Automatic detection device for brake disc

An automatic detection device and brake disc technology, applied in the direction of measuring devices, vehicle testing, mechanical parts testing, etc., can solve the problems of single detection content and inability to detect the thermal working state data of brake discs, etc., to achieve comprehensive detection content, data Authentic, reliable and highly referential effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

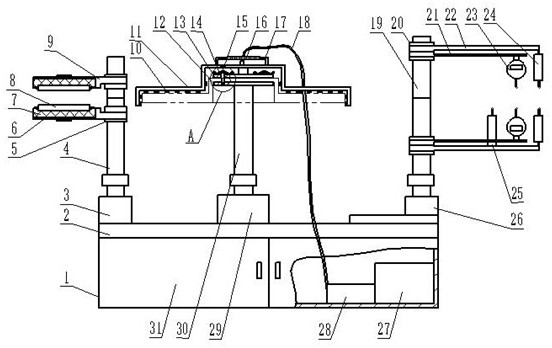

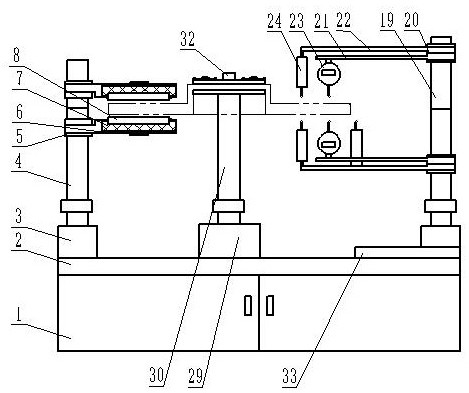

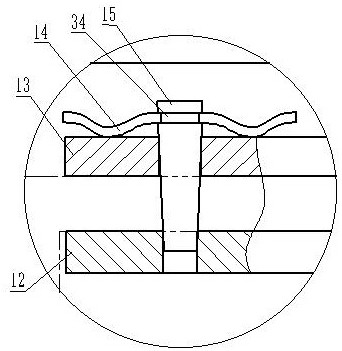

[0020] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0021] As shown in the drawings, the whole includes a basic unit, a heating unit, a detection unit and a control unit. The basic unit includes a box body 1, a workbench 2, a gear motor 3 29, a rotating shaft 30 and a gland 13. The box body 1 is installed on the workbench. 2, the box body 1 is connected with an openable box door 31 through a hinge, the reduction motor 29 is installed above the workbench 2, the rotating shaft 30 and the reduction motor 29 are connected through a coupling three, and the top of the rotating shaft 30 is integrated Tray 12, in order to quickly install the brake disc, the tray 12 is processed with a number of through holes 1, and the position of the through hole 1 corresponds to the position of the brake disc installation hole, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com