Efficient liquefaction system of regenerative refrigerator adopting direct currents

A regenerative and refrigerator technology, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of high cost of helium collection and liquefaction, high cost of helium liquefaction, and large heat transfer resistance. Achieve the effect of small heat transfer resistance, improve liquefaction capacity and reduce thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

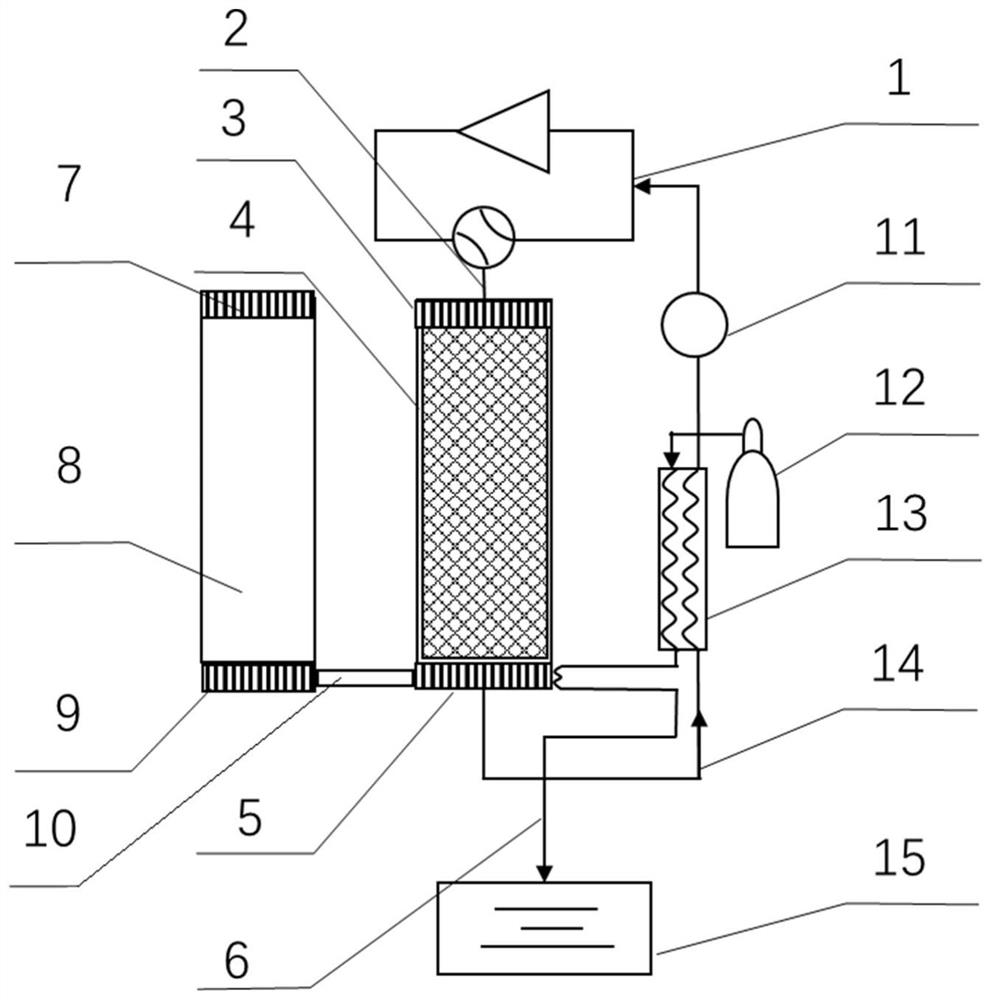

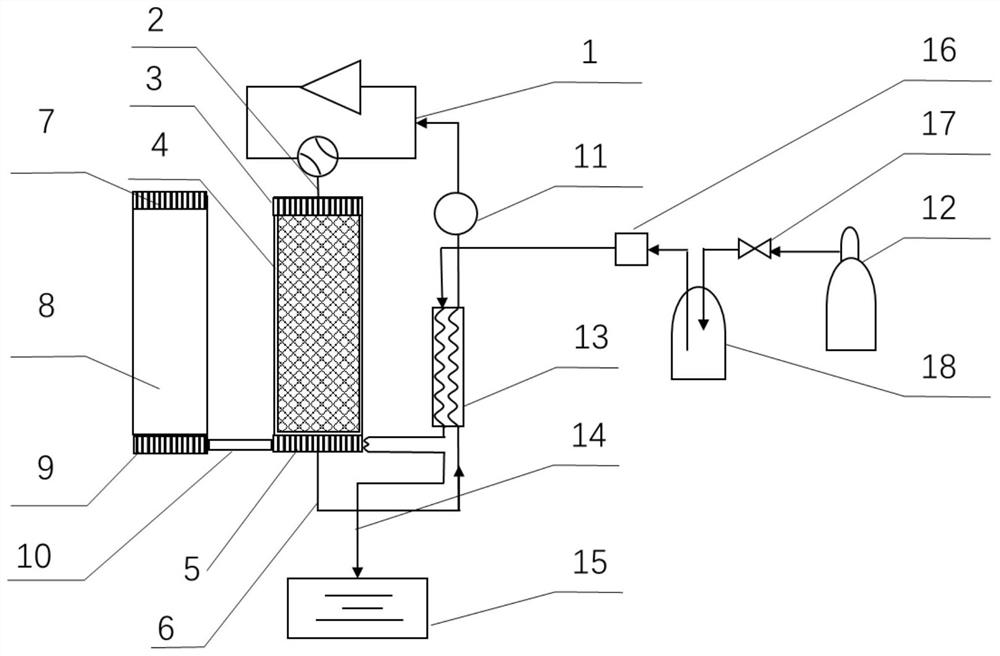

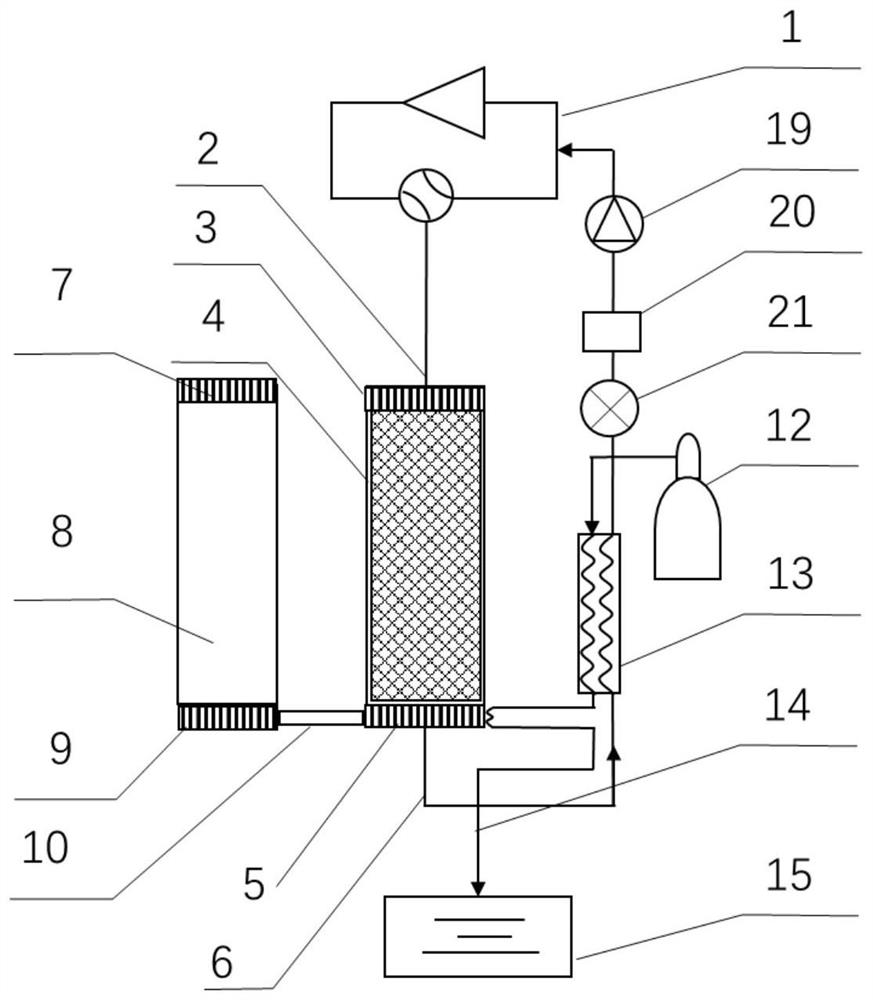

[0047] like figure 1 As shown, the high-efficiency liquefaction system using a direct current regenerative refrigerator in this embodiment includes a regenerative refrigeration module and a liquefaction module.

[0048] The regenerative cooling module consists of a regenerative chiller unit and a DC external circulation unit. The regenerative refrigerator unit includes compression device 1, compressor transfer pipe 2, regenerator hot end heat exchanger 3, regenerator 4, regenerator cold end heat exchanger 5, direct current circulation pipeline 6, expansion mechanism (eductor or vessel) hot end heat exchanger 7, expansion mechanism (eductor or vessel) 8, expansion mechanism (eductor or vessel) cold end heat exchanger 9, regenerator and expansion mechanism (eductor or vessel) transfer tube 10. The DC external circulation unit includes a DC outlet pipe 6 and a DC external circulation control assembly 11 .

[0049] The liquefaction module includes a high-pressure gas source 12 ...

Embodiment 2

