Construction process of mold-free concrete spraying beam

A construction technique and sprayed concrete technology, which is applied in basic structure engineering, sheet pile wall, excavation, etc., can solve the problems of poor slope applicability, complicated construction procedures, and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below in conjunction with accompanying drawing:

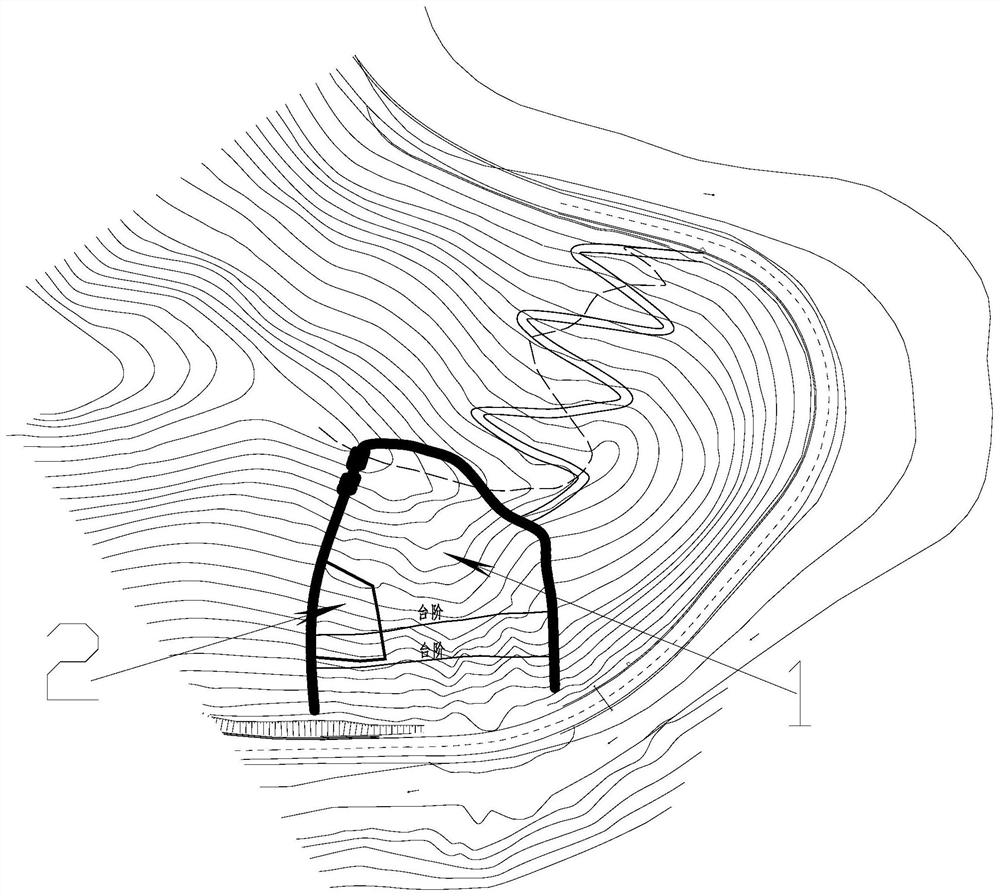

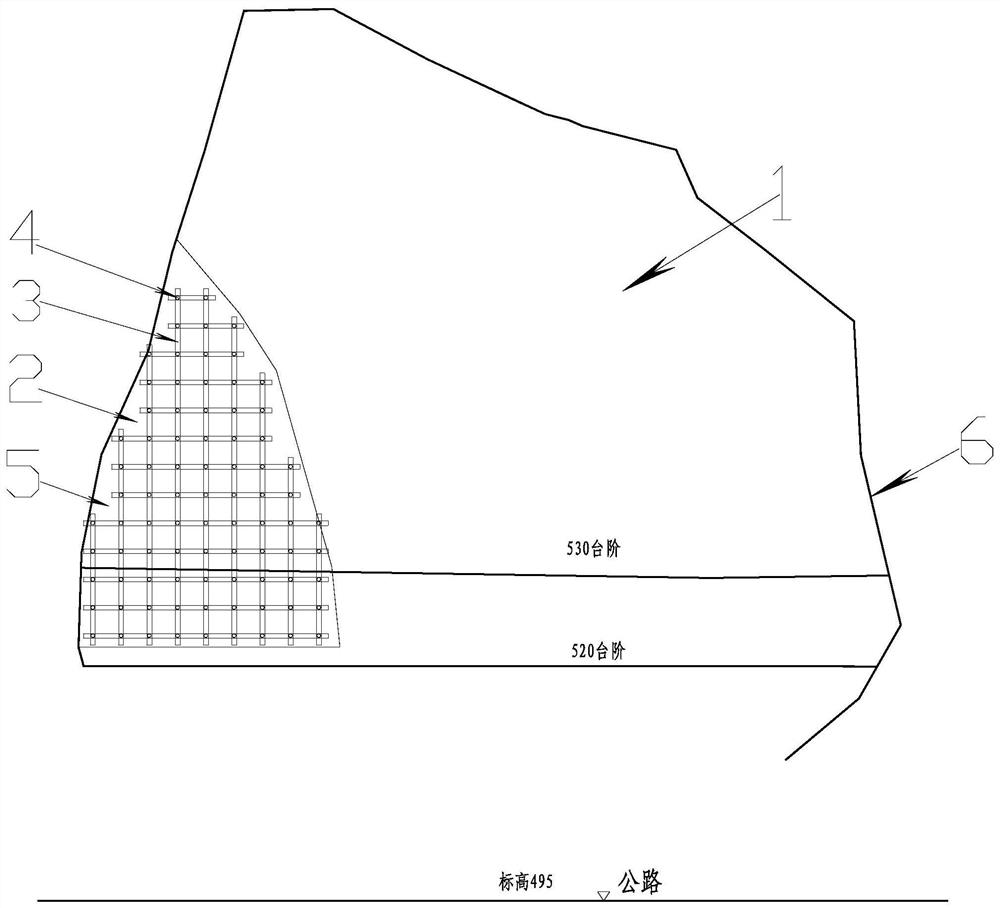

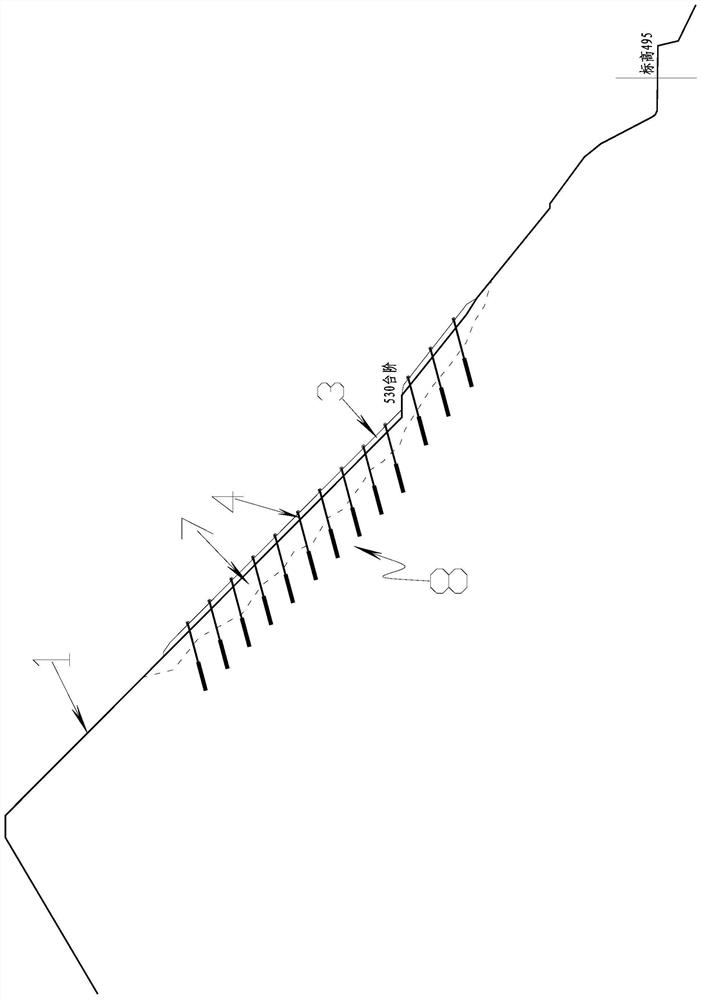

[0078] Refer to the attached picture: the upper part of the slope is an ancient landslide, with a volume of more than 40,000 cubic meters. There are many tension cracks on the slope, and a large number of loose rock masses are distributed on the slope. The design adopts the method of slope cutting and unloading + slope protection. After slope cutting, most of the rock mass on the slope surface is relatively complete. Conventional shotcrete or hanging active protection nets can be used for slope protection. The remaining parts of the slope on the local slope cannot be cut again, and the rock mass is relatively broken. Stress anchor + lattice beam reinforcement. The traditional reinforced concrete lattice beam needs vertical formwork and cast-in-place concrete. The design and construction technology of sprayed concrete lattice beams replacing cast-in-place lattice beams; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com