Device capable of adjusting primary air injection flow velocity

A technology of flow velocity and secondary air, applied in the field of boilers, can solve the problems of affecting the combustion effect of pulverized coal and the inability of pulverized coal to be evenly distributed in the furnace, and achieve the effect of satisfying combustion requirements, uniform distribution and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

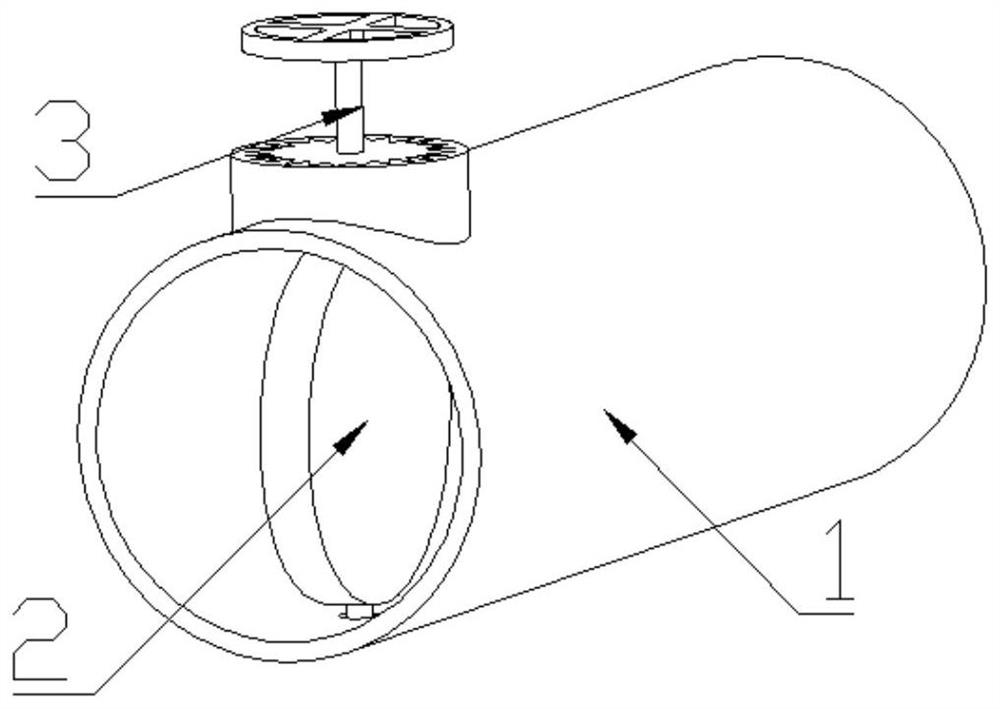

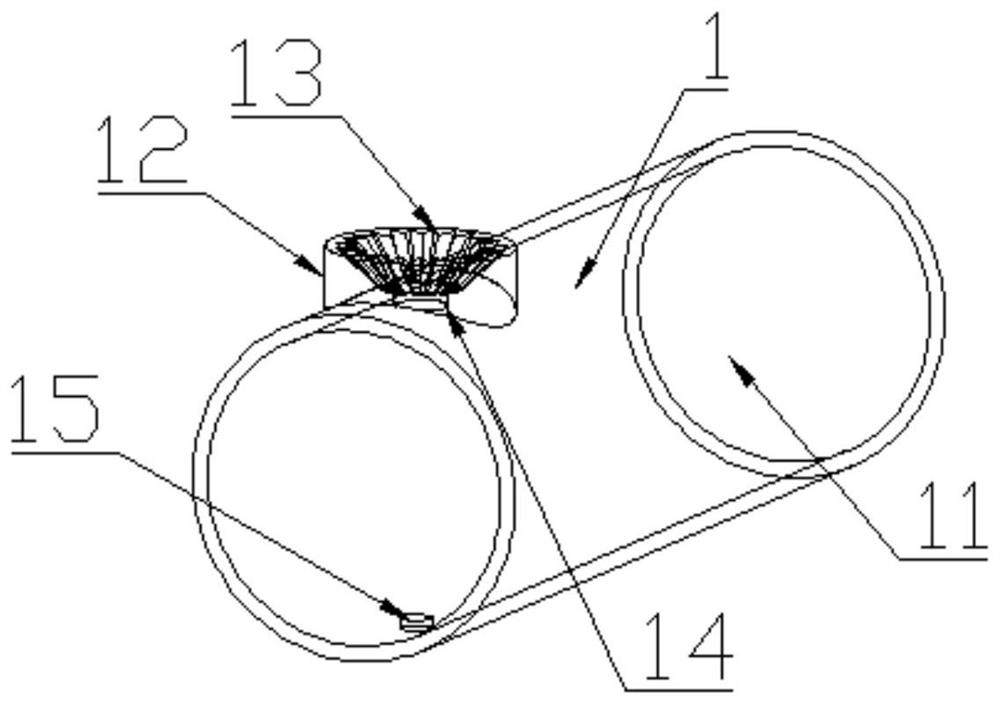

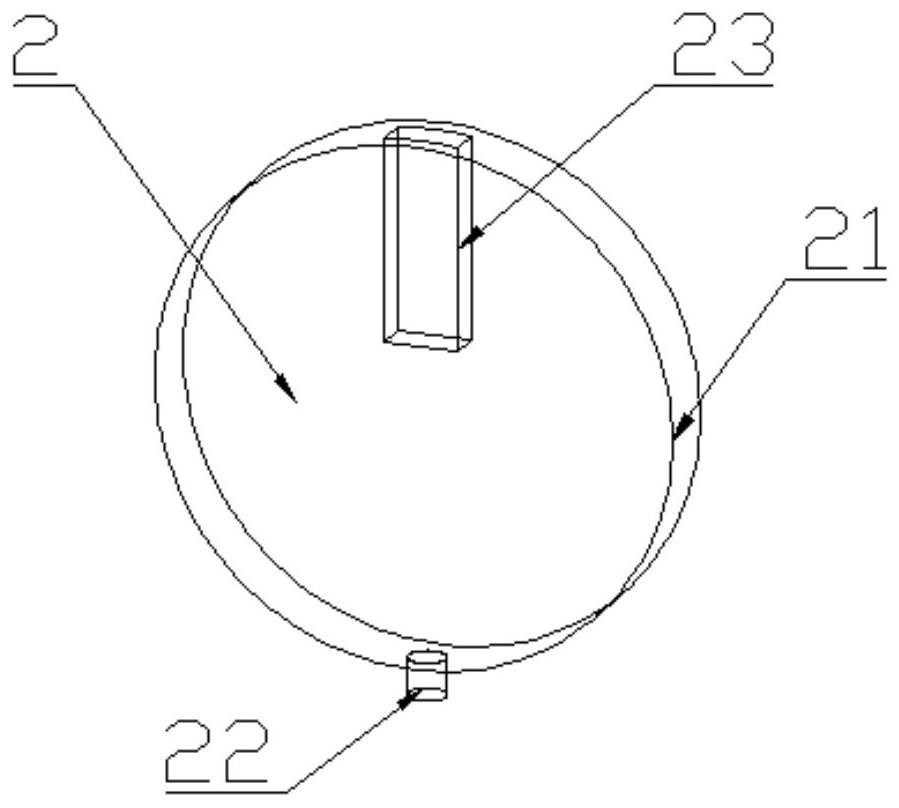

[0028] A device that can adjust the jet flow rate of primary air, including primary air duct 1, baffle plate 2 and adjustment handle 3; primary air duct 1 is provided with a circular straight pipe 11, a circular boss 12, and an inclined internal gear 13 , circular through hole 14 and positioning blind hole 15; baffle plate 2 is provided with circular plate 21, positioning cylinder 22 and groove 23; adjusting handle 3 is provided with connecting section 31, inclined external gear 32, cylindrical section 33 and Turn the handle 34; the baffle plate 2 is located at the positioning blind hole 14 in the primary air duct 1, and the connecting section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com