Switch cabinet dolly contact overtravel measuring device

A measuring device and switchgear technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of inaccurate measurement, cumbersome measurement work, heat explosion, etc., and achieve convenient operation, stable and accurate measurement data, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

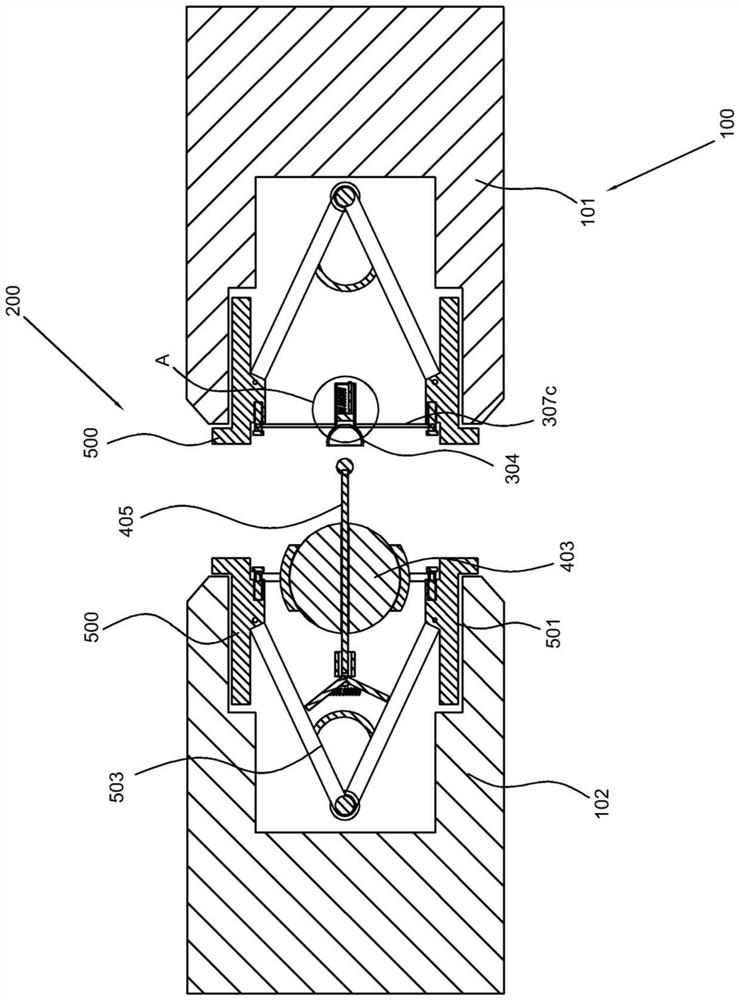

[0030] refer to Figure 1-Figure 3 , a switchgear trolley contact overtravel measuring device, including a measuring component 100, including a switchgear static contact 101, a switchgear trolley, and a moving contact 102 arranged at the front end of the switchgear trolley; and, cooperating with the detection component 200, It includes a measuring part 300 arranged on the static contact 101 and a connecting part 400 arranged on the front end of the moving contact 102 .

[0031] Specifically, the main structure of the present invention includes a measuring assembly 100. In this embodiment, the measuring assembly 100 includes a switchgear static contact 101. The static contact 101 of the switchgear is generally arranged inside the switchgear, and generally the static contact 101 There are several, set side by side in the switch cabinet, and then in order to be able to detect, there is also a switch cabinet trolley, the switch cabinet trolley is set separately from the switch cab...

