Composite lead dioxide anode and preparation method thereof

A technology of lead dioxide and anode, which is applied in the field of electrodes, can solve environmental pollution and other problems, and achieve the effects of good corrosion resistance, high oxygen overvoltage and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

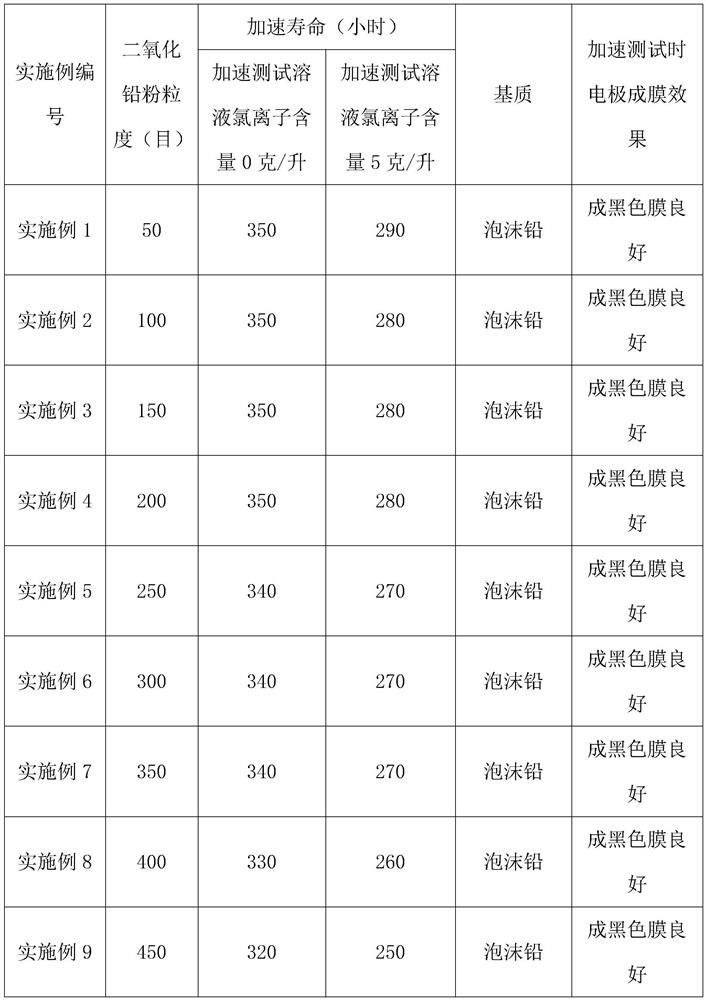

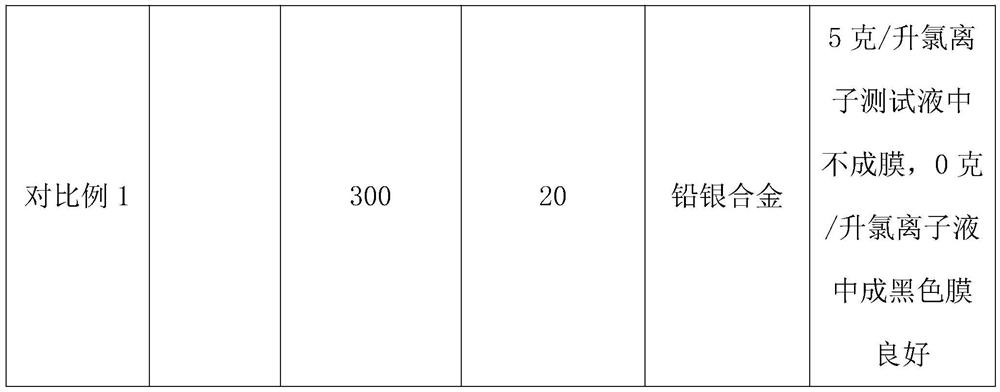

Embodiment 1

[0032]The preparation method of the composite lead dioxide anode of this embodiment includes the following preparation steps:

[0033]1). Collect anode slime: collect the anode slime dropped;

[0034]2) Cleaning anode slime: There are usually metal copper, zinc, cobalt, nickel and other crushed powders in anode slime. Put the mixture in a sloping drum anode bag, insert the insoluble anode and energize, and use 200 g / L sulfuric acid as the electrolyte. Rotating the drum, the anode mud rotates in the drum, contacts the anode and conducts electricity, dissolves the copper, zinc, cobalt, nickel and other metal powders in the anode mud, and the dissolved metal ions are separated by extraction and electrolyzed into pure metal, undissolved Dry the lead dioxide powder for use;

[0035]3) Shaping of lead dioxide powder: test lead dioxide powder particles, determine the ball milling process according to the particle size; ball mill the lead dioxide powder in a ball mill, dry, and sieve to obtain 50% o...

Embodiment 2

[0045]The preparation method of the composite lead dioxide anode of this embodiment includes the following preparation steps:

[0046]1). Collect anode slime: collect the anode slime dropped;

[0047]2) Cleaning anode slime: There are usually metal copper, zinc, cobalt, nickel and other crushed powders in anode slime. Put the mixture in a sloping drum anode bag, insert the insoluble anode and energize, and use 200 g / L sulfuric acid as the electrolyte. Rotating the drum, the anode mud rotates in the drum, contacts the anode and conducts electricity, dissolves the copper, zinc, cobalt, nickel and other metal powders in the anode mud, and the dissolved metal ions are separated by extraction and electrolyzed into pure metal, undissolved Dry the lead dioxide powder for use;

[0048]3) Shaping of lead dioxide powder: test lead dioxide powder particles, determine the ball milling process according to the particle size; ball mill the lead dioxide powder in a ball mill, dry, and sieving to obtain 100...

Embodiment 3

[0058]The preparation method of the composite lead dioxide anode of this embodiment includes the following preparation steps:

[0059]1). Collect anode slime: collect the anode slime dropped;

[0060]2) Cleaning anode slime: There are usually metal copper, zinc, cobalt, nickel and other crushed powders in anode slime. Put the mixture in a sloping drum anode bag, insert the insoluble anode and energize, and use 200 g / L sulfuric acid as the electrolyte. Rotating the drum, the anode mud rotates in the drum, contacts the anode and conducts electricity, dissolves the copper, zinc, cobalt, nickel and other metal powders in the anode mud, and the dissolved metal ions are separated by extraction and electrolyzed into pure metal, undissolved Dry the lead dioxide powder for use;

[0061]3) Shaping of lead dioxide powder: test lead dioxide powder particles and determine the ball milling process according to the particle size; ball mill the lead dioxide powder in a ball mill, dry, and sieving to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com