Self-balancing elevator counterweight device and elevator counterweight self-balancing method

A counterweight device and self-balancing technology, applied in transportation and packaging, lifting equipment in mines, elevators, etc., can solve the problems of electric energy waste and ineffective use of electric energy, and achieve the effect of eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

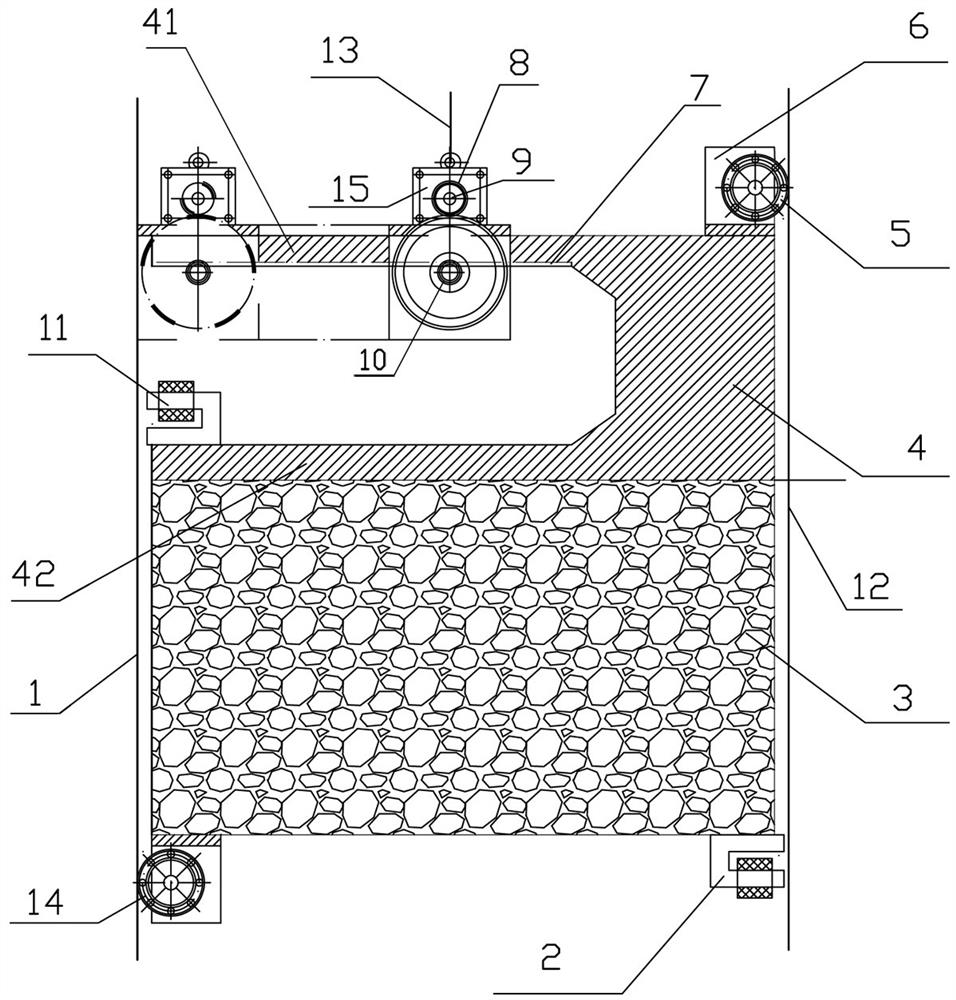

[0016] Such as figure 1 As shown, the self-balancing elevator counterweight device of the present invention includes a counterweight body 3 , an upper beam frame 4 arranged on the top of the counterweight body, and a mobile hanging mechanism for connecting with a traction wire rope 13 . Counterweight body 3 can adopt the form of adorning gravel concrete filler in the metal shell, and its total weight should be less than the empty weight of the elevator car.

[0017] A kind of specific implementation of upper beam frame 4 is designed as figure 1 As shown in a horizontal U-shaped frame, the rack 7 is fixed on the bottom surface of the upper cantilever 41 of the U-shaped frame, and the lower arm 42 of the U-shaped frame is fixedly connected with the counterweight body 3 . Of course, the upper beam frame 4 can also adopt a traditional steel beam connecting frame structure, as long as there is a lateral movement space for the suspension mechanism.

[0018] The rack 7 installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com