[0059] like Figure 4 Shown, the GM type pulse tube refrigerator of embodiment 2 and two-way intake valve group, structure and figure 1 The structure of the refrigerator shown is basically the same, the difference is that the regenerative refrigerator is a GM pulse tube refrigerator, and the compression device 1 of the GM pulse tube refrigerator consists of a high pressure control valve 22, a low pressure control valve 23, a scroll compression Machine 24 is formed, and two-way intake valve group 25 is made up of two one-way valves antiparallel.

[0060] The connections between the components are:

[0061] The compression device 1 is connected by a scroll compressor 24, a high-pressure control valve 22 and a low-pressure control valve 23 through pipelines sequentially, the compressor transmission pipe 2, the heat exchanger 3 at the hot end of the regenerator, the regenerator 4, and the regenerator cold End heat exchanger 5, regenerator and expansion mechanism (vessel) transfe...

Embodiment 3

[0068] like Figure 5 Shown, the structural representation of the two-stage GM refrigerator of embodiment 3, structure and figure 1 The structure of the refrigerator shown is basically the same, the difference is that the regenerative refrigerator is a GM refrigerator, and the compression device 1 of the GM refrigerator consists of a piston compressor 27, a post-stage water cooler 28, a high-pressure balance tank 29, an air intake Valve 30, exhaust valve 31 and low-pressure balance tank 32; in addition, it is necessary to add a primary regenerator 33, a primary hot end device 34, a primary cylinder 35, a secondary cylinder 36 and a primary counterflow heat exchanger 37 .

[0069] The connections between the components are:

[0070]The compression device 1 is connected by pipelines sequentially by a piston compressor 27, a post-stage water cooler 28, a high-pressure balance tank 29, an intake valve 30, an exhaust valve 31, and a low-pressure balance tank 32. End heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com