does not imply that the component is only visible in those figures. To avoid redundant reference numerals, some visible components may not be numbered in all figures.

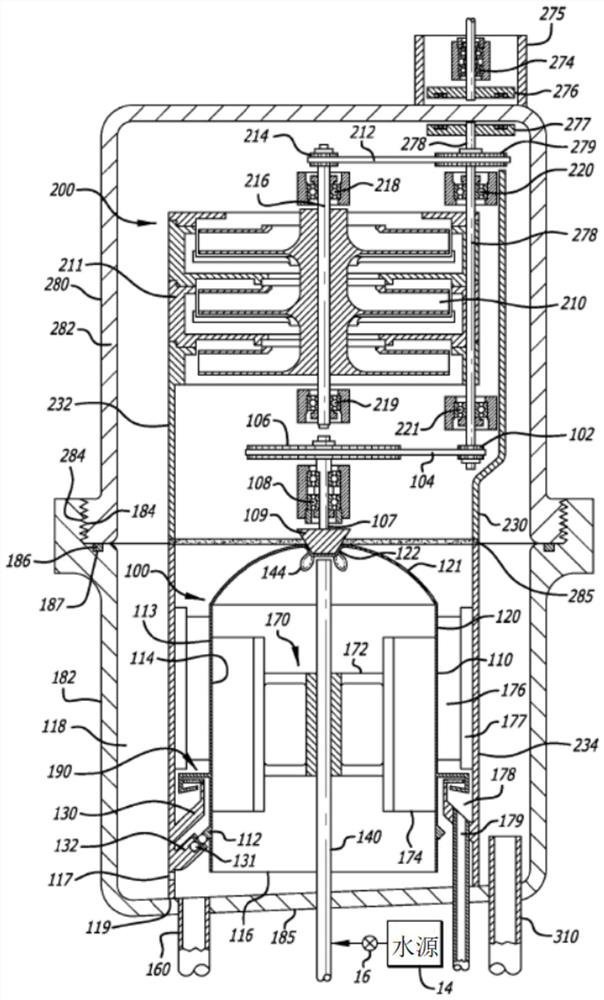

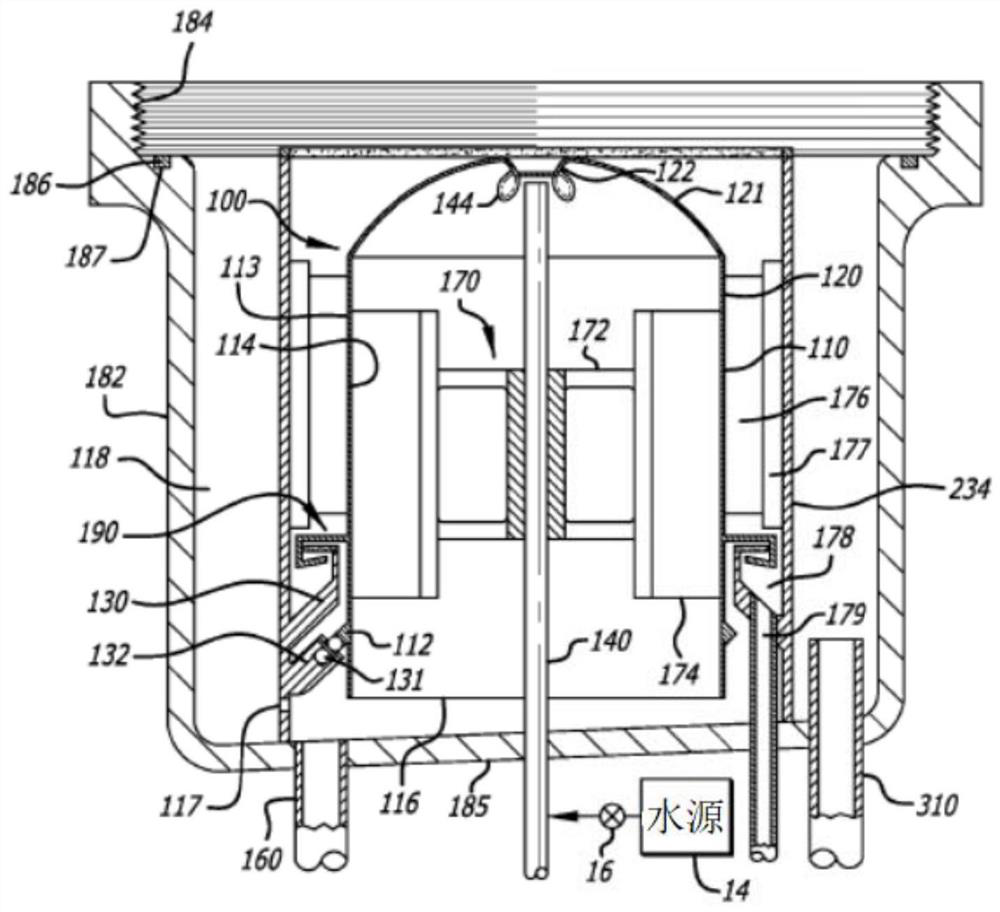

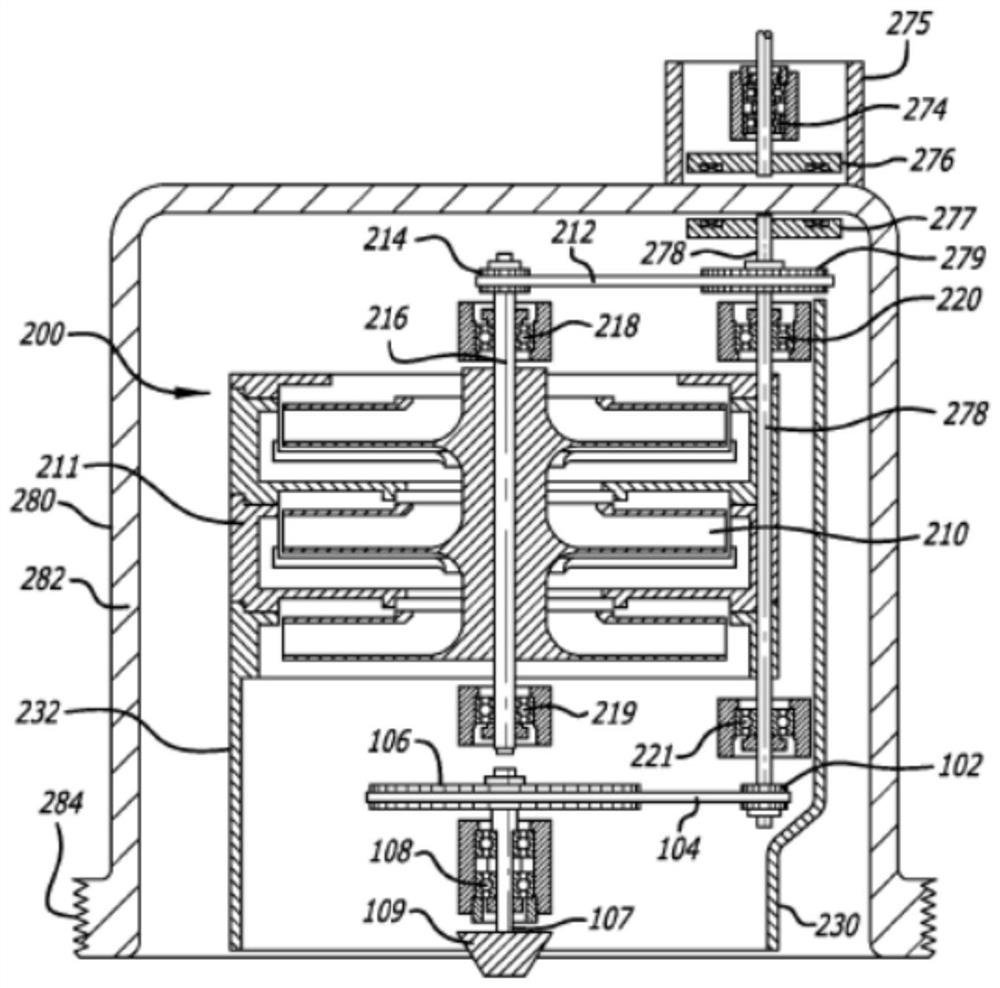

[0069] Figure 1-9 Boiler-condenser and blower-compressor units for: figure 1 The water purification system 10 has two main components: (a) boiler condenser unit 100 and (b) blower or compressor unit 200 . Please refer to figure 1 , 2 , 3 and 6. The two devices can be mounted side by side or as figure 1 As shown, placed on top of each other in a common housing. Placing these components side-by-side and connected by pipes or other channels may result in heat loss and pressure drop as steam moves between components, but may provide better access to internal parts. However, having the components in the same enclosure should reduce heat loss and pressure drop. References in the application to "housing" means a single housing or multiple hous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com