Embodiment 2

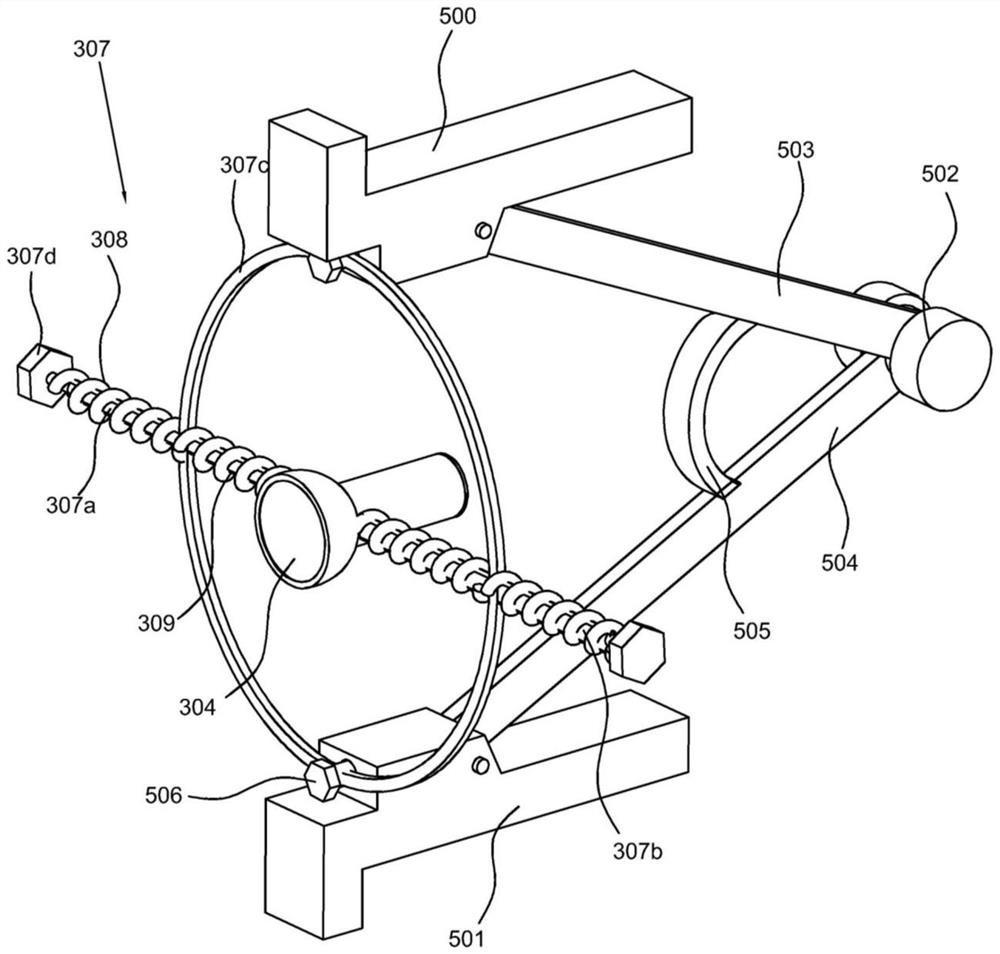

[0035] refer to Figure 1-Figure 5 , This embodiment is different from the first embodiment in that: the measuring part 300 includes a measuring piston 302 cavity 301 arranged on the static contact 101, a piston 302 slidingly connected in the measuring piston 302 cavity 301 and a piston 302 arranged on the piston The measuring ruler 303 on the 302, the front end of the measuring piston 302 cavity 301 is provided with a guide ring 304, the piston 302 and the measuring piston 302 cavity 301 are provided with a return spring 305, and the measuring piston 302 cavity 301 is provided with a The locking member 306, wherein, the outside of the measuring piston 302 cavity 301 is provided with an adjusting part 307, and the adjusting part 307 includes a first screw 307a and a second screw 307b connected to the side wall of the measuring piston 302 cavity 301, and the measuring piston 302 An elastic coil spring 307c is connected to the outside of the cavity 301, the first screw rod 307a ...

Embodiment 3

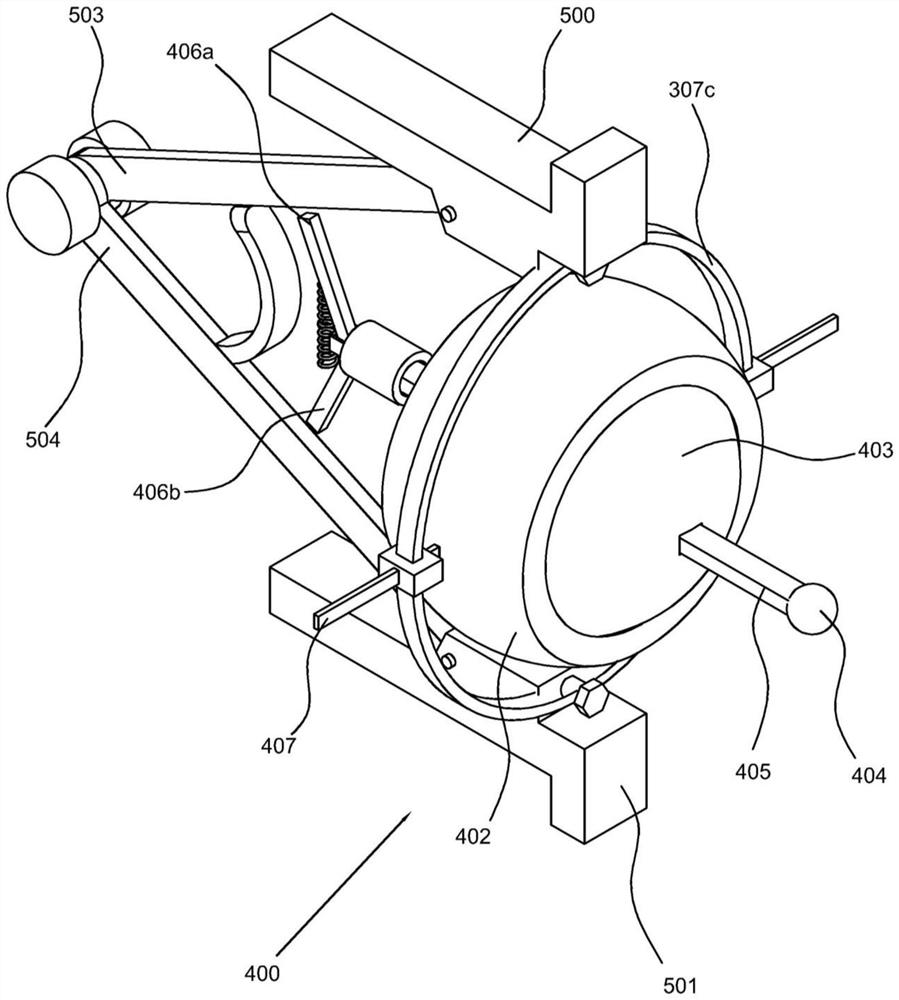

[0045] refer to Figure 2-Figure 6 , This embodiment is different from the above embodiments in that: the connecting part 400 includes a first positioning piece 500 and a second positioning piece 501 which are also arranged on the movable joint and an elastic coil spring 307c, and the elastic coil spring 307c is far away from the first positioning piece 500 and the second positioning member 501 are connected with a square guide bar 407, the movable joint is provided with a semi-hollow sphere 402 connected with the square guide bar 407, the semi-hollow sphere 402 is provided with a sphere 403, and the sphere 403 protrudes outwards. Measuring ball 404, a measuring rod 405 is threaded on the sphere 403, the measuring ball 404 is threadedly connected to the front end of the measuring rod 405, the rear end of the measuring rod 405 is connected with an adjustable limit piece 406, and the moving contact 102 is also hinged with a first splint 503 and the second splint 504, an adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com