Hot air heating equipment based on thermal regeneration of old asphalt pavement

A technology of heating equipment and heat regeneration, applied in roads, roads, road repairs, etc., can solve problems such as safety hazards, adhesion at the air outlet, and easily damaged microwave heating components, so as to reduce safety hazards, speed up heating efficiency, Protect the effect that is not easy to be clogged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

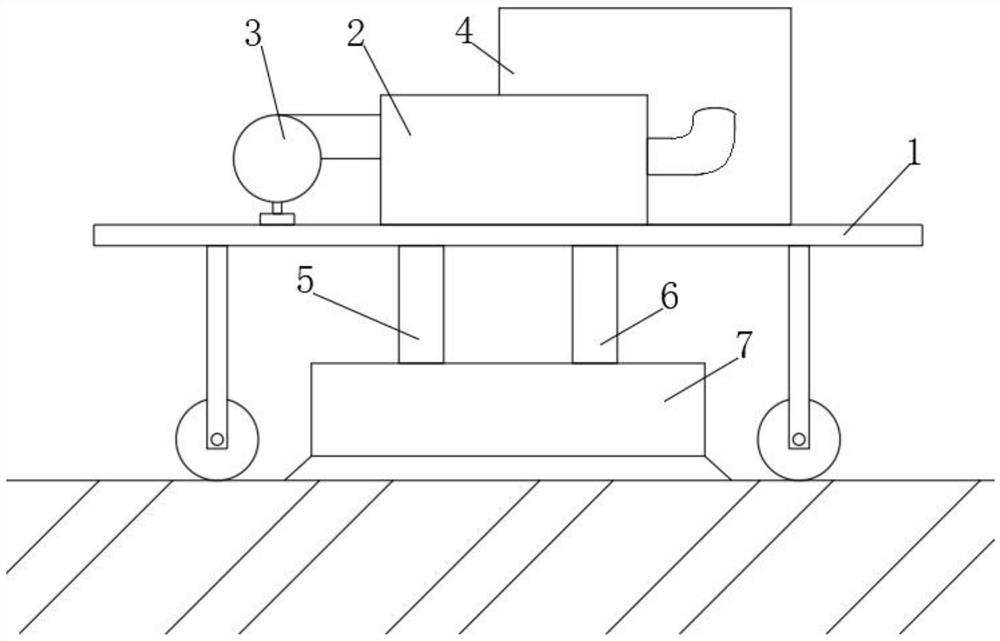

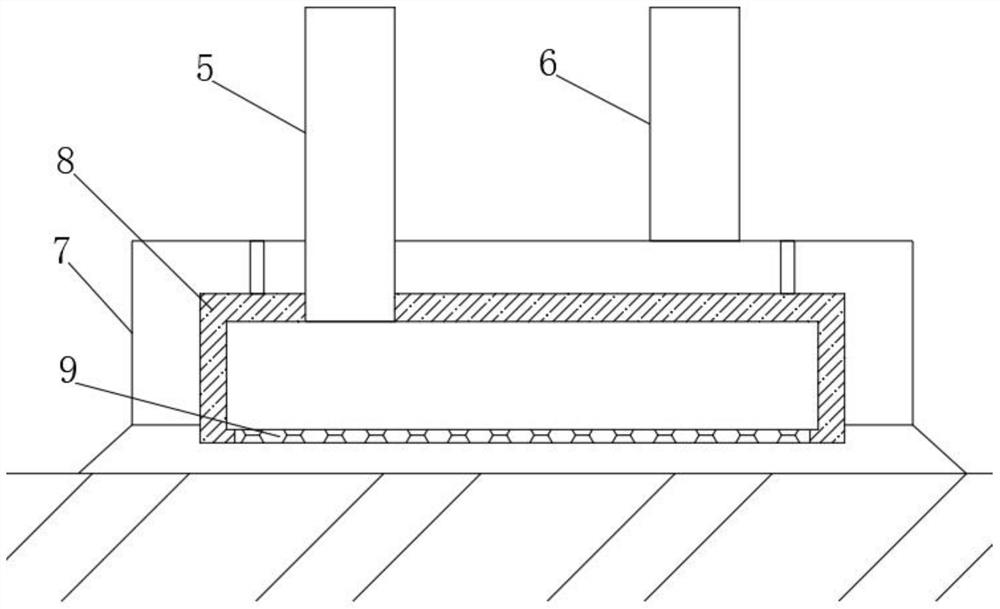

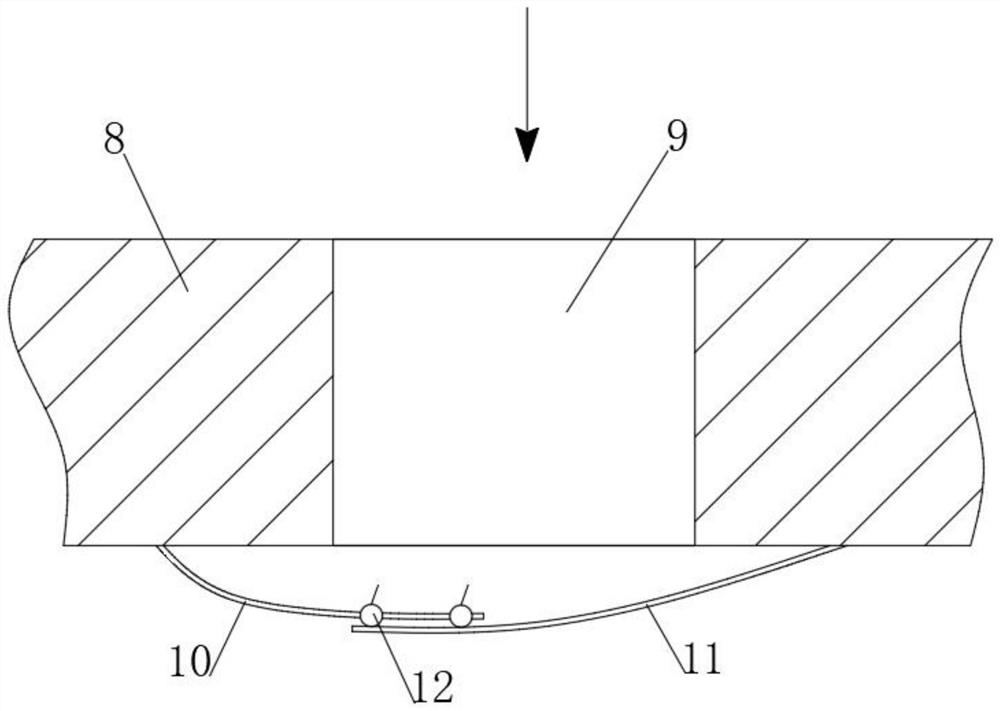

[0041] see Figure 1-2 , based on old asphalt pavement thermal regeneration hot air heating equipment, including chassis car 1, hot air circulation cylinder 2, blower 3 and hot blast stove 4 are fixedly installed on the upper end of chassis car 1, hot blast circulation cylinder 2 and hot blast stove 4 are connected to each other, blower 3 and The hot air circulation cylinder 2 communicates with each other, and the lower end of the chassis car 1 is fixedly connected with an air inlet pipe 5 and a return air pipe 6. The circulation cylinder 2 is connected, the lower ends of the air inlet pipe 5 and the return air pipe 6 are fixedly connected with a hot air cover 7, and the inner end of the hot air cover 7 is fixedly connected with a hot air dispersing plate 8, and the lower end of the hot air dispersing plate 8 is dug with a plurality of evenly distributed air outlets 9. The end of the air inlet pipe 5 is fixed through the hot air cover 7 and communicates with the hot air distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com