Unified supervision method and system for construction quality based on Internet of Things technology

An Internet of Things technology and construction quality technology, applied in the field of nuclear power plant construction quality supervision, can solve problems such as complicated procedures, fraudulent inspectors, and many paper documents, and achieve the effect of avoiding storage confusion, avoiding missed inspections, and being easy to call

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

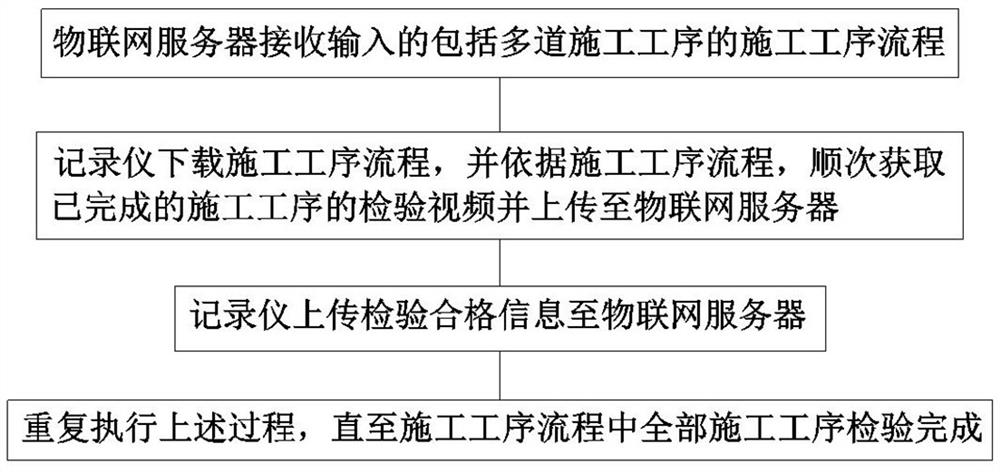

[0030] A method for unified supervision of construction quality based on Internet of Things technology, comprising the following steps: Step 1: The Internet of Things server receives and inputs the construction process flow including multiple construction processes;

[0031] Step 2: The recorder downloads the construction process flow from the IoT server, and according to the construction process flow, sequentially obtains the inspection videos of the completed construction processes and uploads them to the IoT server;

[0032] Step 3: The recorder uploads the received inspection qualified information to the IoT server;

[0033] Step 4: Repeat steps 2 and 3 until all construction process inspections in the construction process flow are completed.

[0034] Wherein, the first step also includes the following steps: Step 1-1: the Internet of Things server receives the input data of multiple inspection nodes; the inspection nodes correspond to the construction process one by one. ...

Embodiment 2

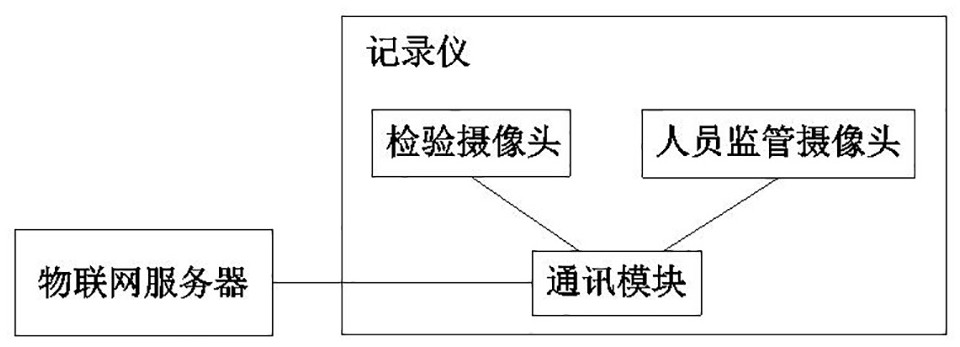

[0042] A construction quality unified supervision system based on Internet of Things technology, including: Internet of Things server and recorder. The Internet of Things server is used to store the construction process flow, and the construction process flow includes multiple construction processes. The data of multiple inspection nodes is also stored in the server of the Internet of Things, and the inspection nodes correspond to the construction process one by one. The recorder includes an inspection camera for obtaining inspection videos corresponding to the construction process. The recorder also includes a personnel supervision camera for obtaining personnel supervision videos. The recorder also includes a camera for uploading inspection videos and personnel supervision videos to the IoT server. The communication module of the verification node.

[0043] In actual operation, the management personnel input the construction process flow including multiple construction proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com